Catalyst for synthesizing methacrolein from propionaldehyde and formaldehyde and application thereof

A technology of methacrolein and catalyst, applied in the field of methacrolein catalyst, to achieve the effect of stable content, high content and long service life

Inactive Publication Date: 2014-06-11

中农发河南农化有限公司

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the synthesis methods of MAL mainly include the following several process routes: catalytic oxidation of isobutene, direct oxidation of isobutane, co-production of butene mixture gas phase oxidation 1, 3-butadiene, methacrolein and 2-methyl-2-propen-1-ol catalytic oxidation method, etc. Although these methods have cheap raw materials, the process is relatively complicated, the service life of the catalyst is short, and the discharge of three wastes is large , not suitable for the synthetic production of refined manufacturers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0023] Example 3

Embodiment 2

[0025] Example 4

Embodiment 3

[0027] The average content of methacrolein in the above four examples: 98.15%, the average yield: 98.47%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

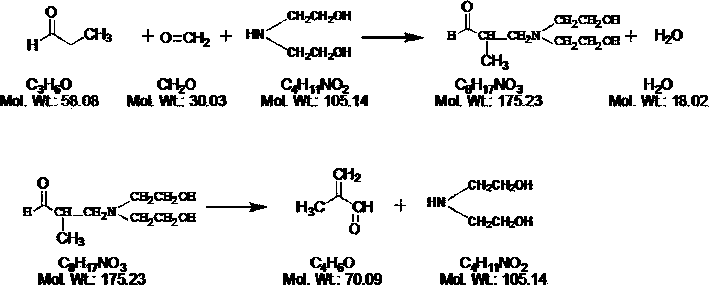

The invention relates to a catalyst for methacrolein and application thereof. The catalyst for synthesizing the methacrolein is composed of the following components: diethanol amine and oxalic acid. The diethanol amine and the oxalic acid are used as the catalyst, and condensation of formaldehyde and propionaldehyde is carried out in normal-pressure, low-temperature and liquid-phase states; a one-step crossed condensation reaction is carried out to obtain methacrolein which is distilled and purified to obtain the methacrolein with the content of more than 98%. Data from comprehensive analysis on the content and yield proves that compared with a target product obtained from a reaction in the presence of a catalyst solution prepared from wastewater, a target product obtained from a reaction in the presence of a catalyst solution prepared from freshwater almost does not fluctuate.

Description

technical field : [0001] The present invention relates to a catalyst for methacrolein and its application. Background technique : [0002] Methacrolein, alias methacrolein, 2-methacrolein, a-methacrolein, English name: 2-Methyl propenal; Metharolein, is a colorless liquid with a strong pungent odor, which is mainly used for copolymerization It is a raw material for the production of methyl methacrylate and thermoplastics, an important intermediate in organic synthesis, and can be used for the production of medicines, pesticides and dyes. [0003] At present, the synthesis methods of MAL mainly include the following processes: catalytic oxidation of isobutene, direct oxidation of isobutane, gas-phase oxidation of butene mixture to co-produce 1,3-butadiene, methacrolein and 2-methyl -2-propene-1-alcohol catalytic oxidation method, etc. Although these methods have cheap raw materials, the process is relatively complicated, the service life of the catalyst is short, and the d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J31/04C07C47/21C07C45/75

Inventor 王作祥秦宏伟董湖斌孙俊玲盛杰

Owner 中农发河南农化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com