Subframe for motor vehicle

A sub-frame and motor vehicle technology, applied in the direction of electric vehicles, electric vehicle charging technology, vehicle components, etc., can solve the problem of increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

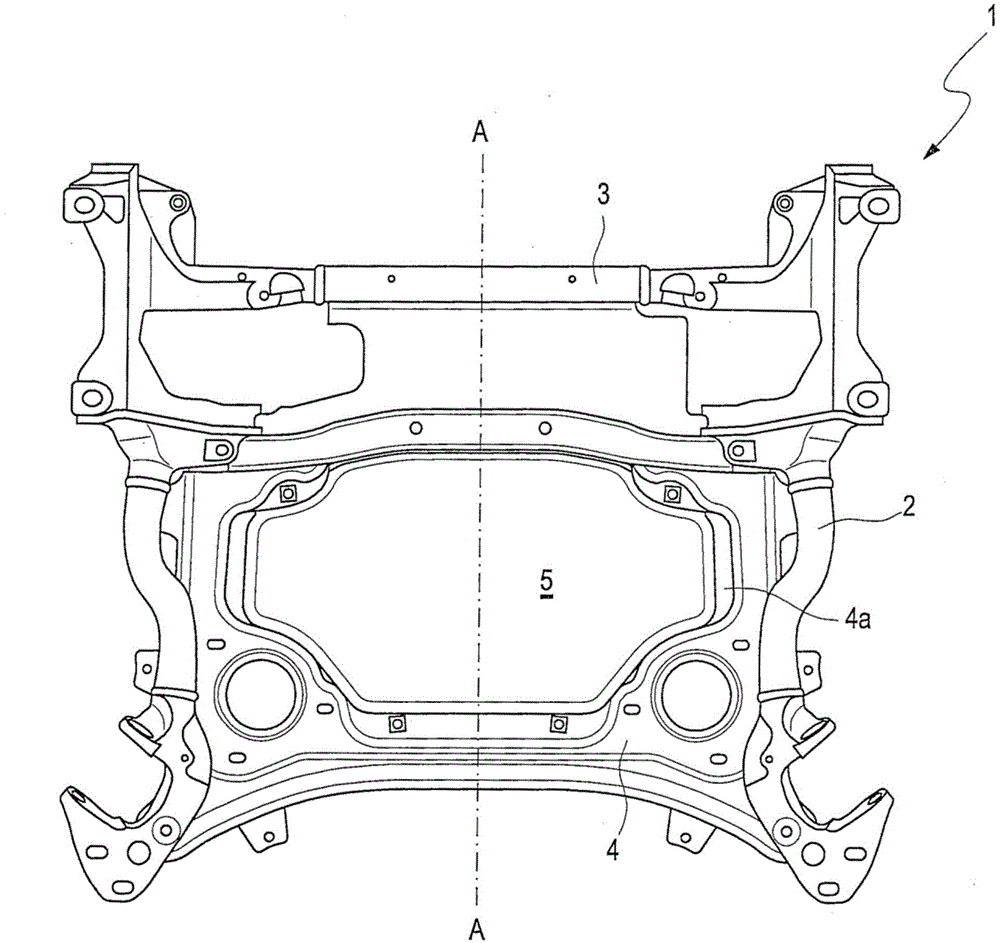

[0031] according to figure 1 A subframe 1 of a motor vehicle comprises two longitudinal brackets 2 arranged mirror-symmetrically with respect to the line of symmetry A-A and spaced apart from each other, and these longitudinal brackets are connected to each other by cross brackets 3 . The reinforcing structure 4 designed as a shear plate for increasing the torsional rigidity is arranged on the subframe 1 configured in this way. The reinforcing structure 4 has a free surface 4a in its center. Mounted on this free surface 4 a is a charging module 5 which, in the installed state, terminates as flush as possible on the bottom side with the surrounding reinforcement structure 4 . The charging module 5 thus becomes an integral part of the reinforcement structure 4 and itself contributes to the reinforcement of the subframe 1 .

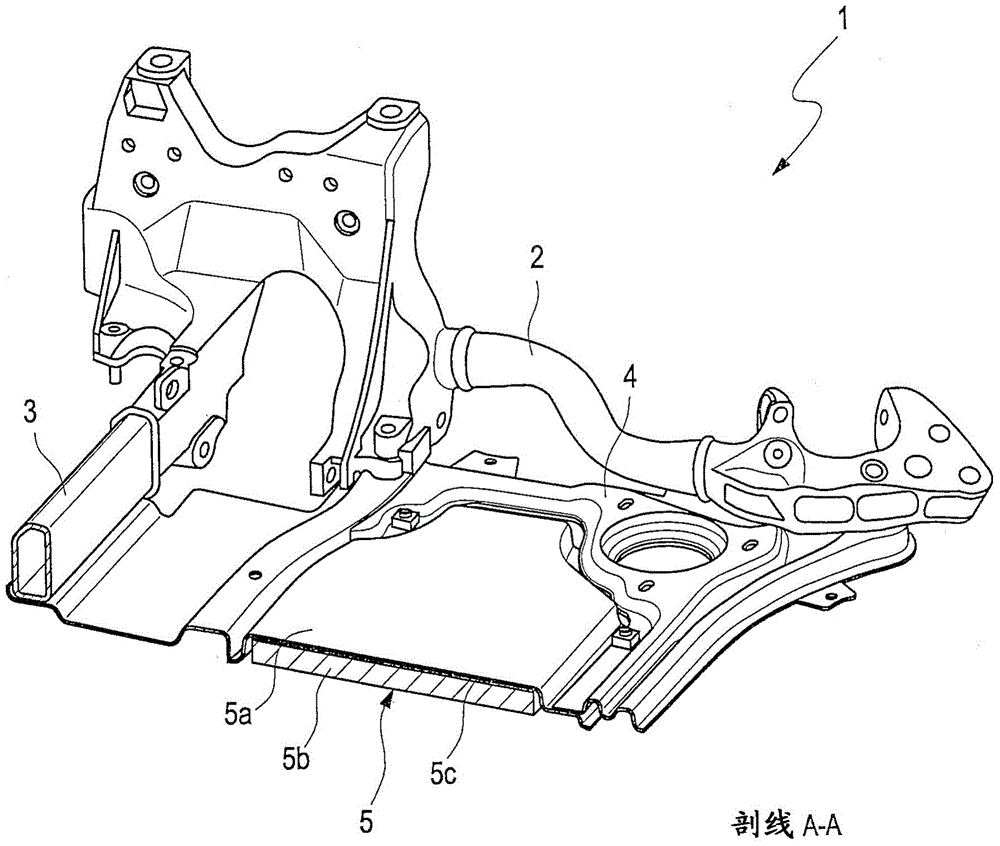

[0032] figure 2 A sectioned half of a subframe 1 with two longitudinal supports 2 and a transverse support 3 is shown. The charging module 5 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com