Retractable cantilever goods shelf

A shelf and cantilever technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of small space for placing goods, reduce the utilization rate of warehouse space, and high difficulty in operation, so as to facilitate forklifts to pick up goods, improve space utilization, The effect of reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

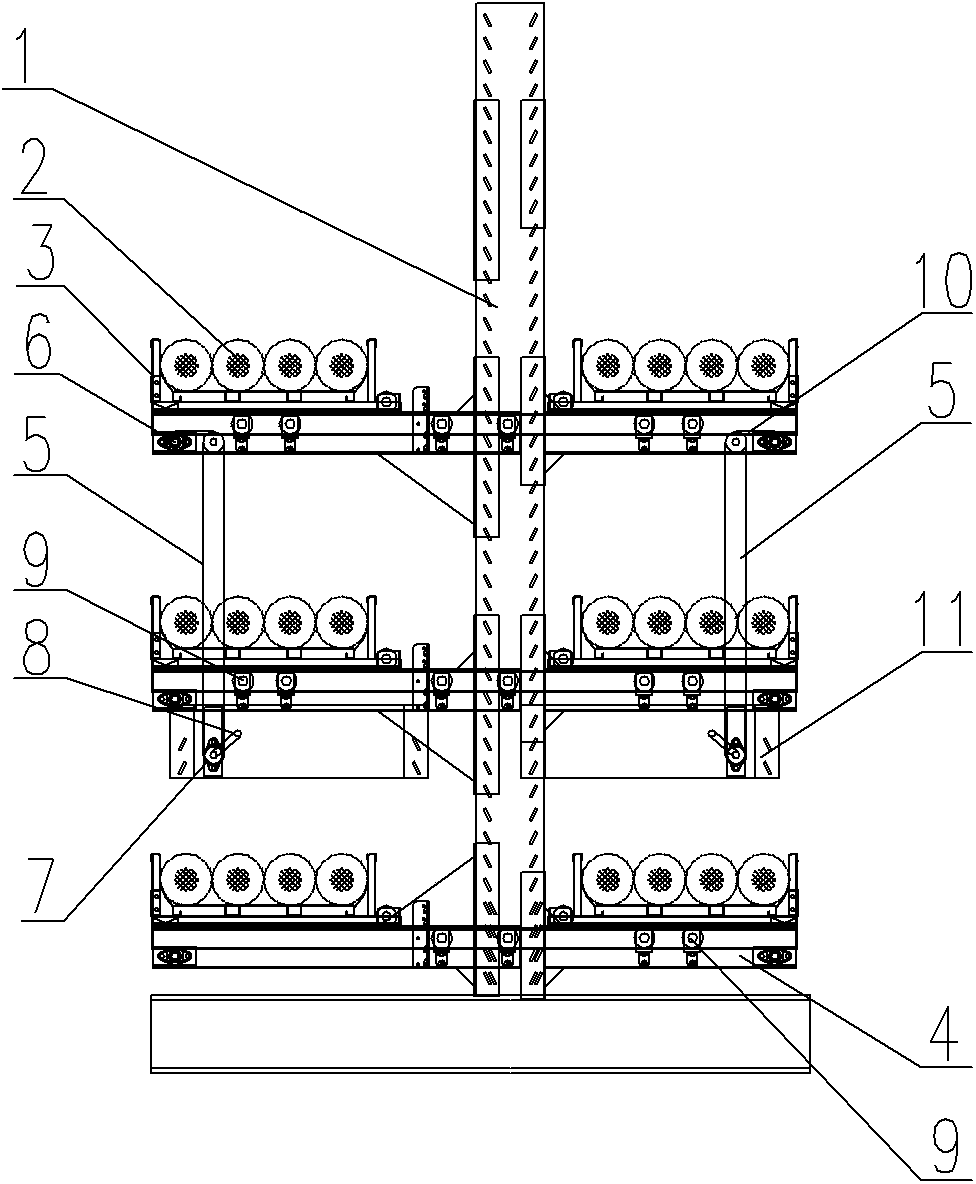

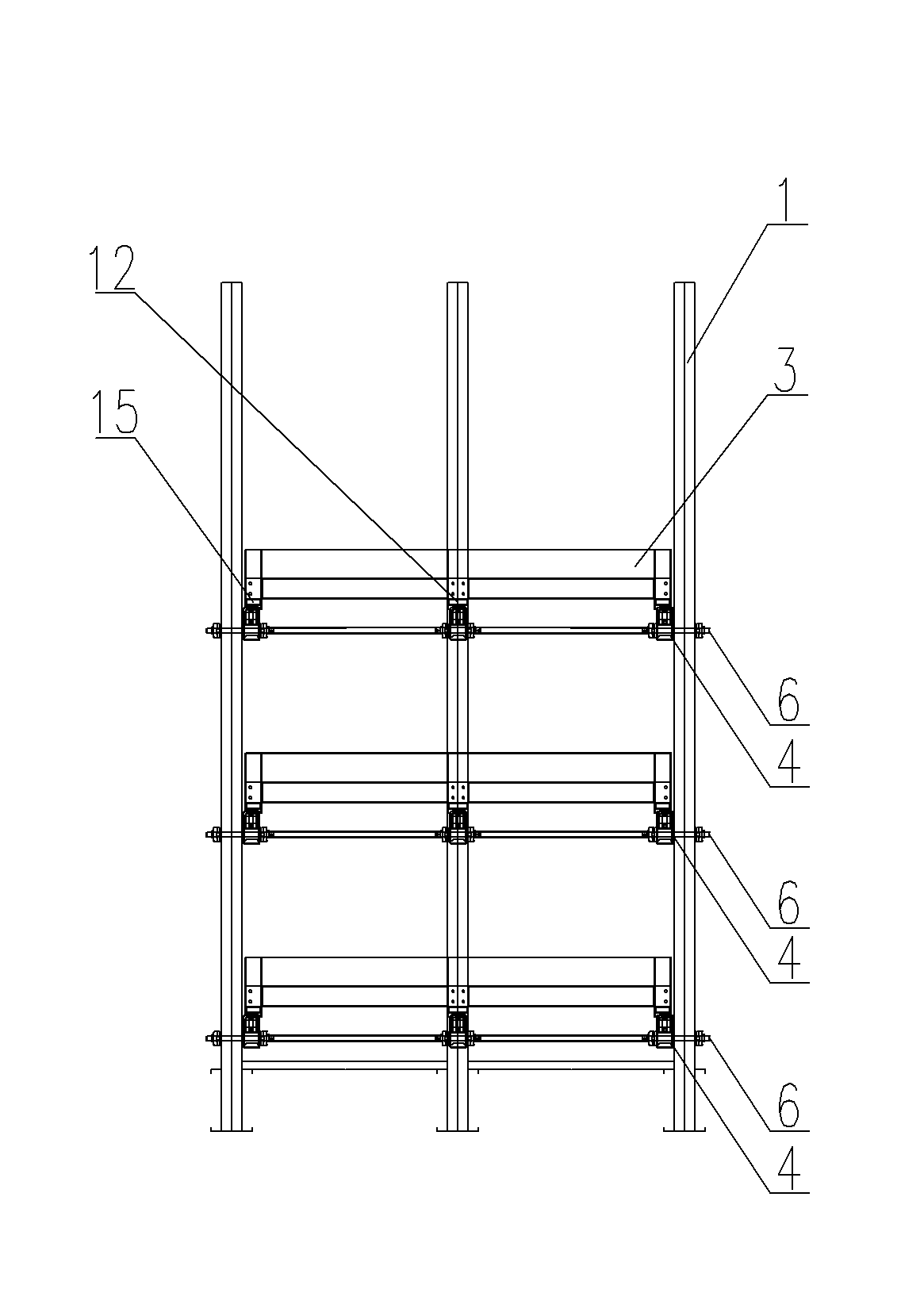

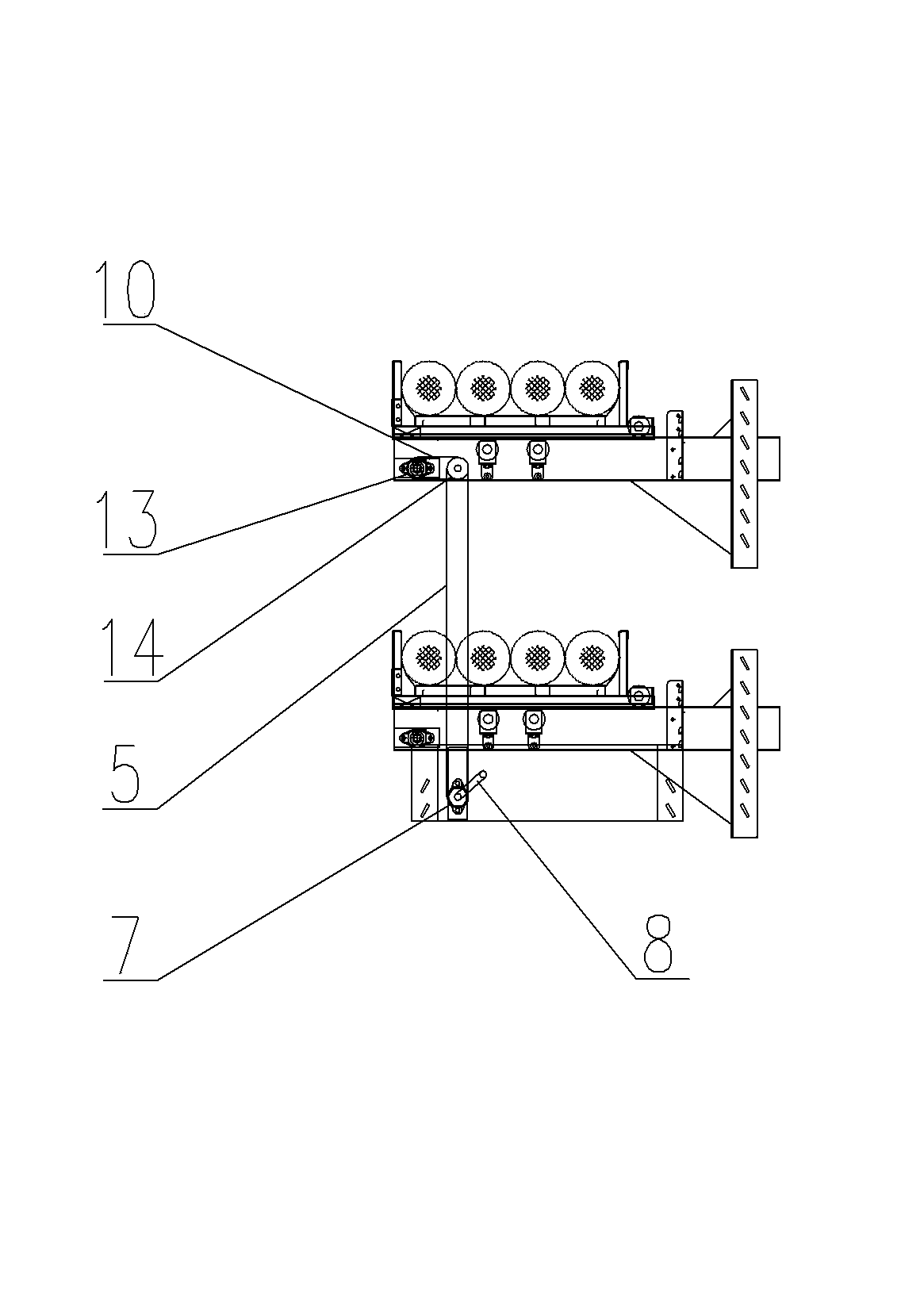

[0012] Such as figure 1 and figure 2 As shown, a telescopic cantilever shelf includes a cantilever shelf main frame 1, a slide rail 4 and a mobile frame 3, the slide rail 4 is installed on both lateral sides of the cantilever shelf main frame 1, and the mobile frame 3 is installed on the slide rail 4. The pulley block 9 is installed in the rail 4, the bottom of the mobile frame 3 and the corresponding slide rail 4 are equipped with chute 12, 15, and each layer of slide rail 4 is connected with a transmission shaft 6 that drives the mobile frame 3 to move laterally, and is located at the upper end of the main frame 1 of the cantilever shelf The transmission shaft 6 is driven by a hand-operated mechanism installed on the lower end of the cantilever shelf main frame 1. The transmission shaft 6 is installed with a driving wheel in the slide rail 4; The three times from top to bottom and the bottom are slide rail three, slide rail two and slide rail one; the rocking mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com