Feeding device for steel pipe flaw detectors

A technology of feeding device and flaw detector, which is applied in the direction of material inspection products, conveyor objects, transportation and packaging, etc. It can solve the problems of inconvenient and unstable feeding, and achieve the effect of avoiding left and right movement and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

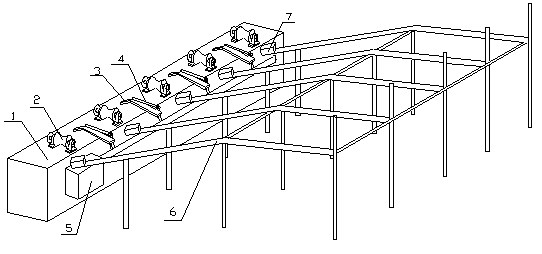

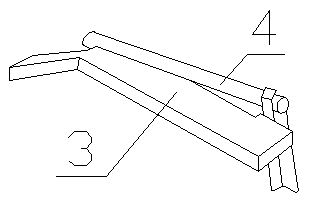

[0012] like figure 1 , 2 As shown, the feeding device of a steel pipe flaw detector according to the present invention includes a cuboid workbench 1, the upper surface of the workbench 1 is uniformly provided with rollers 2, and the middle part of the rollers 2 is concave, and all are driven by motors. Driven to rotate in the same direction, a material retrieving rod 3 is arranged in the middle of every two said rollers 2, said retrieving rod 3 is V-shaped, and the rod body is connected with the rotating shaft 4, and all said rotating shafts 4 are formed by a Driven by the table cylinder 5, the cylinder 5 is installed on the side of the workbench 1, and the ground on the side of the cylinder 5 is provided with a material rack 6, and the material rack 6 is placed in parallel with the workbench 1. The upper plane of the frame 6 is inclined downward at a certain angle near the side of the workbench 1, and the end inclined downward is located above the rod body of the cylinder 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com