Lighting device for elevator car

A technology of elevator car and lighting device, which is applied in the directions of transportation, packaging, elevators, etc., can solve the problems of affecting the appearance, low replacement efficiency, etc., and achieve the effect of improving the appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described below with reference to the drawings. The present invention is not limited to the following embodiments, and various modifications and application examples of the technical concept of the present invention are also included in the scope of the present invention.

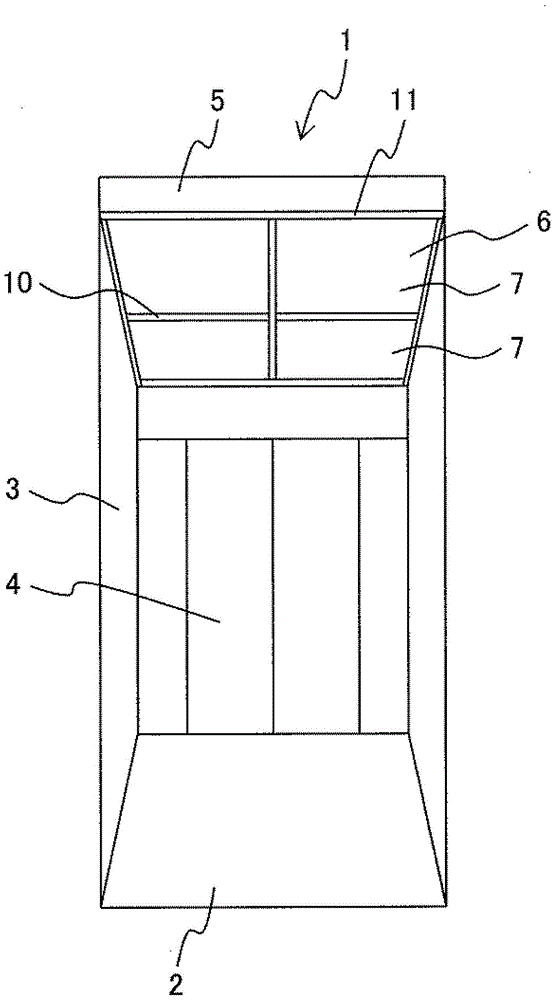

[0026] like figure 1 As shown, an elevator car 1 has a floor 2 , side panels 3 erected on the floor 2 , elevator doors 4 as entrances and exits, a ceiling 5 forming the top, and lighting devices 6 arranged on the ceiling 5 . The illuminating device 6 includes a milky-white light-transmitting plate 7 made of acrylic resin, and in this embodiment, the light-transmitting plate 7 is divided into four light-transmitting plates. The light-transmitting plate 7 is configured such that each outer peripheral edge thereof is supported by a cross-shaped center seam member 10 so as not to fall down.

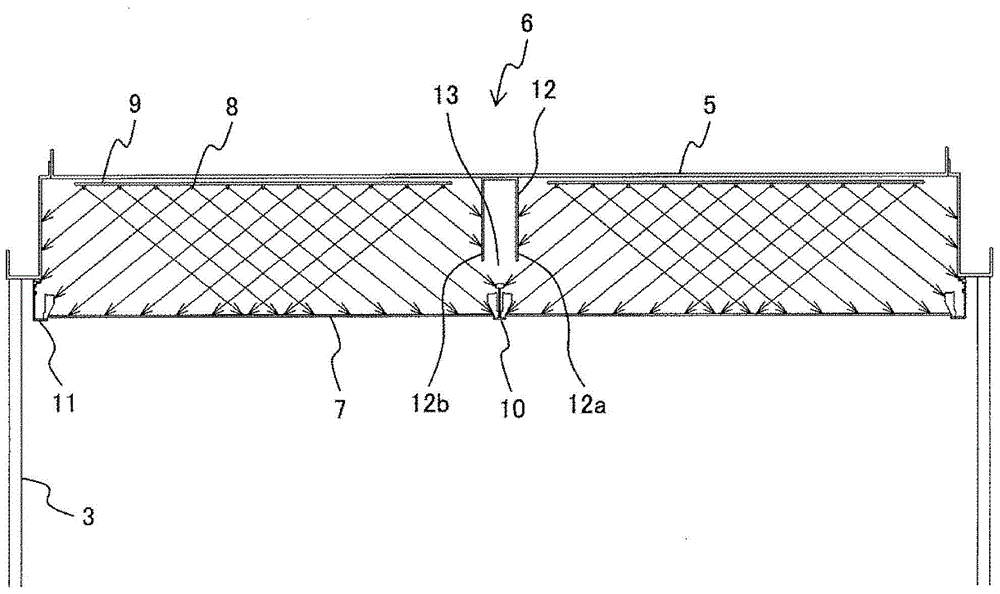

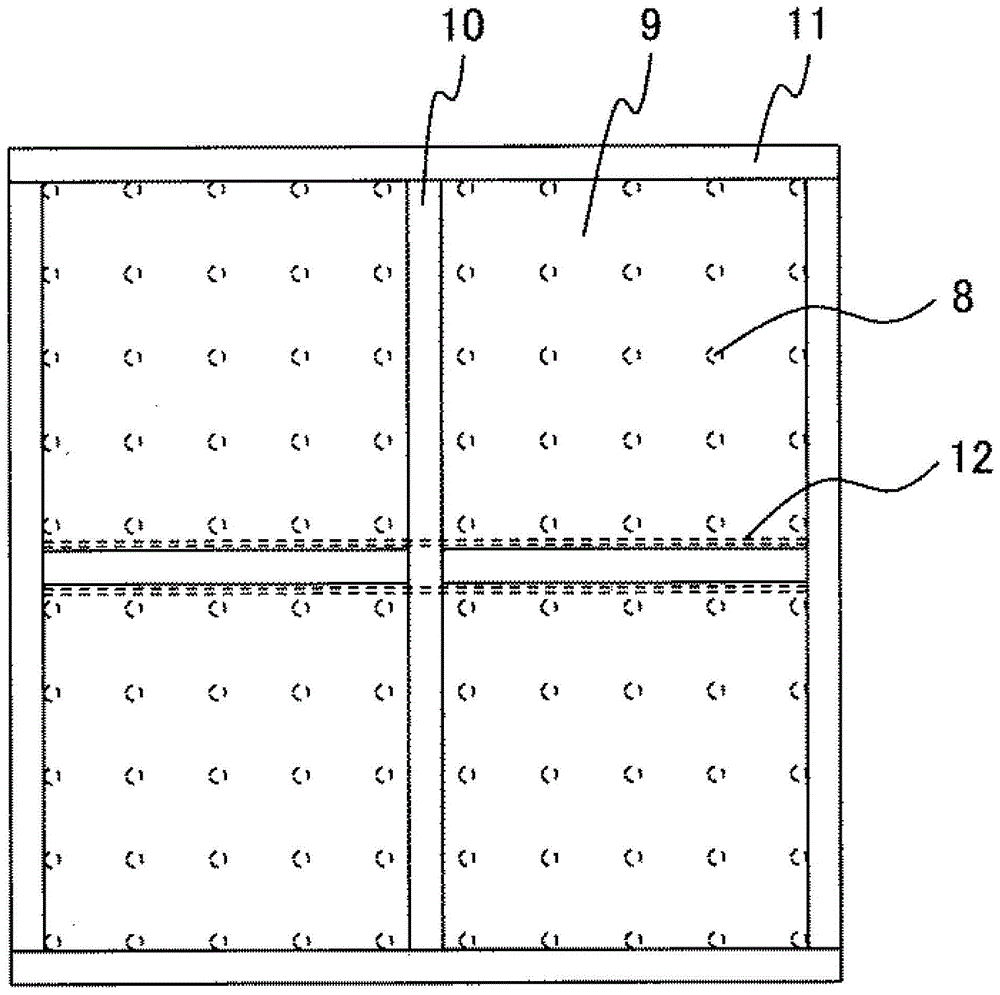

[0027] like figure 2 and image 3 As shown, the lighting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com