Detachable cable anchorage sealing structure and method for realizing anchorage sealing

A sealing structure and internal sealing technology, which is applied to structural elements, building components, building structures, etc., can solve problems such as oil leakage, affect maintainability, and operation difficulty is not reduced, so as to achieve completely reliable sealing and reduce construction difficulty , Easy to control the effect on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

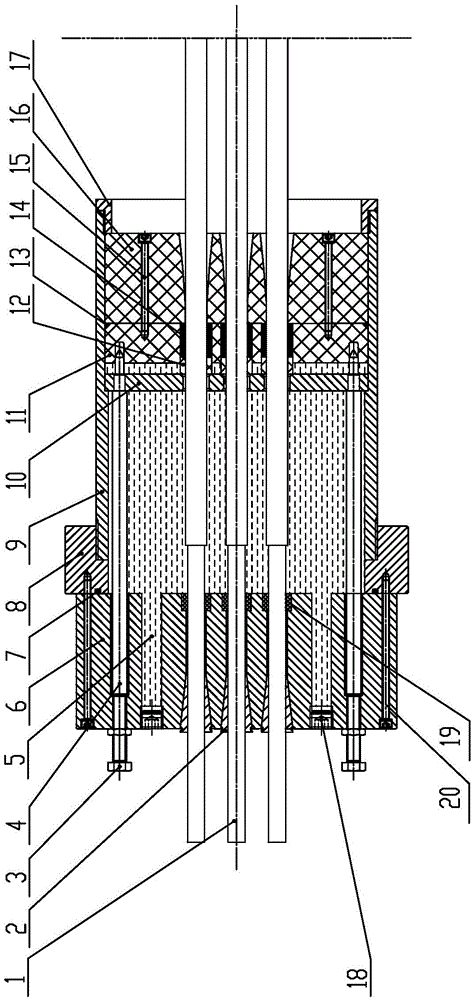

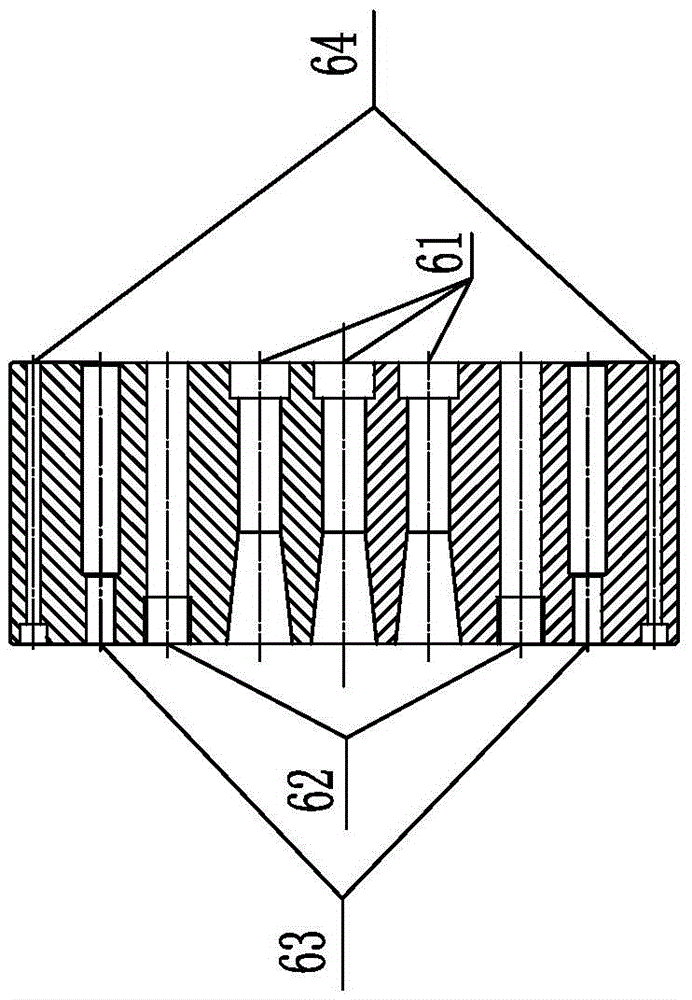

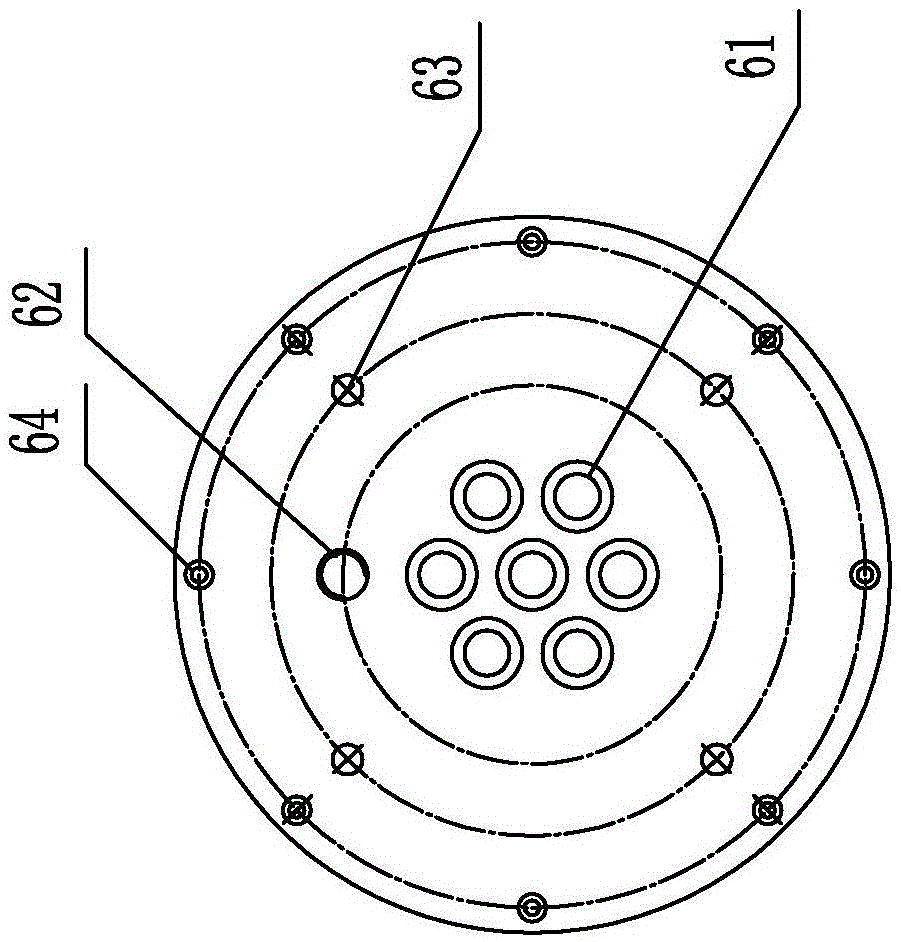

[0078] A detachable cable anchor sealing structure, such as figure 1 As shown, the detachable sealing structure of the cable anchor includes the sealing structure of the anchor head end and the sealing structure inside the anchor head, and the sealing structure of the anchor head end includes an anchor plate 6, a backing plate 8, The O-shaped sealing ring I7 installed on the backing plate 8 has anchor holes 61 inside one end surface of the anchor plate 6 for placing the clip 2 to anchor the steel strands. The number of anchor holes is the same as the number of steel strands. The front section of the hole 61 is a tapered hole, the rear section is a straight hole, and the straight hole has a step. The anchor plate 6 is opened with one in and one out. Through hole Ⅲ64 for installing connecting screws (see Figure 2-1~Figure 2-2 ), the other end surface of the anchor plate 6 is in close contact with the backing plate 8;

[0079] One end surface of the backing plate 8 is in clos...

Embodiment 2

[0095] A method for internal sealing of a cable anchor, which uses the detachable cable anchor sealing structure described in Embodiment 1 to realize the internal sealing of the anchor. The installation and construction steps are as follows:

[0096] A. Install the sealing structure of the anchor head end:

[0097] ① Install anchor plate 6, backing plate 8 and sealing cylinder 9 in sequence

[0098]Place the O-ring I7 in the ring-shaped sealing groove 81 of the backing plate 8, and place one end of the backing plate 8 with the O-ring I7 in close contact with the anchor plate 6, and the other end and the sealing cylinder 9 in a threaded manner Connect, apply sealant to the joint;

[0099] B. Install the sealing structure inside the anchor head:

[0100] ① Install the compression plate 10, the pressure bearing sleeve 12, the inner sealing plate 11, the outer sealing plate 16 and the compression ring 17 in the sealing cylinder 9 in sequence, and the sealing cylinder 9 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com