Floor component

A floor and component technology, applied to floors, pavements paved with prefabricated blocks, roads, etc., can solve the problems of unsuitable indoor floor pavement, difficult to clean, debris falling into the gap, etc., and achieve a simple paving method , height adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

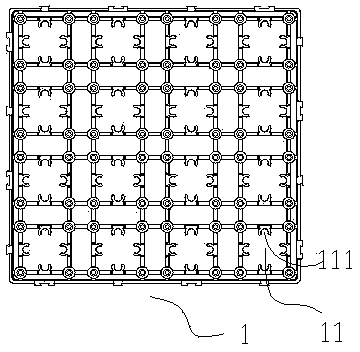

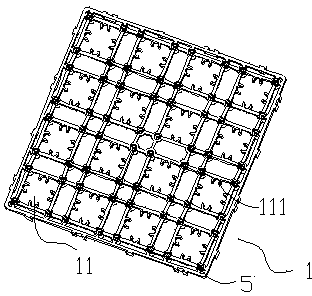

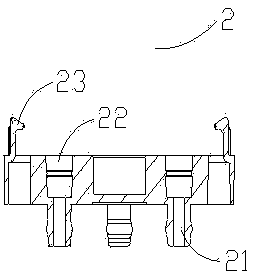

[0041] Such as Figure 1-11 As shown, a floor assembly is composed of a plastic bottom bracket 1 laid on the ground, a plastic fastener 2 fixed on the bottom bracket 1, and a floor 3 fixed on the fastener 2. The bottom bracket 1 and Between the fasteners 2 , and between the fasteners 2 and the floor 3 , there are matching plug-in or clamping structures.

[0042] Among them, the bottom bracket 1 is composed of 4×4=16 square small brackets 11 horizontally and vertically arranged horizontally, and horizontal and vertical spacers 6 with the same width are arranged between adjacent two square small brackets 11 (each square small bracket 11 Holder 11 and an adjacent interval band 6 form a rectangle). The square small holder 11 is in the shape of a hollowed-out frame, and the middle parts of its four frames are each provided with a plugging portion 111 protruding toward the center of the frame body, so that the four plugging portions of each square small holder 11 also form a frame....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com