Centrifugal fan and refrigerator using fan

A centrifugal fan and fan technology, which is applied to the components of the pumping device for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve the problem of reducing air output, air speed, and substandard performance of air-cooled refrigerators. , can not meet the noise requirements and other problems, to achieve the effect of ensuring the air output, good air output and noise reduction ability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

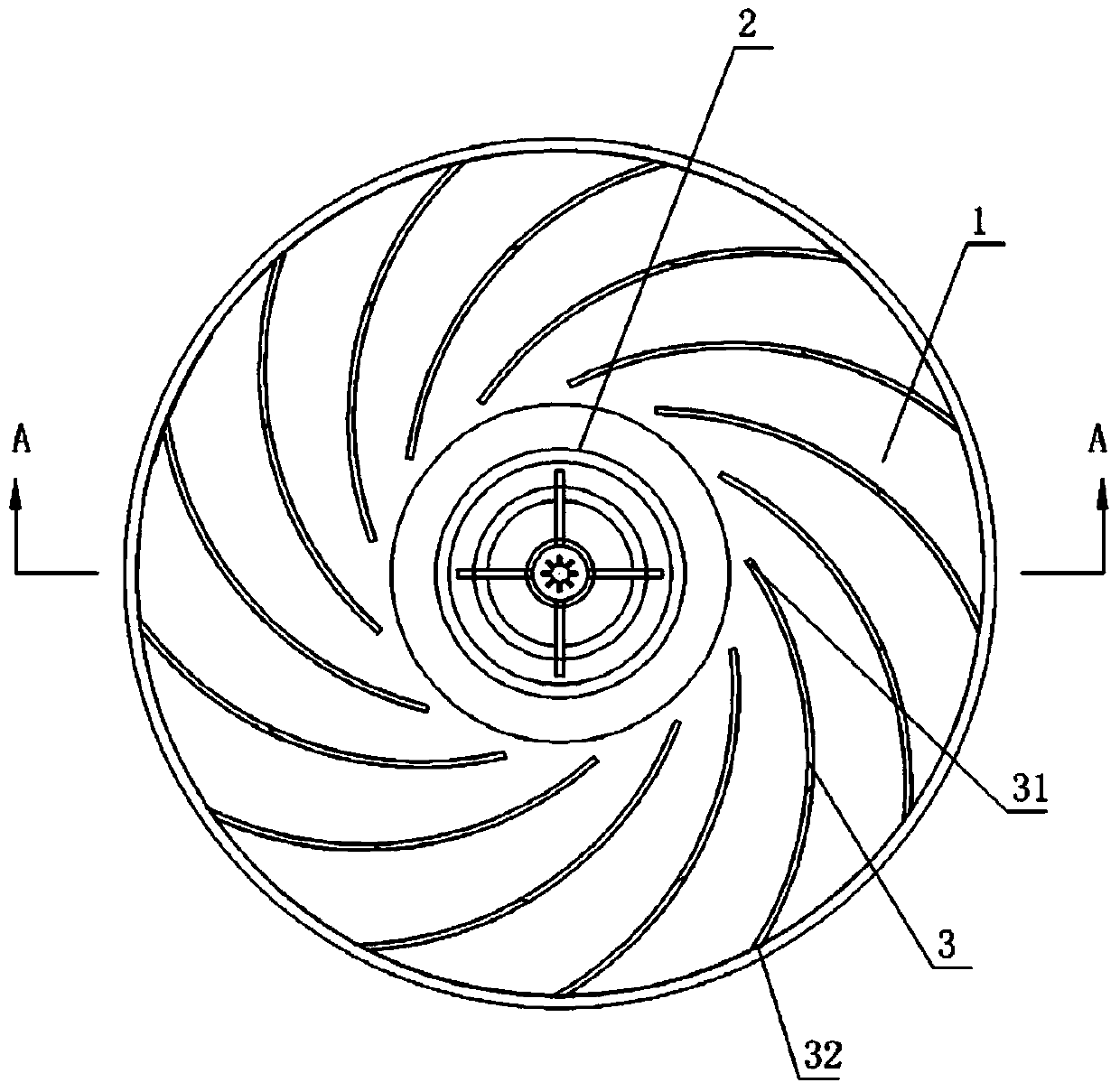

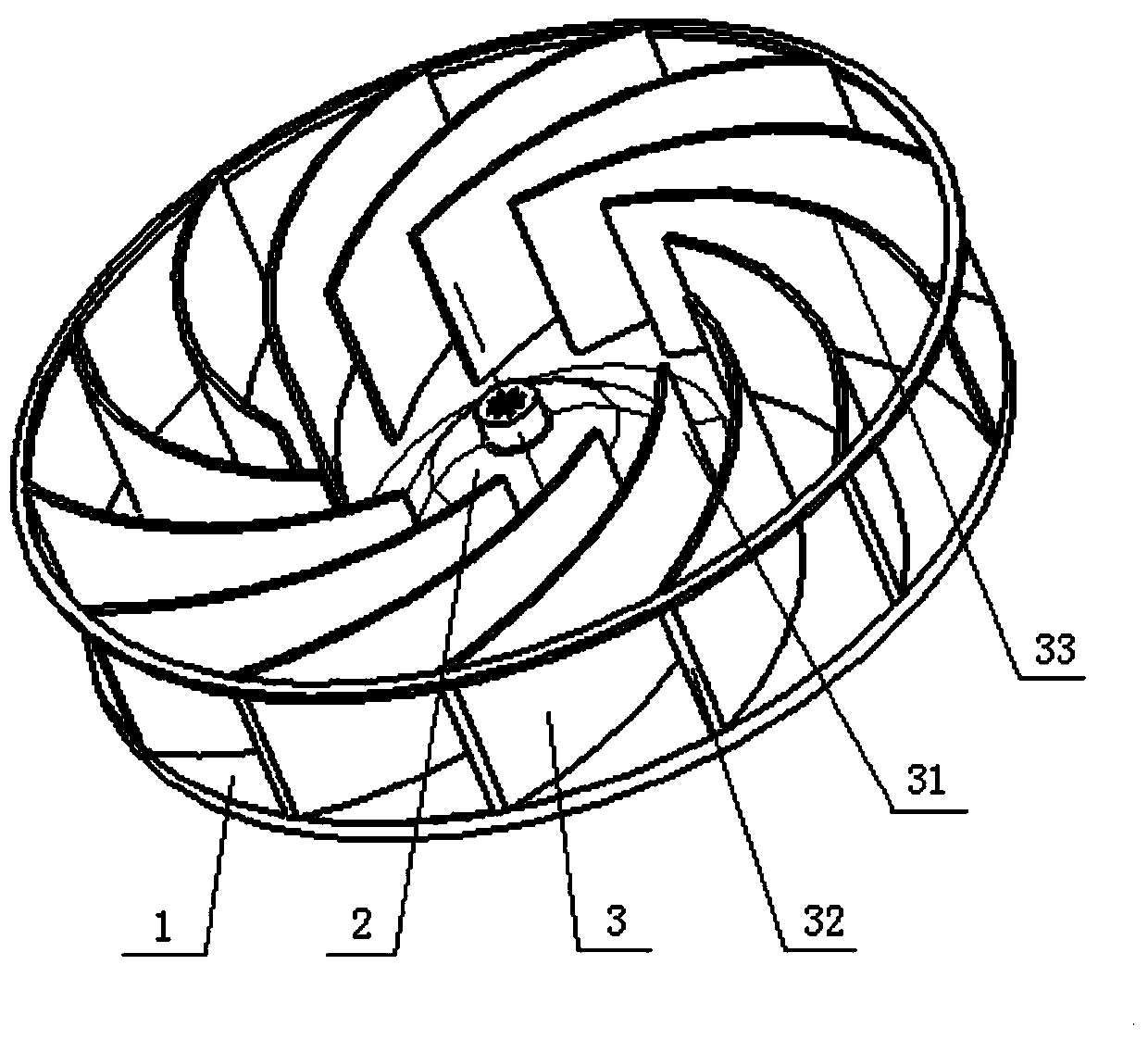

[0026] Such as Figure 1 to Figure 3 As shown, the centrifugal fan of this embodiment includes a chassis 1, an inner hub 2 and a plurality of blades 3, the inner hub 2 is fixed in the middle of the chassis 1, the position of the fan axis, the blades 3 are distributed around the inner hub 2, and the blades 3 are fixed on on chassis 1.

[0027] For the convenience of the embodiment statement, here we define: the end of the blade 3 close to the inner hub 2 is the inner round end, and the end of the blade 3 away from the inner hub 2 is the outer round end, wherein, the inner round end of the blade 3 is the closest side to the inner hub 2 The outer edge 31 is the inner edge 31 , and the outer edge 32 is the farthest side of the outer circular end of the blade 3 and the inner hub 2 . The upper surface of the blade 3 in the axial direction of the fan is the top surface 33 , and the distance from the top surface 33 of the blade 3 to the chassis 1 is the height H of the blade 3 , that...

Embodiment 2

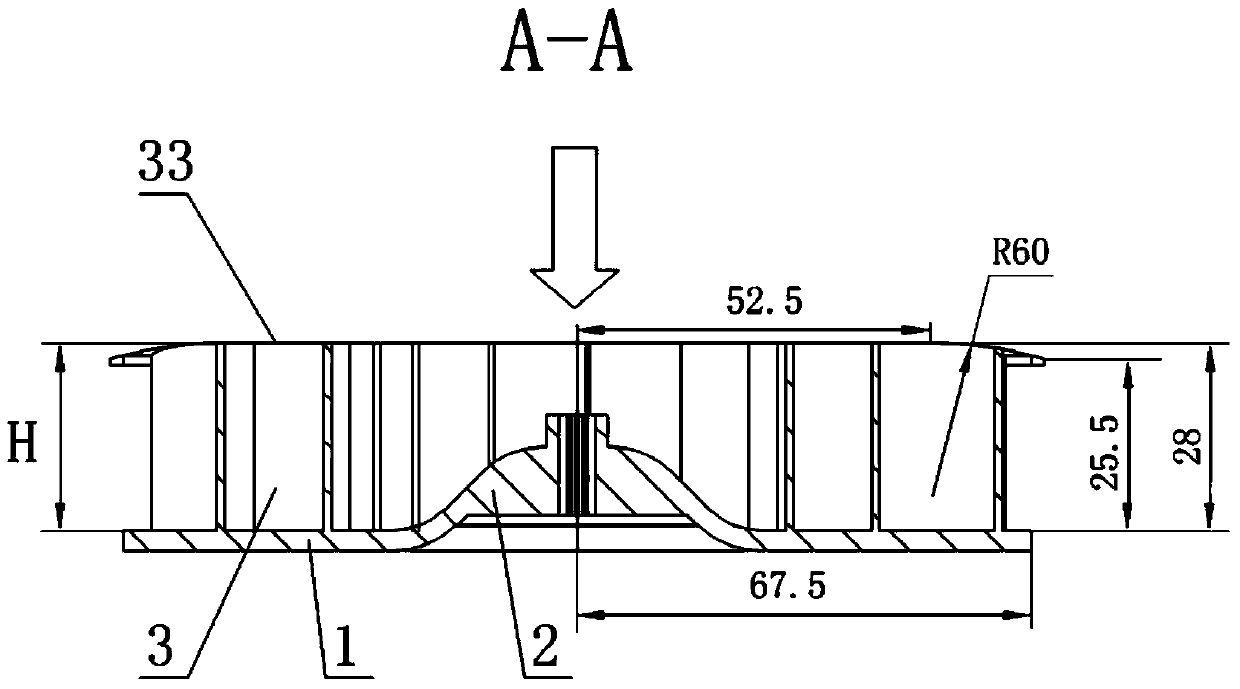

[0037] This embodiment is a further optimization of Embodiment 1. The centrifugal fan of this embodiment is applied in an air-cooled refrigerator. Considering the installation position and installation structure of the centrifugal fan in the refrigerator, and when the size of the centrifugal fan itself changes, The curved shape of the blade 3 will also change accordingly, which is not conducive to factors such as experimental comparison, so for the radius of the fan itself, that is, the radius of the concentric circle three R3, the distance between the inner edge 31 and the center of the inner hub 2, that is, the concentric circle - R1 , the axial height of the inner edge 31 does not change. In this embodiment, the radius of the centrifugal fan is determined to be 67.5 mm, the radius of the concentric circle R1 is 30 mm, and the axial height of the inner edge 31 is 28 mm.

[0038] When the radius of the centrifugal fan is 67.5 mm, it can be seen from Embodiment 1 that the init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com