Electrostatic charge image developing toner

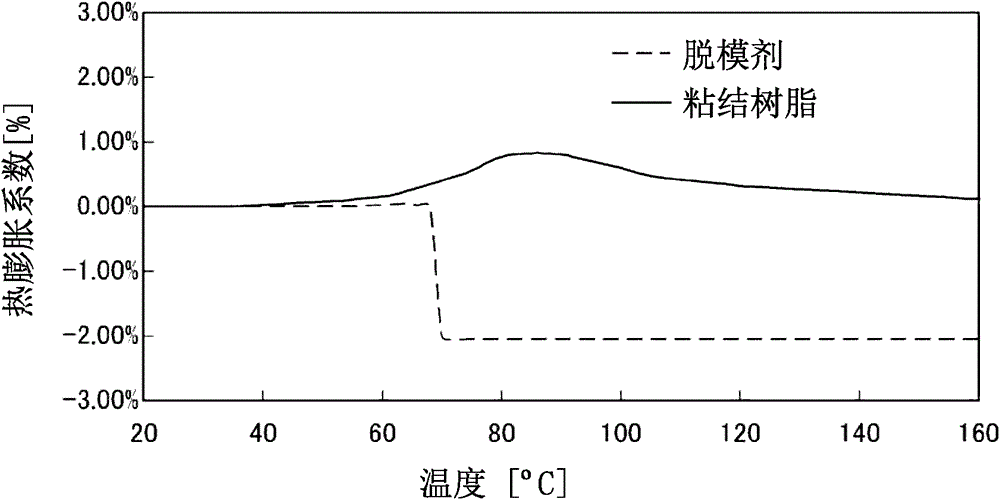

An electrostatic charge image and toner technology, applied in the direction of developer, electrography, optics, etc., can solve the problems that the recording medium is difficult to separate, the toner is easy to agglomerate, etc., and achieves the effect of excellent mold release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] [Manufacturing method of toner for electrostatic charge image development]

[0074] Regarding the production method of the electrostatic charge image developing toner of the present invention, the electrostatic charge image developing toner is obtained by attaching an external additive to the surface of the toner mother particle. In addition, the preparation method of the toner base particles is not particularly limited, as long as the binder resin is mixed with a release agent and, if necessary, a toner base particle containing the above-mentioned components can be prepared. A pulverization method and an aggregation method are mentioned as a preferable manufacturing method of the toner base particle. In the pulverization method, the necessary components (binding resin and mold release agent) are mixed with optional components (colorant, charge control agent and magnetic powder), and melt-kneaded by a single-screw or twin-screw extrusion molding machine. The apparatus ...

Embodiment 1~4、 and comparative example 1~9

[0100] Using a Henschel mixer ("FM-20B" manufactured by Japan Coke Industry Co., Ltd.), with respect to 100 parts by mass of polyester resin ("TUFTONE, NE-7200" manufactured by Kao Corporation) as a binder resin, mixing 5 parts by mass of a release agent of the type described in Tables 3 to 5, 4 parts by mass of a colorant ("Carbon Black, MA-100" manufactured by Mitsubishi Chemical Corporation), 2 mass % of a charge control agent (Orient Chemical "N-01" manufactured by Kogyo Co., Ltd.). Using a twin-screw extrusion molding machine ("PCM-30" manufactured by Ikegai Co., Ltd.), the obtained mixture was melt-kneaded under the conditions of a material supply rate of 5 kg / hour, a shaft rotation speed of 150 rpm, and a cylinder temperature of 150°C. A melt-kneaded product was obtained. The obtained melt-kneaded product was pulverized into a coarse powder using a pulverizer ("ROTOPLEX MILL 8 / 16 type" manufactured by Toa Machinery Seisakusho Co., Ltd.). Next, the coarse powder was pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com