Electrostatic image developing toner and method for producing electrostatic image developing toner

A technology for electrostatic image development and manufacturing methods, which is applied in the directions of developer, electrography, optics, etc., can solve problems such as fogging, difficulty in suppressing fogging, and color spots in formed images, and achieves excellent heat-resistant preservation and suppression bad image effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0015] A first embodiment of the present invention relates to a toner for electrostatic image development (hereinafter also referred to as toner). The toner particles included in the toner for developing an electrostatic image according to the first embodiment are formed by covering the surface of core particles containing a binder resin made of polyester resin with a shell layer. The shell layer is composed of a resin that is a copolymer of monomers including a monomer having a quaternary ammonium group and a (meth)acrylic monomer. The molar ratio of the unit derived from the monomer which has a quaternary ammonium group in a copolymer is 5 mol% or more and 35 mol% or less. The toner of the present invention is composed of toner particles, but may also contain other components.

[0016] The core particles may contain components such as a colorant, a mold release agent, a charge control agent, and magnetic powder in the binder resin as needed. Toner particles may further hav...

no. 2 approach

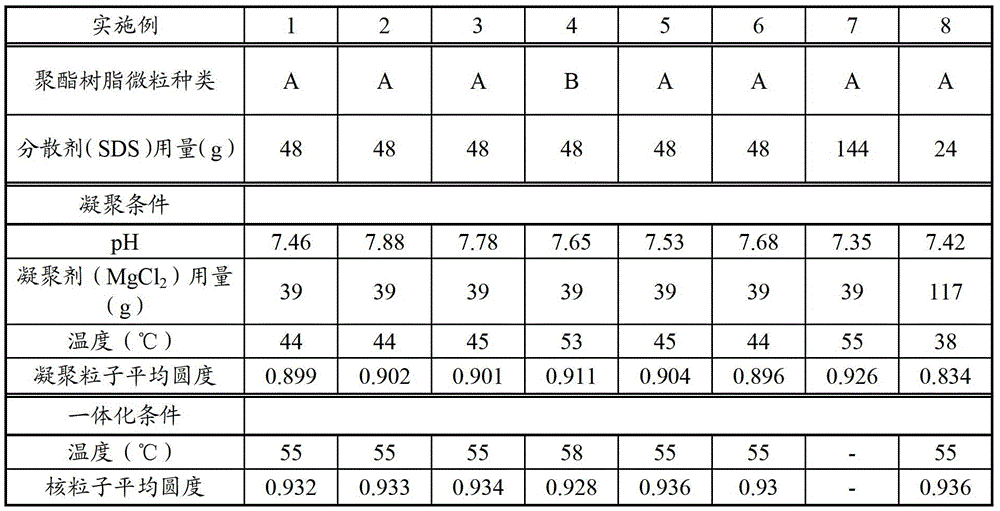

[0104] A second embodiment of the present invention relates to a method for producing an electrostatic image developing toner capable of suitably producing the electrostatic image developing toner of the first embodiment.

[0105] Typical methods for producing toner particles with a core-shell structure including a polyester resin as a binder resin include the following methods. First, core particles containing a polyester resin are dispersed in an aqueous medium in the presence of an anionic dispersant or a nonionic dispersant. Next, fine resin particles are attached to the surface of the core particles. Then, a method of forming a shell layer by forming a film of fine resin particles on the surface of the core particle by heat.

[0106] However, in the conventional method for producing toner particles with a core-shell structure, when fine particles of resin having many quaternary ammonium groups are used as the material of the shell layer, when the resin fine particles are...

preparation example 1

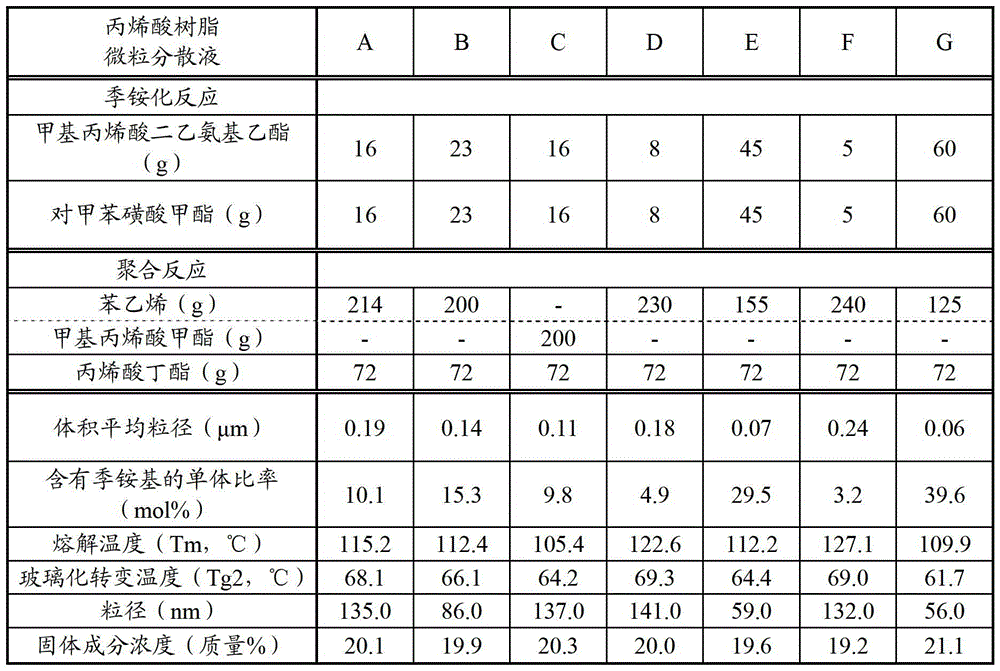

[0176] [Preparation of Polyester Resin Microparticle Dispersion A]

[0177] An aqueous dispersion containing polyester resin microparticles was prepared using the amorphous polyester resin a described below in the following manner.

[0178] (amorphous polyester resin a)

[0179] Melting temperature (Tm): 74.7°C

[0180] Glass transition temperature (Tg1): 37.5°C

[0181] Acid value: 20.5mgKOH / g

[0182] The amorphous polyester resin a was coarsely pulverized to an average particle diameter of about 10 μm using a turbo pulverizer T250 (manufactured by Turbo Industry Co., Ltd.). 100 g of the obtained coarsely pulverized product, 2 g of an anionic dispersant (EMARO (manufactured by Kao Corporation), SDS (sodium dodecyl sulfate)) and 50 g of a 0.1N-sodium hydroxide aqueous solution were mixed. Ion-exchanged water was added to the obtained mixture to prepare a total amount of 500 g of slurry. The resulting slurry was put into a pressure-resistant round-bottomed stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com