Hot-rolled ferritic stainless steel sheet with excellent cold cracking resistance and manufacturing process therefor

A technology for hot-rolled steel sheets and cold cracks, which is applied in the field of ferritic stainless steel hot-rolled steel sheets, can solve problems such as insufficient and effective cold cracks, and achieve the effects of preventing cold cracks, increasing manufacturing yield, and suppressing the use of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

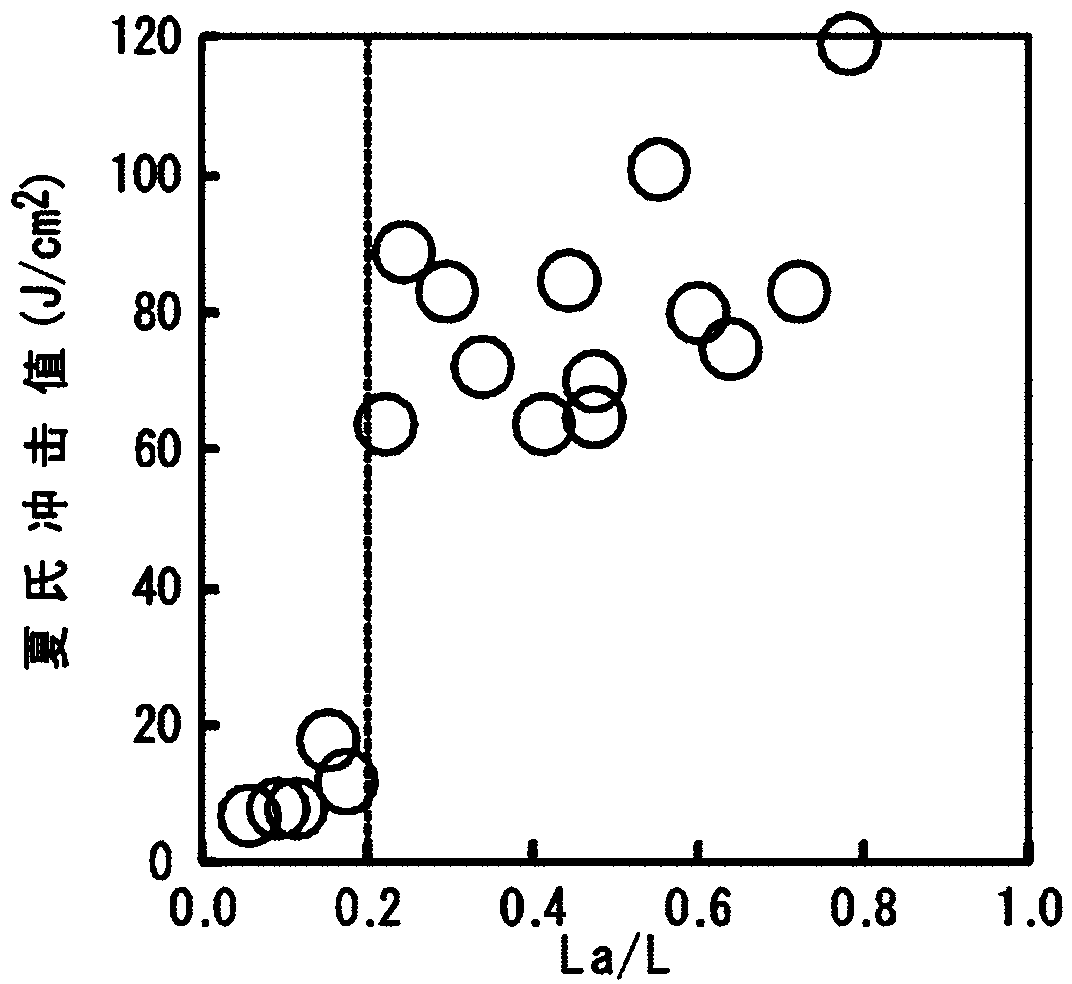

[0100] Hereinafter, the effects of the present embodiment will be described using examples, but the present embodiment is not limited to the conditions used in the following examples.

[0101] In this example, first, each steel having the composition shown in Table 1 was melted and cast to obtain a steel ingot (steel billet).

[0102] The ingot was ground to a thickness of 90 mm. Hot rolling was performed at the finishing temperature (FT) shown in Tables 2 and 3, and the steel ingot was rolled to a plate thickness of 5 mm to obtain a hot-rolled steel plate. Next, while monitoring the temperature of the rolled steel sheet with a radiation thermometer, it was cooled to the coiling temperature (CT) shown in Tables 2 and 3 by water cooling. In addition, the cooling rate at this time was about 20°C / sec.

[0103] Next, the hot-rolled steel sheet was inserted into a furnace whose temperature in the furnace was controlled to the coiling temperature (CT) shown in Tables 2 and 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com