Positioning fixture for repairing welding of workpiece gripped by robot

A technology for positioning tooling and robots, which is applied to manipulators, auxiliary devices, manufacturing tools, etc., can solve problems such as limited scope of application, and achieve the effects of improving the stability of workpieces, ensuring the quality of repair welding, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

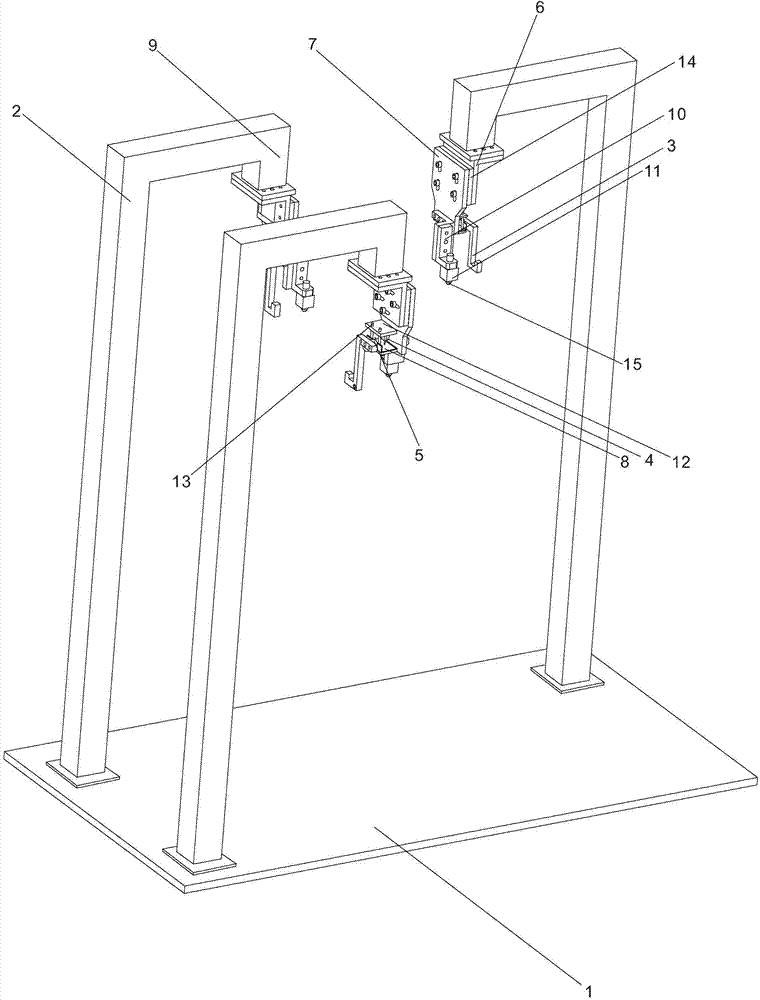

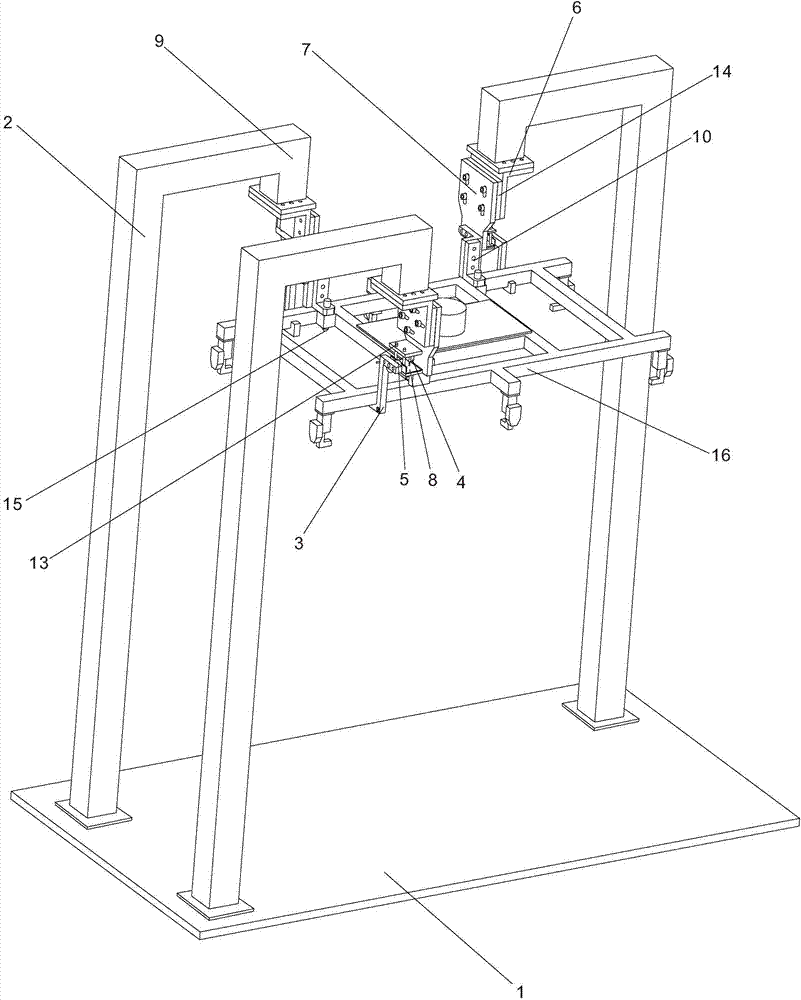

[0019] Such as figure 1 with figure 2As shown in Fig. 1, a robot gripper repair welding positioning tool, the arm of the robot is provided with a robot gripper 16, the frame of the robot gripper is in the shape of "mesh", welded by rods made of square tubes, the robot gripper There are three positioning holes on it. The repair welding positioning tool for the robot grasping parts includes a base plate 1, which is embedded in the ground, and three vertical fixture columns 2 are connected to the base plate 1 through flanges, and the three fixture columns 2 are arranged in an L shape. The top of each fixture column 2 is provided with a bending part 9 bent downward, and the bending part 9 is provided with a robot gripper positioning fixture, and the robot gripper positioning fixture includes a gripper positioning mechanism and a gripper locking mechanism. Described robot gripper location fixture also comprises a column connecting plate 6 and clamp mounting plate 7, is prov...

Embodiment 2

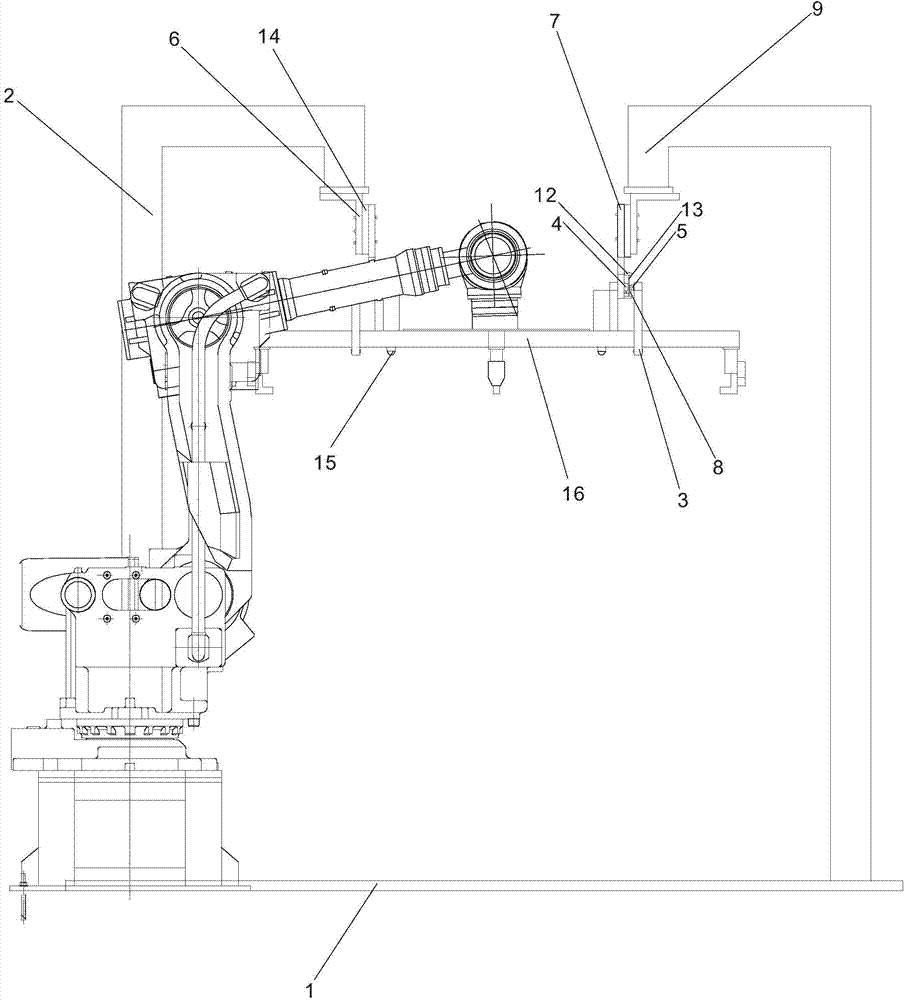

[0022] There are two fixture columns 2, the direction of the parallel slots on the column connecting plate 6 is the vertical direction, the direction of the parallel slots on the fixture mounting plate 7 is the horizontal direction, and there are two positioning pins 15 and two locking hooks 3. When the gripper positioning fixture positions the robot gripper, the positioning pins 15 are separated on both sides of the robot gripper frame, such as image 3 shown. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com