Automatic syringe rubber plug feeding device

An automatic feeding and syringe technology, which is applied in the field of medical device assembly equipment, can solve the problems of easy pollution and low efficiency of manual feeding, and achieve the effects of reducing pollution, facilitating layout and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

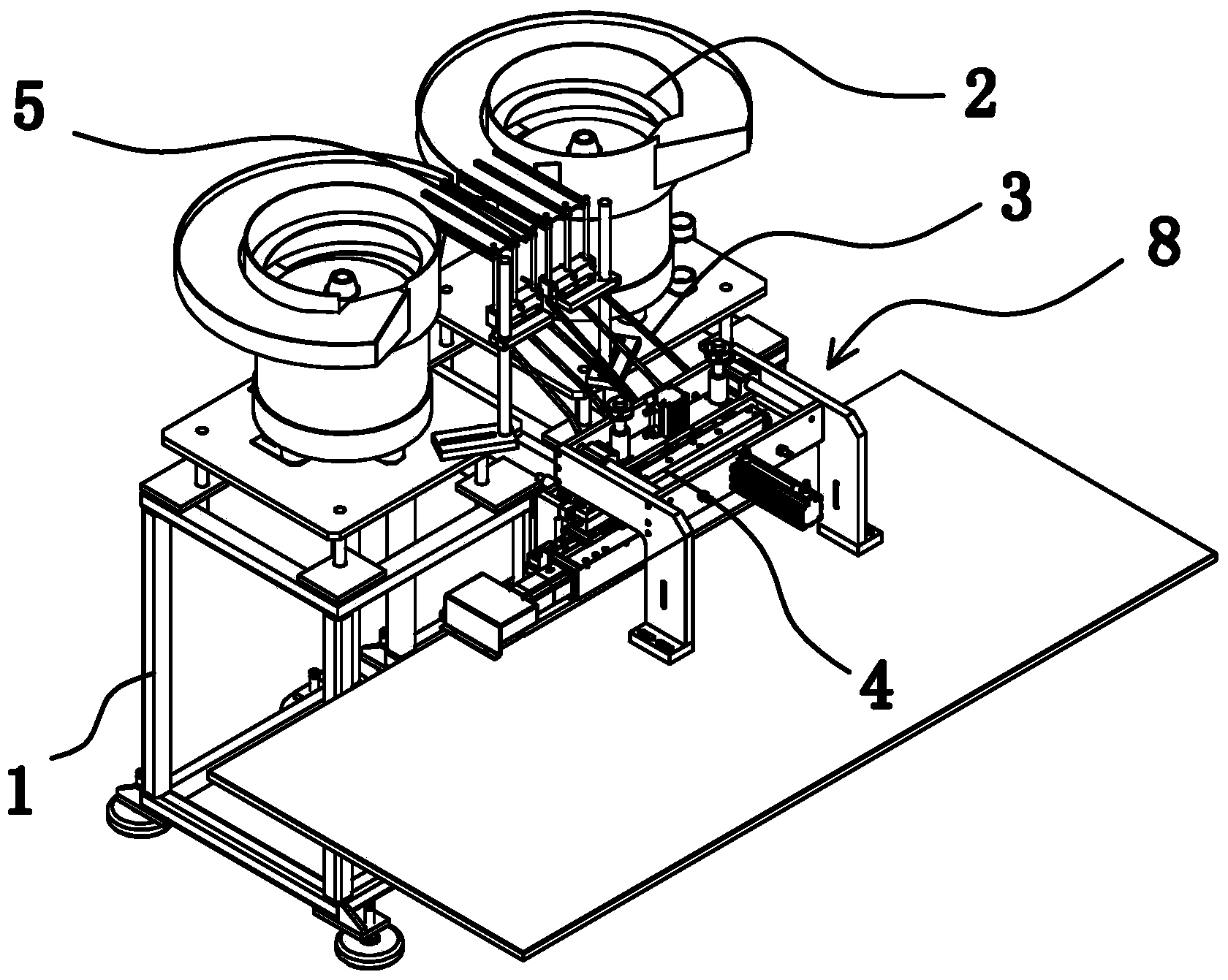

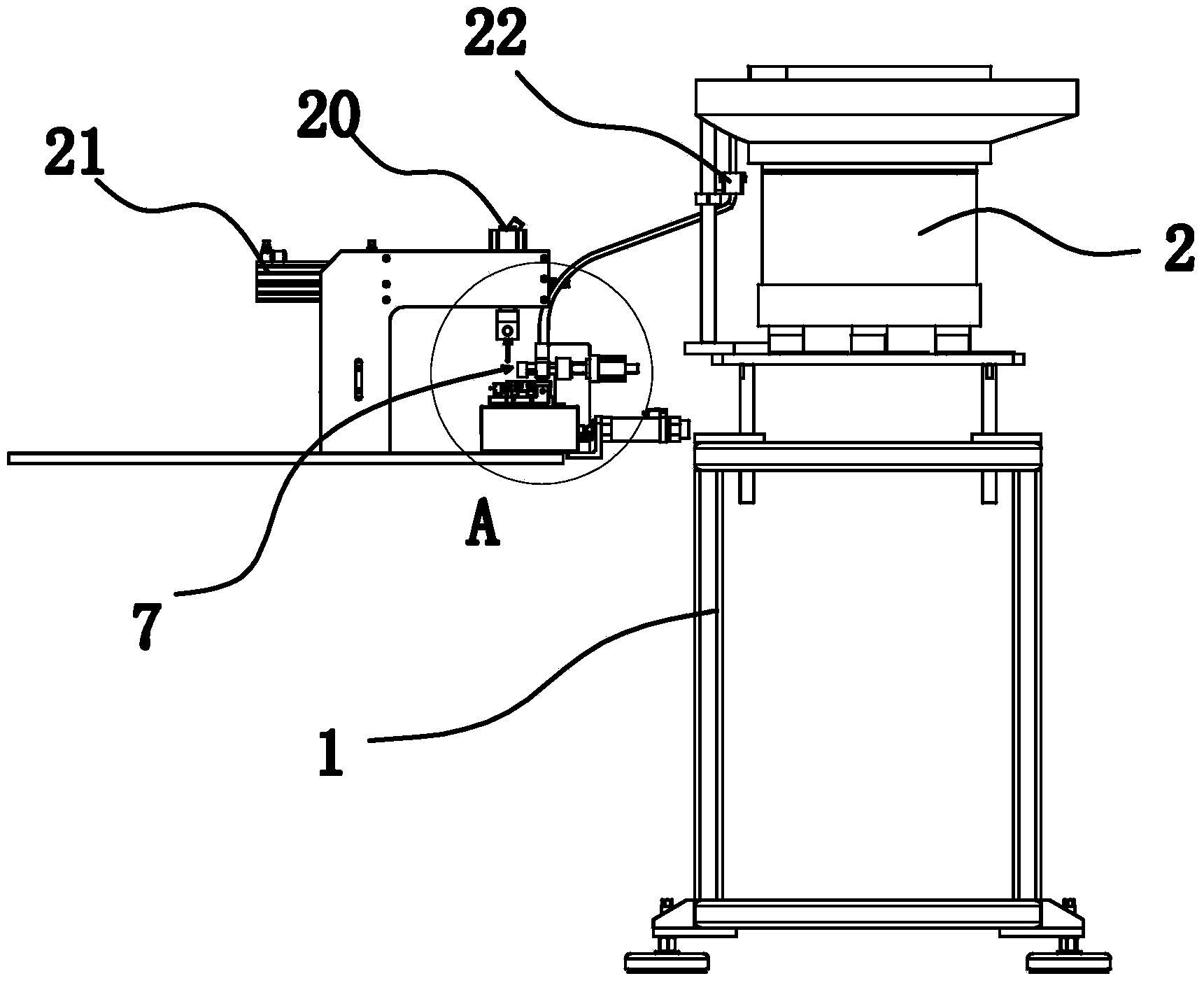

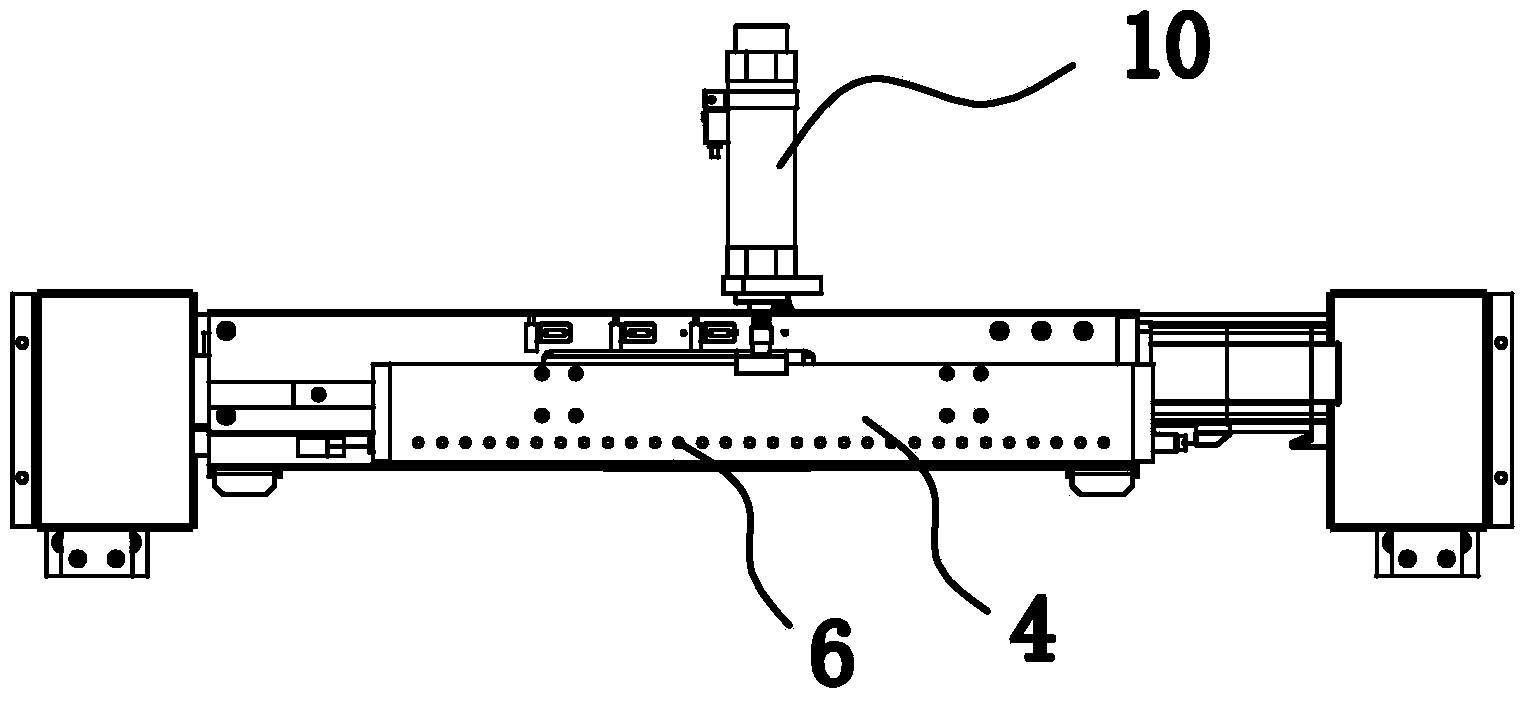

[0024] Such as Figure 1-Figure 6As shown, the feeding device includes a frame 1, a feeder 2, a feed pipe 3 and a positioning plate 4, the feeder 2 has one or a group of output ports 5, the feeder 2 is fixed on the frame 1 and can place the rubber plug Convey in a unified direction and orderly to the output port 5. The positioning plate 4 is located below the feeder 2. The positioning plate 4 is connected to the frame 1 along the horizontal direction and has one or a group of rubber plugs on the positioning plate 4. Positioning holes 6, each output port 5 is connected with a feed tube 3, the feed tube 3 is a hollow body, the upper port of the feed tube 3 communicates with the output port 5, and the lower port of the feed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com