A conveyor line orderly feeding mechanism

A feeding mechanism and conveying line technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of discontinuous incoming materials, large intervals between products, irregularities, etc., and achieve the effect of continuous incoming materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

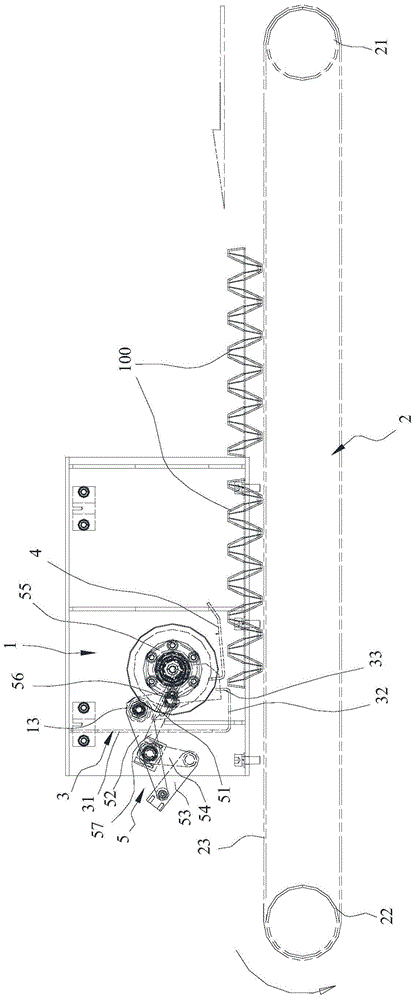

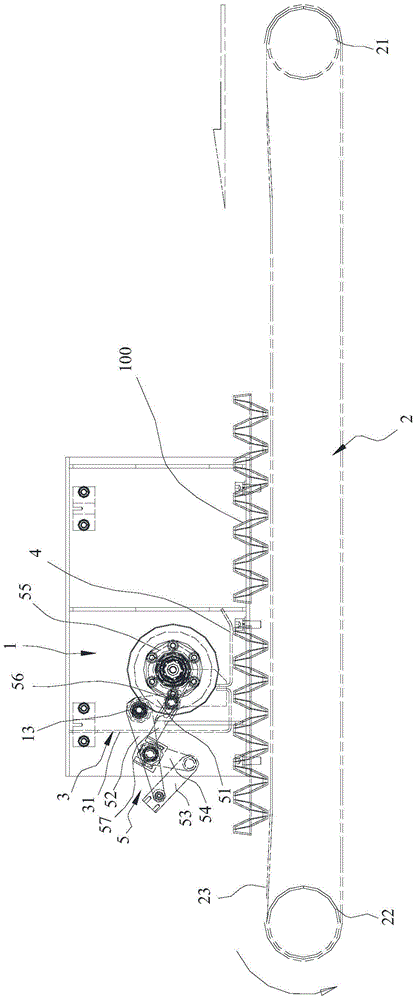

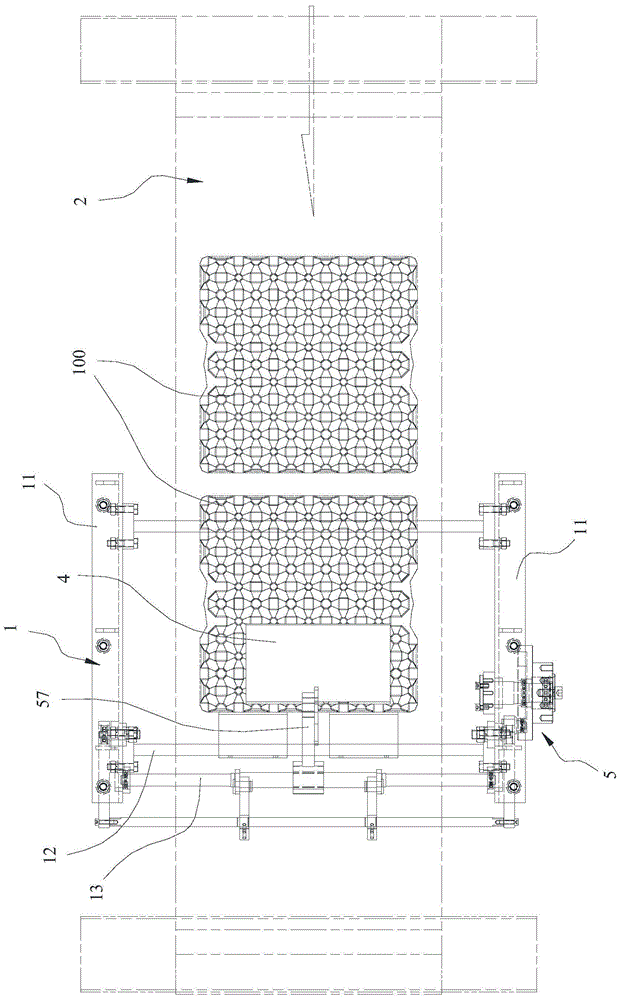

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0023] Such as Figure 1~4 A conveying line orderly feeding mechanism shown includes: a frame 1, a conveying mechanism 2, a baffle plate 3, a pressure plate 4 and a driving mechanism 5, wherein the conveying mechanism 2 includes a driving wheel 21, a driven wheel 22 and The conveyor belt 23 wound around the driving wheel 21 and the driven wheel 22, the conveyor belt 23 is an elastic belt that can be bent and elastically deformed in the vertical direction; the baffle plate 3 is fixed on the frame 1 and extends vertically from the frame 1 To be close to conveyer belt 23, be used for blocking product 100; Holder plate 4, be used for pressing product 100 vertically downward; Switch between a position pressing down on the product 100 and a position detached from the product 100 .

[0024] Product 100100 of the present utility model can preferably adopt pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com