An orderly feeding mechanism for conveying line

A technology of conveying line and transmission mechanism, applied in the field of orderly discharging mechanism, can solve the problems of discontinuous incoming materials, affecting processes, irregularities, etc., and achieve the effect of continuous incoming materials and ensuring smooth progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

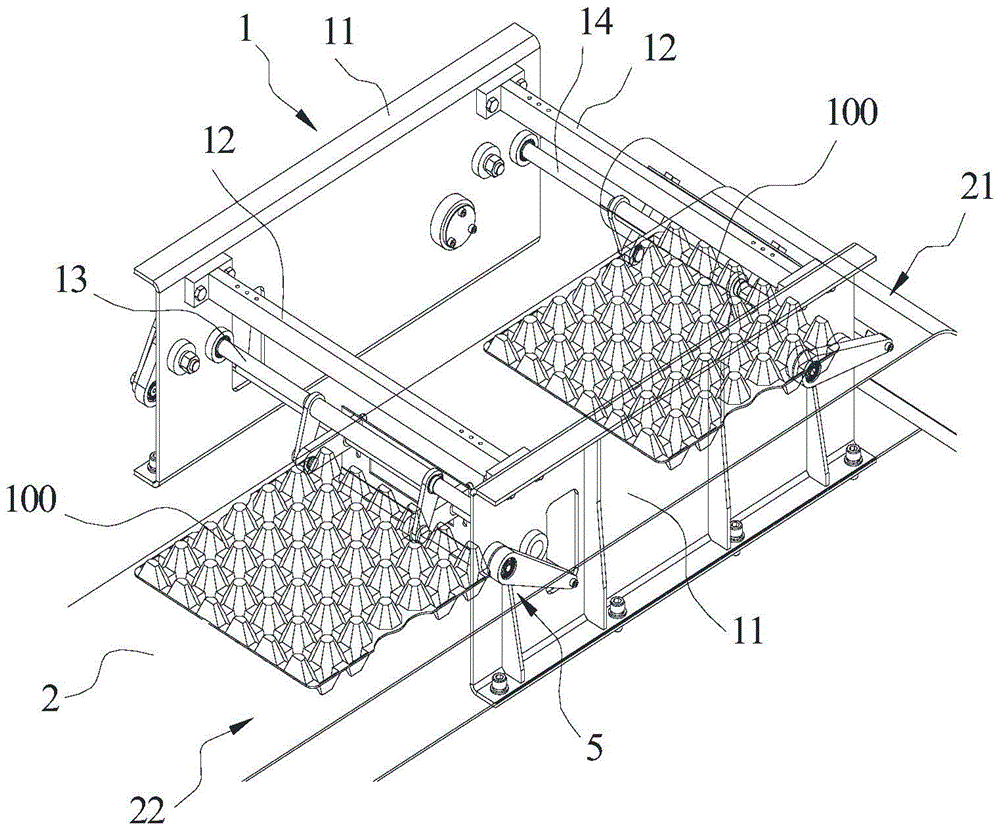

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

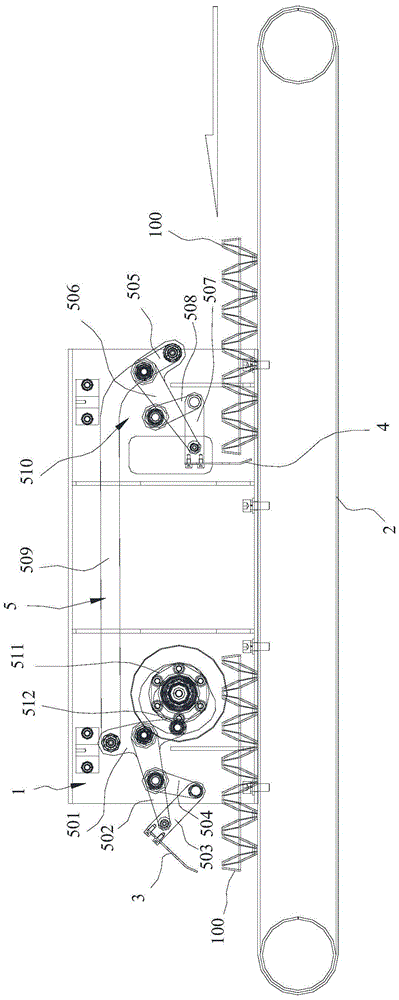

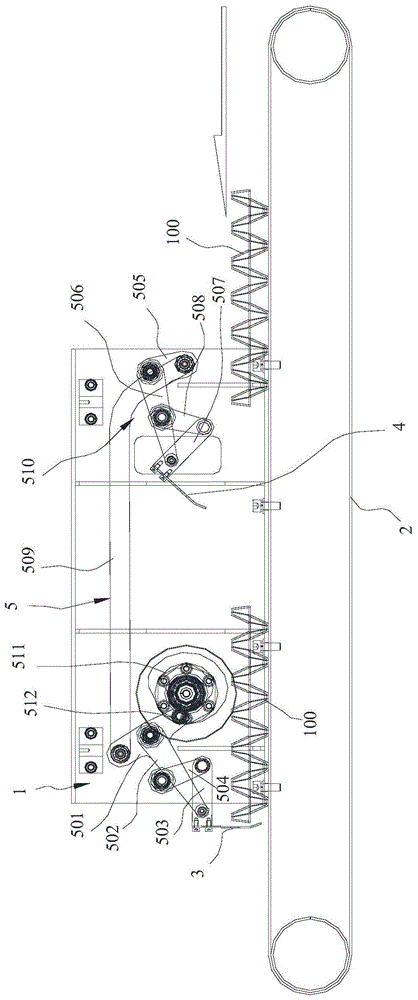

[0022] Such as Figure 1~2 The shown orderly discharging mechanism of a conveyor line includes: a frame 1, a conveyor belt 2, a front baffle 3, a rear baffle 4 and a driving mechanism 5, wherein the conveyor belt 2 is installed on the frame 1, For conveying the product 100, the conveyor belt 2 has an outlet end 21 located at the front end of the conveying direction and an inlet end 22 located at the rear end of the conveying direction; a front baffle 3, located at the outlet end 21, is used to block the product 100; a rear baffle 4, located at the inlet end 22, used to block the product 100; the driving mechanism 5, drivingly connected with the front baffle 3 and the rear baffle 4 respectively, and the driving mechanism 5 is used to drive the front baffle 3 near the outlet 21 and switch between positions away from the outlet port 21, and drive the tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com