Heat-shrinkable tube guide packaging machine

A heat-shrinkable tube and packaging machine technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin-material processing, etc., can solve the problems of no guide device and easy damage to the surface of the heat-shrinkable tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

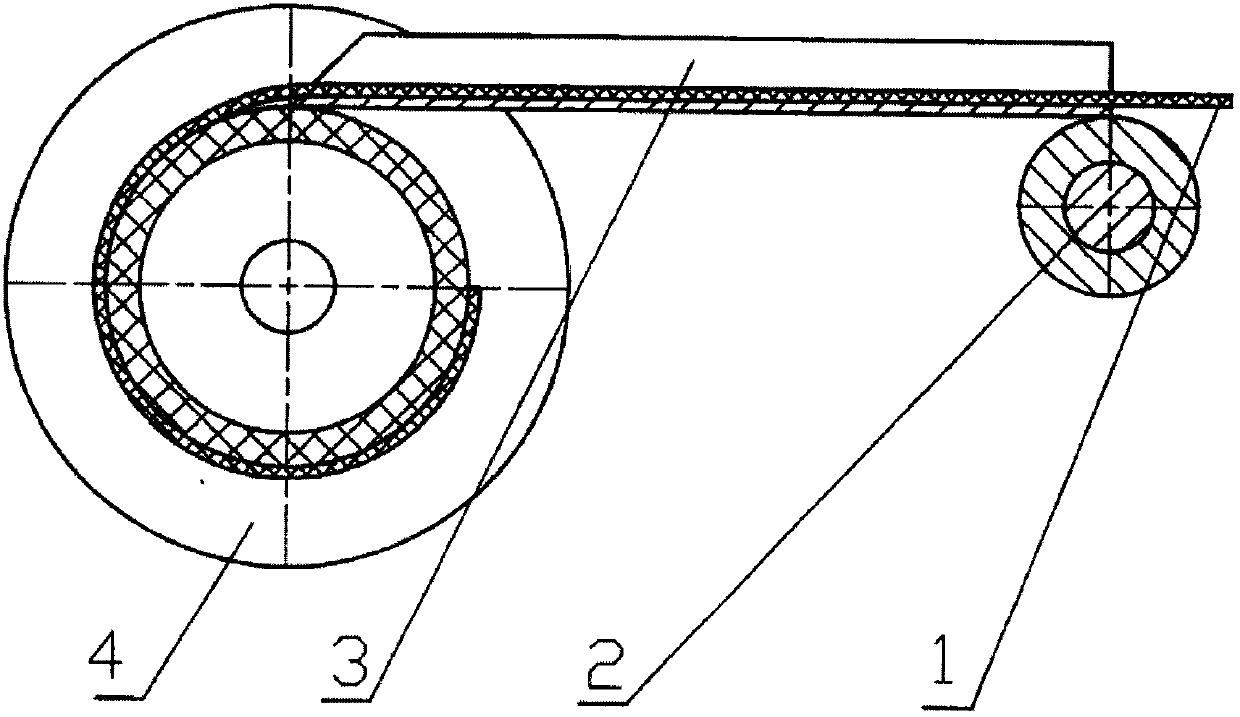

[0010] exist figure 1 Among them, the guide groove (3) is made of stainless steel, and rotates around the rotating shaft (2) through the sliding bearing, the guide groove (<3) extends into the packaging tray (4), and the heat shrinkable tube (1) is inserted into the guide groove (3) ) after being guided by the guide groove (3), it is packaged on the packaging tray (4).

[0011] The surface of the heat-shrinkable tubes packaged by the heat-shrinkable tube-guiding packaging machine will not be damaged. No matter how skilled the operator is, the heat-shrinkable tubes on the packaging tray are very neat and smooth after packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com