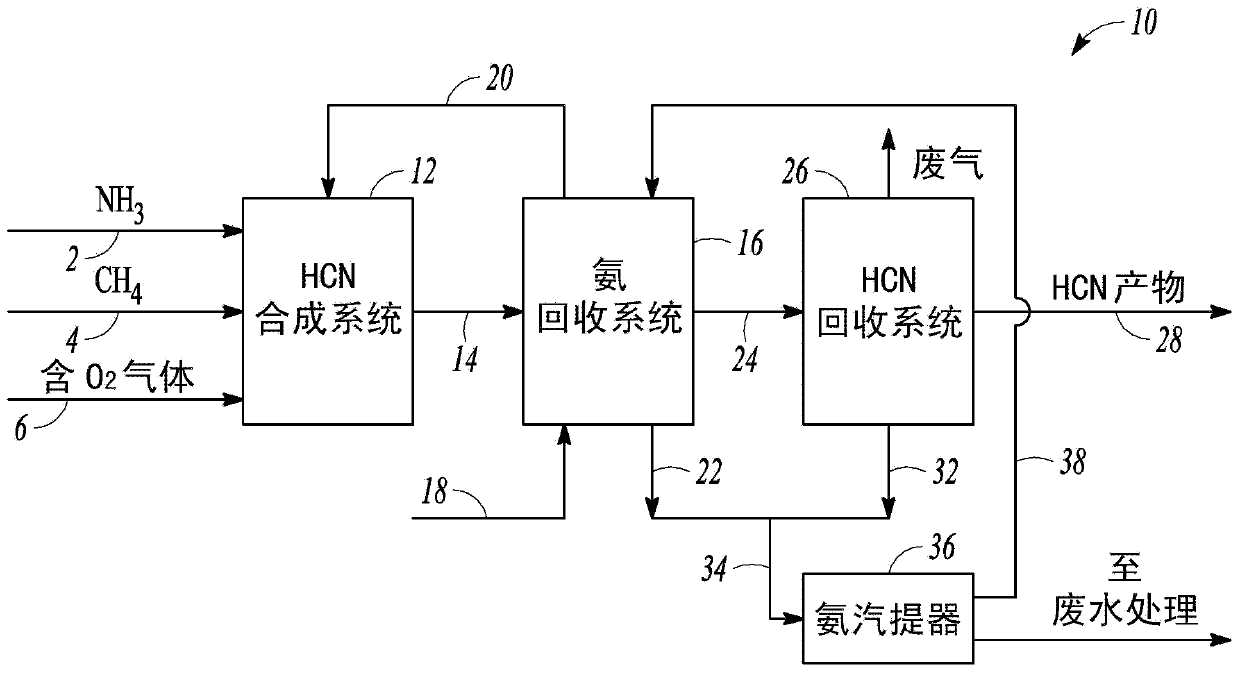

Reactor Scheme in the Andrussow Process

A technology of reactor and main reactor, applied in the reaction of gas and gas under catalytic active body, chemical instrument and method, preparation/purification/separation of hydrogen cyanide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The present disclosure may be better understood by reference to the following examples, which are provided by way of example. The present disclosure is not limited to the examples given herein.

Embodiment 2

[0071] Example 2 - Supplementary Reactor Replaces Suboptimal Primary Reactor

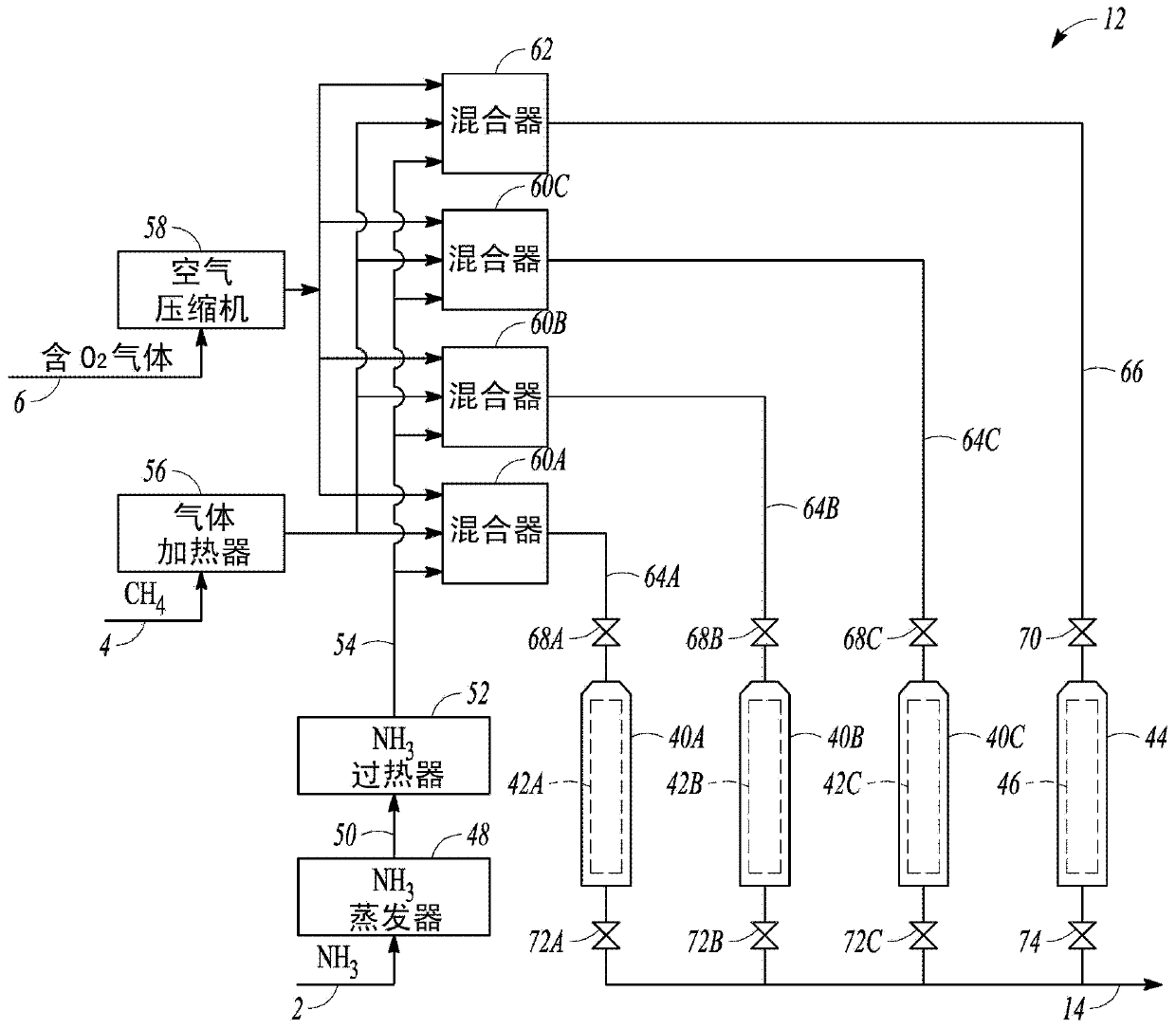

[0072] A 4 inch inner diameter stainless steel reactor with a ceramic insulating liner inside was used for the pilot test. Forty sheets of 90wt%Pt / 10wt%Rh 40 mesh gauze from Johnson Matthey (USA) were loaded as catalyst beds. A perforated alumina sheet was used for the catalyst sheet support. Set the total flow rate at 2532 SCFH (standard cubic feet per hour). In the production sequence, hydrogen cyanide was produced from three main reactors similar in configuration to that described in Comparative Example 1. The apparatus of Example 2 also included a supplementary reactor. The performance of the main reactor was monitored by determining the overall yield of hydrogen cyanide. The lower limit of the optimal yield in this example is based on NH 3 3% lower than usual. One of the three main reactors was detected to have a suboptimal gaseous product stream containing greater than 0.6 mol% unreacted...

Embodiment 3

[0075] Example 3 - Supplementary Reactor Running Simultaneously with Suboptimal Primary Reactor

[0076] A 4 inch inner diameter stainless steel reactor with a ceramic insulating liner inside was used for the pilot test. Forty sheets of 90wt%Pt / 10wt%Rh 40 mesh gauze from Johnson Matthey (USA) were loaded as catalyst beds. A perforated alumina sheet was used for the catalyst sheet support. Set the total flow rate at 2532 SCFH (standard cubic feet per hour). In the production sequence, the hydrogen cyanide production plant consists of three main reactors and one supplementary reactor, similar to the configuration described in Example 2. The performance of the main reactor was monitored by determining the overall yield of hydrogen cyanide. The lower limit of the optimal yield in this example is based on NH 3 3% lower than normal. One of the three main reactors was detected to have a suboptimal gaseous product stream containing greater than 0.6 mol% unreacted methane. A subo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com