Coal mine large-mining-depth and next-group coal exploitation water control comprehensive treatment method

A comprehensive management and large mining depth technology, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve problems such as difficult control, safety threats to underground drilling construction, low production efficiency, etc. Social benefits, the effect of preventing mine water inrush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

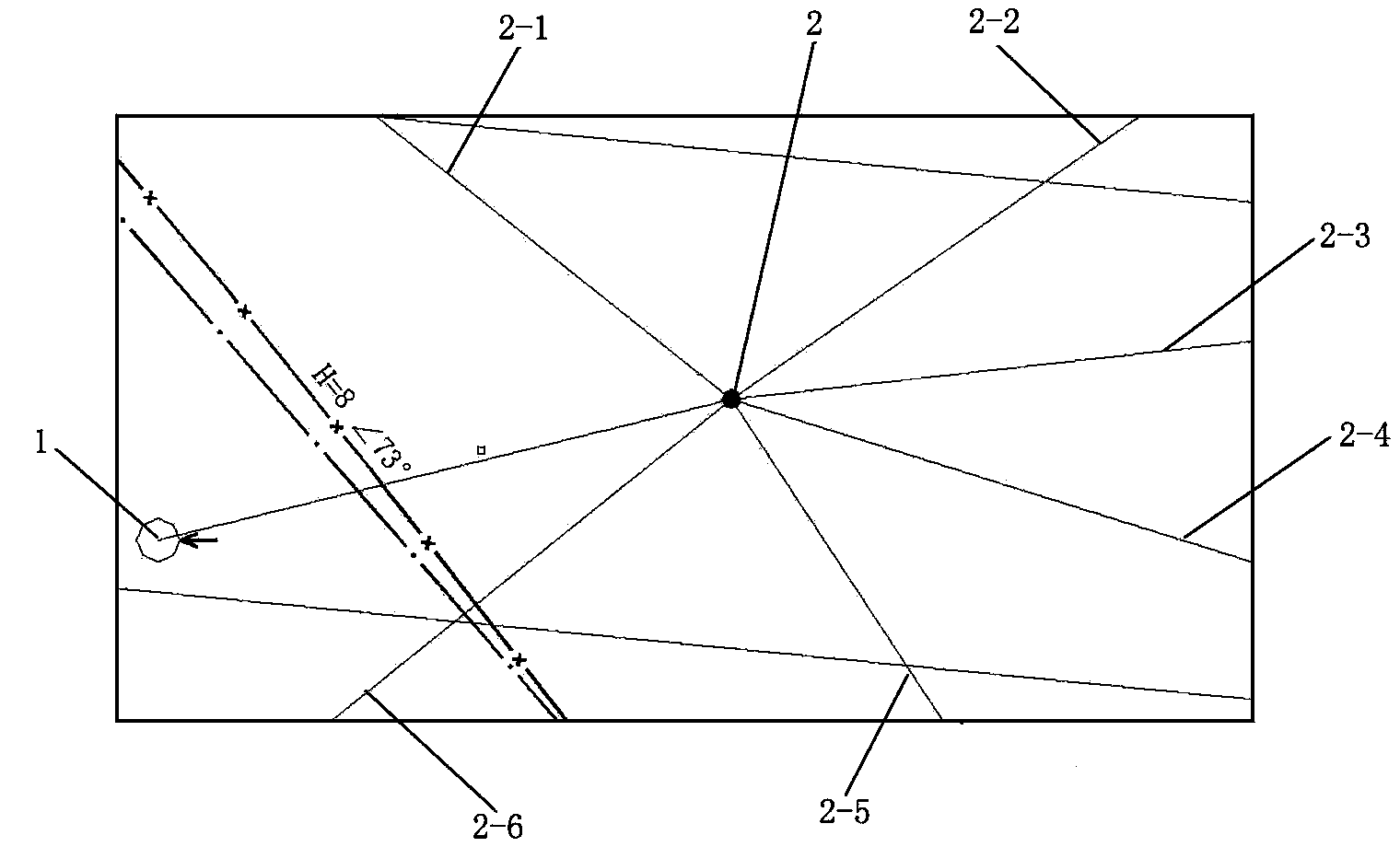

[0054] Embodiment 1 (the present invention is applied in Handan and Xingtai mining area):

[0055] In the Hanxing mining area, there have been 10 water inrushes under pressure on the floor since more than 10 years. Since the No. 4 Yeqing coal seam was mined in October 1998 in a certain mine, water inrush occurred in all 4 Yeqing working faces, especially in the goaf of the 15423N working face which was used as a protective layer on January 8, 2009. Water inrush is the most serious, and the amount of water inrush exceeds the maximum drainage capacity of the mine, and the mine is forced to stop production. According to the hydrological observation data and water quality monitoring data, it is determined that the source of water inrush is Austrian ash water, and the water inrush channel is a hidden water-guiding subsidence column, which fully demonstrates the importance of preventing highly confined Austrian ash aquifer on the coal seam floor. The mining depth has reached more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com