Testing system for hydraulic ram

A technology for testing systems and hydraulic cylinders, which is applied in fluid pressure actuation system testing, fluid pressure actuating devices, mechanical equipment, etc., and can solve problems such as inconvenience and low efficiency of hydraulic cylinder testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

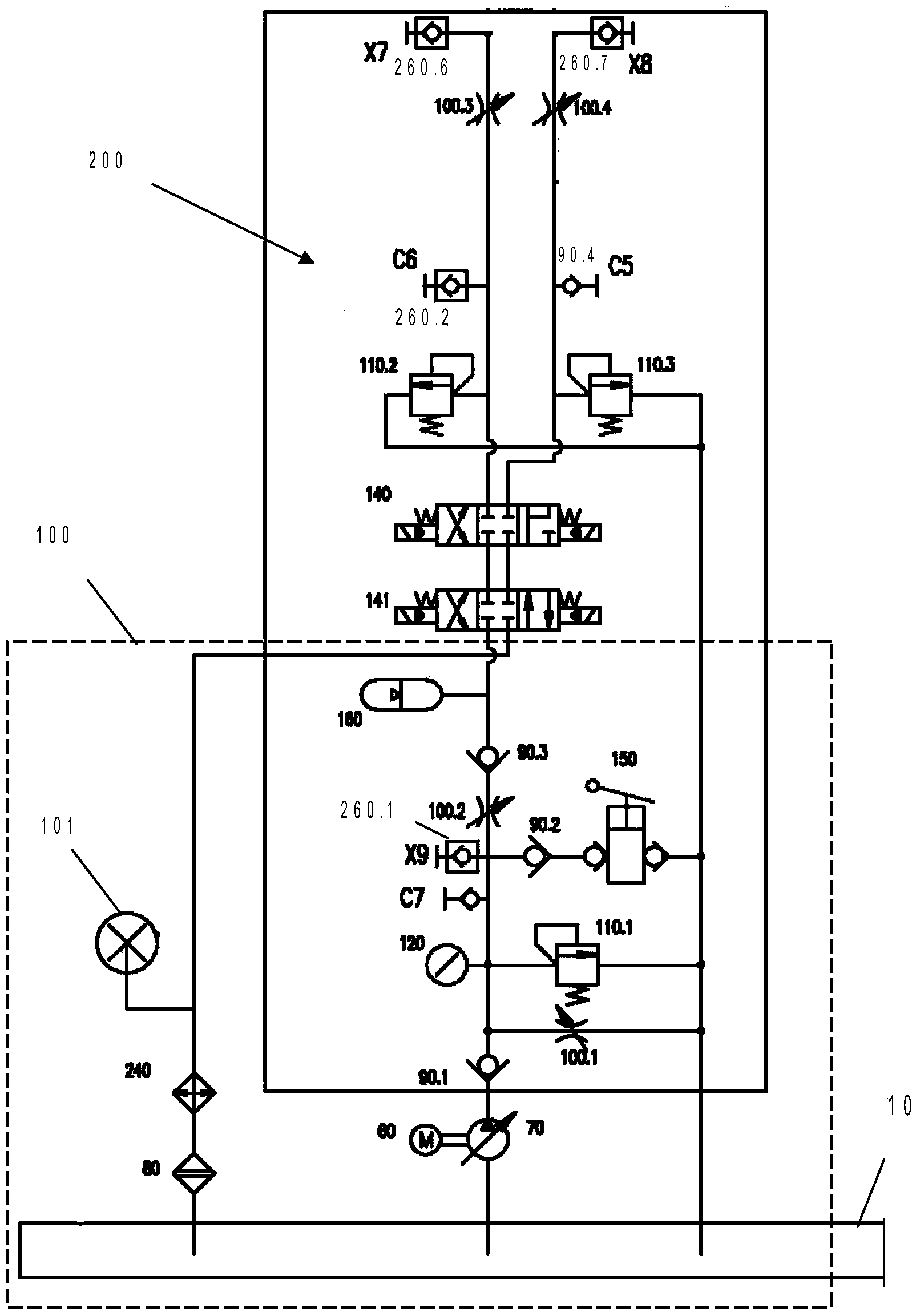

[0018] like figure 1 As shown, the hydraulic cylinder testing system of the present invention includes a hydraulic power source 100 and a main testing unit 200 .

[0019] Wherein, the main test unit 200 includes a first, three-position, four-way electromagnetic reversing valve 141, a second three-position, four-way electromagnetic reversing valve 140, a second relief valve 110.2, a third relief valve 110.3, a third throttle valve 100.3, and a fourth throttle valve 100.4.

[0020] The c oil port of the first three-position four-way electromagnetic reversing valve 141 is connected to the a oil port of the second three-position four-way electromagnetic reversing valve 140, and the c oil port of the second three-position four-way electromagnetic reversing valve 140 is connected to the second The inlet of the overflow valve 110.2, the second hydraulic control check valve 260.2 and the third throttle valve 100.3, the second hydraulic control check valve 260.2 is connected to the C6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com