Main feed water bypass regulating valve

A bypass regulating valve, main water supply technology, applied in valve device, valve details, sliding valve and other directions, can solve the problems of poor connection stability, easy failure of the connection between the valve stem and the valve core, etc., to extend the service life, protect The function of normal use and the effect of avoiding the vibration of the valve core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

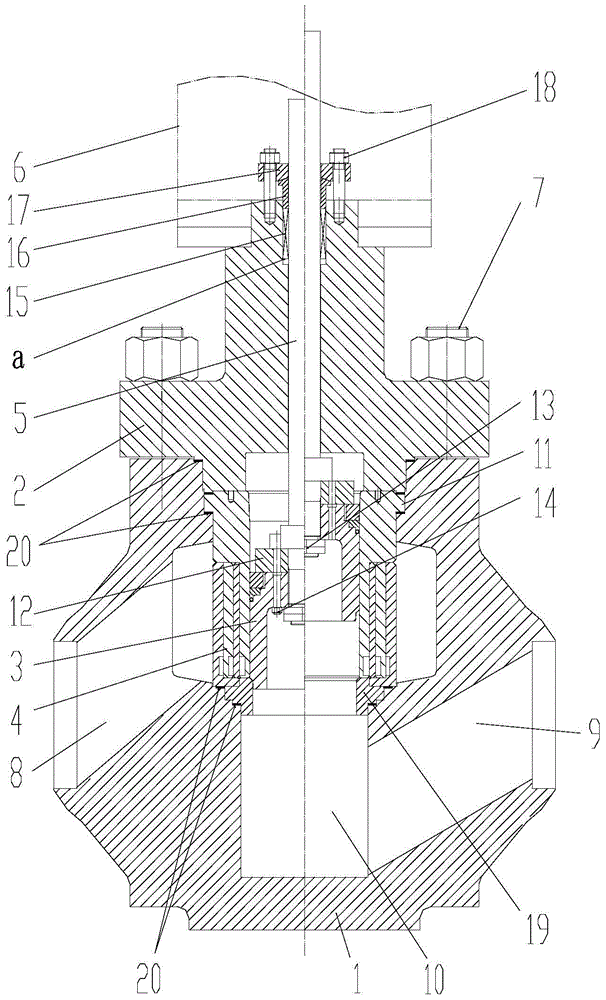

[0023] figure 1 It is a structural schematic diagram of the main feedwater bypass regulating valve of the preferred embodiment of the present invention. Such as figure 1 As shown, the main feedwater bypass regulating valve in this embodiment includes a valve body 1, a valve cover 2, a valve core 3, a valve cage 4, a valve stem 5 and an actuator 6, and the valve body 1 is provided with an inlet channel 8 and an outlet channel 9 and the transfer channel 10 for connecting the inlet channel 8 and the outlet channel 9, the valve core 3 is set in the transfer channel 10, the valve cage 4 is set outside the valve core 3, and the valve cage 4 is sealed in the transfer channel 10 At the part intersecting with the inlet passage 8, the seepage hole of the cage 4 is opened on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com