A comprehensive measuring device for deformation of rotating arm of parallel double-joint coordinate measuring machine

A technology of a coordinate measuring machine and a rotating arm, which is applied in the direction of measuring devices, optical devices, instruments, etc., to achieve the effect of compact device structure and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

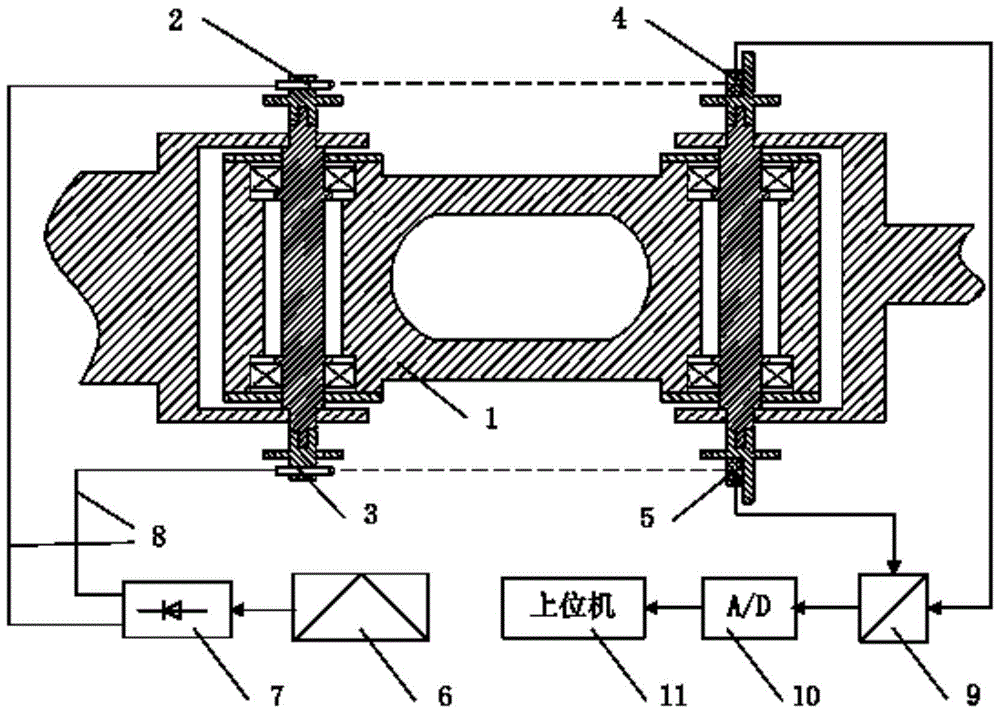

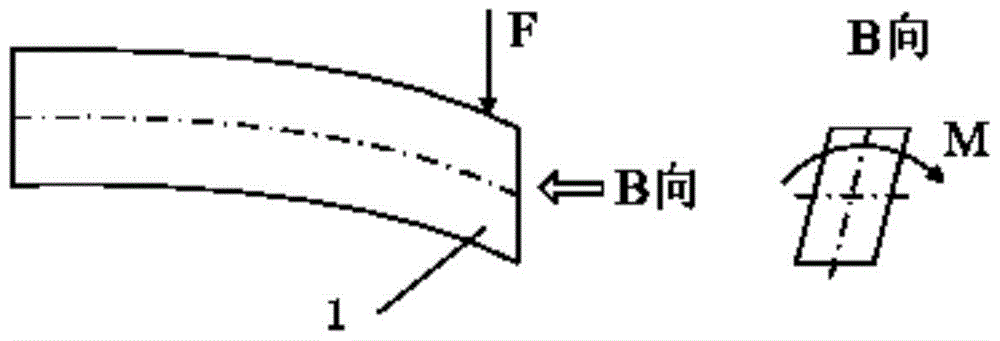

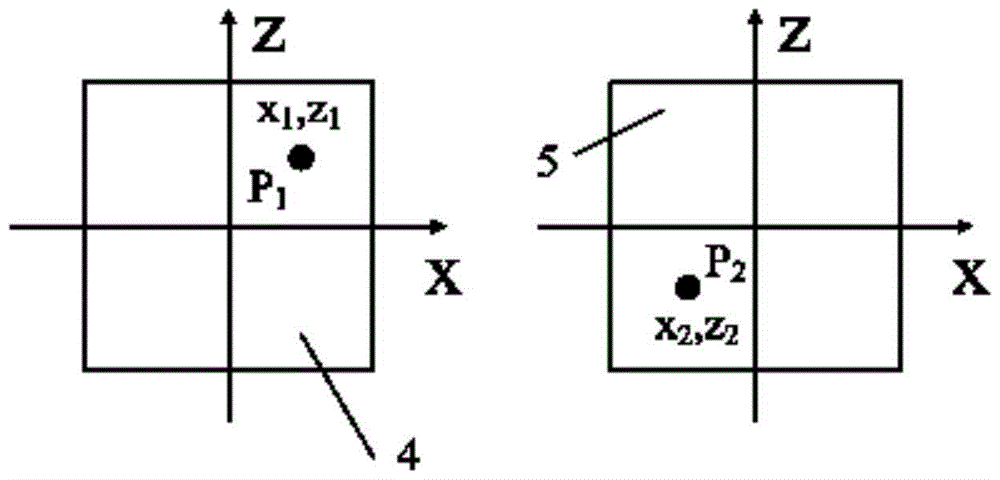

[0019] Such as figure 1 shown. A comprehensive measurement device for the deformation of a rotating arm of a parallel double-joint coordinate measuring machine, comprising a rotating arm 1, an upper optical self-collimation lens 2 is installed on the top of the left end of the rotating arm 1, a lower optical self-collimation lens 3 is installed on the bottom of the left end, and the rotating arm 1 The upper optical position sensitive detector 4 is installed on the top of the right end, the lower optical position sensitive detector 5 is installed on the bottom of the right end, the upper optical self-collimating lens 2 corresponds to the position of the upper optical position sensitive detector 4 and is on the same horizontal line, The self-collimating lens 3 corresponds to the position of the lower optical position sensitive detector 5 and is on the same horizontal line, and also includes a laser diode drive circuit 6, a laser diode 7, a current / voltage conversion circuit 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com