A special high-voltage power cable for submarine

A high-voltage power and cable technology, applied in the field of power cables, can solve problems such as increased cable weight and cost, short service life, and increased conductive cable cores, to reduce manufacturing costs and laying costs, with small skin effect coefficients and improved durability. The effect of corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

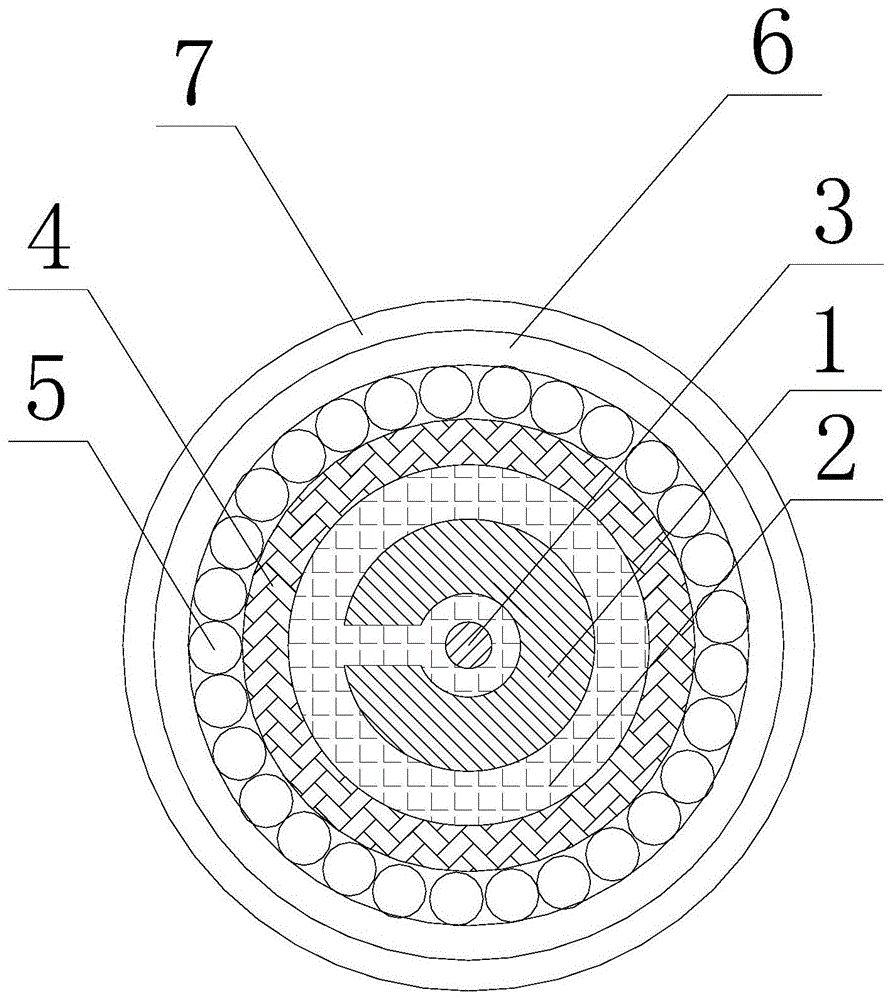

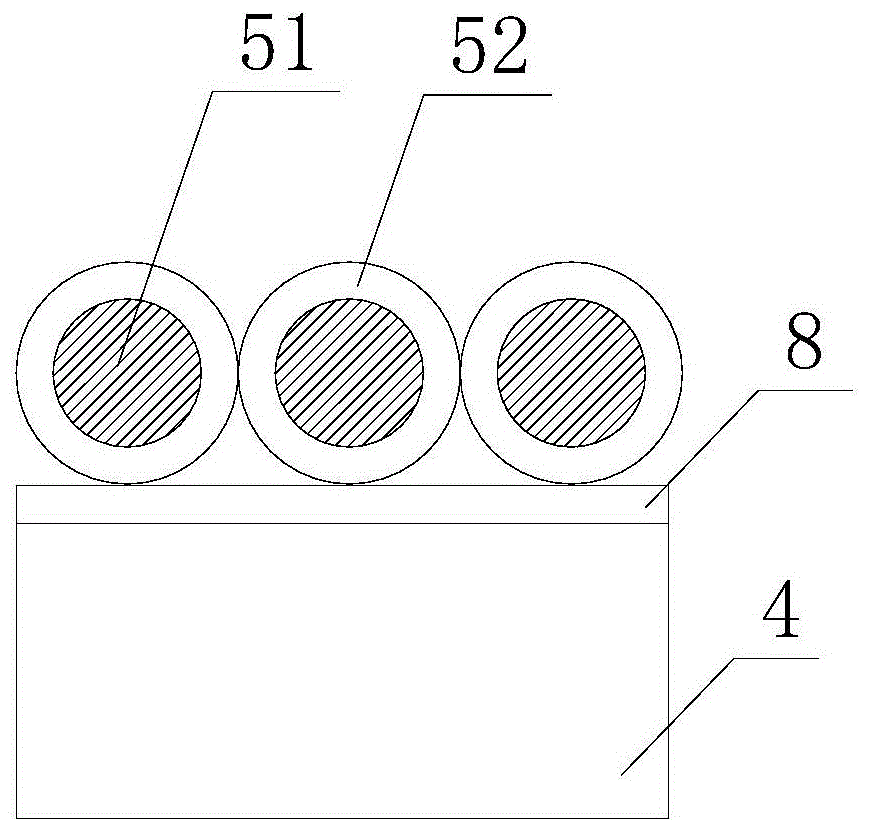

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a special submarine high-voltage power cable proposed by the present invention; figure 2 for figure 1 A partial schematic diagram of the shielding structure of a medium power cable.

[0013] refer to figure 1 and combine figure 2 , a special submarine high-voltage power cable proposed by the present invention is used for power transmission on the seabed, including a power transmission conductor and a communication optical fiber. The radius of the inner ring is equal, the communication optical fiber is located in the power transmission conductor ring and coaxially arranged with the inner ring of the power transmission conductor, the power transmission conductor and the communication optical fiber are wrapped by insulating materials to form a whole with a circular cross section, and the outer circumference of the insulating material is aluminum The cladding layer formed by wrapping the plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com