Circuit board assembly method and circuit board

An assembly method and circuit board technology, which are applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, etc., can solve product defects, improve the installation complexity of plug-in devices, and are not easy to control the operation accuracy. and other problems to achieve the effect of saving production costs and ensuring support accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to solve the above problems, the present invention provides a method for assembling a circuit board and a circuit board.

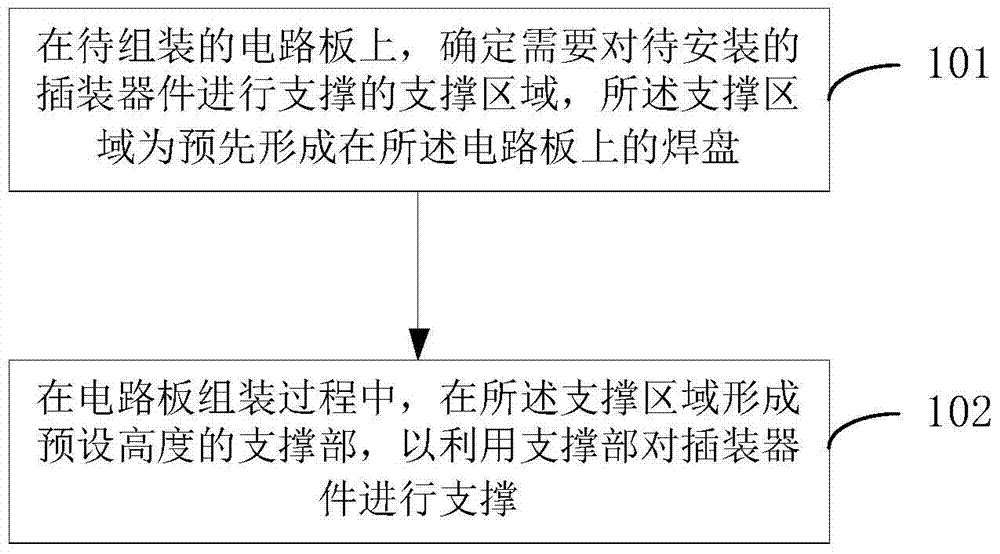

[0036] See figure 1 , a flowchart of a circuit board assembly method, comprising the steps of:

[0037] 101. On the circuit board to be assembled, determine the support area that needs to support the plug-in device to be installed;

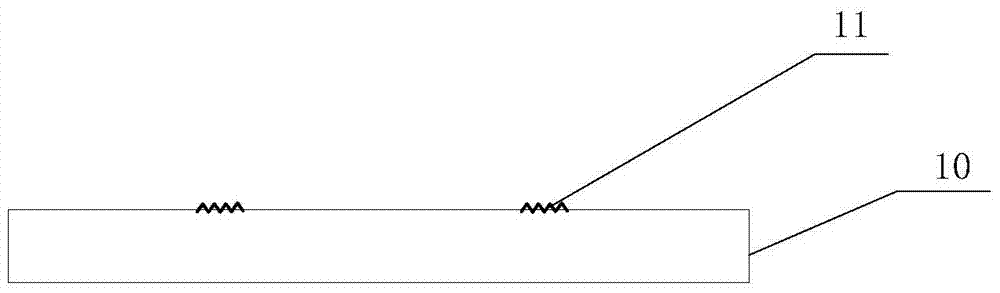

[0038] like Figure 2-1 As shown, on the circuit board 10 to be assembled, according to parameters such as the installation position of the plug-in device to be installed, the model size and the surrounding structural layout, the support area 11 can be preset on the circuit board 10 to be assembled, and the support area 11 It is the area marked with a black broken line on the upper surface of the circuit board 10 (the broken line in the figure is only a mark and does not represent a structure). Among them, in the circuit board manufacturing process, the pads used as the support area can be pre-set in advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com