A high-efficiency multi-bladed propeller propulsion system for an airship

A propulsion system and propeller technology, applied in the direction of rigid airships, etc., can solve the problems of limited airship resistance contribution, increase airship surface pressure resistance, hull resistance increase, etc., achieve good support and connection installation reference function, large pulling force, delay The effect of air separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

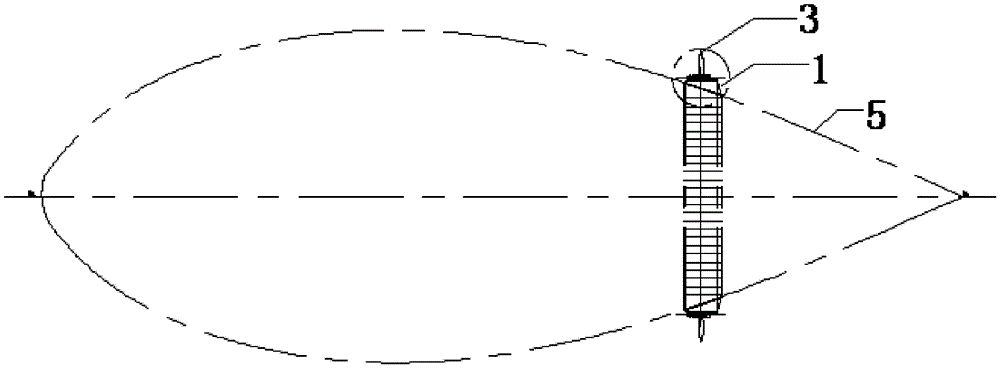

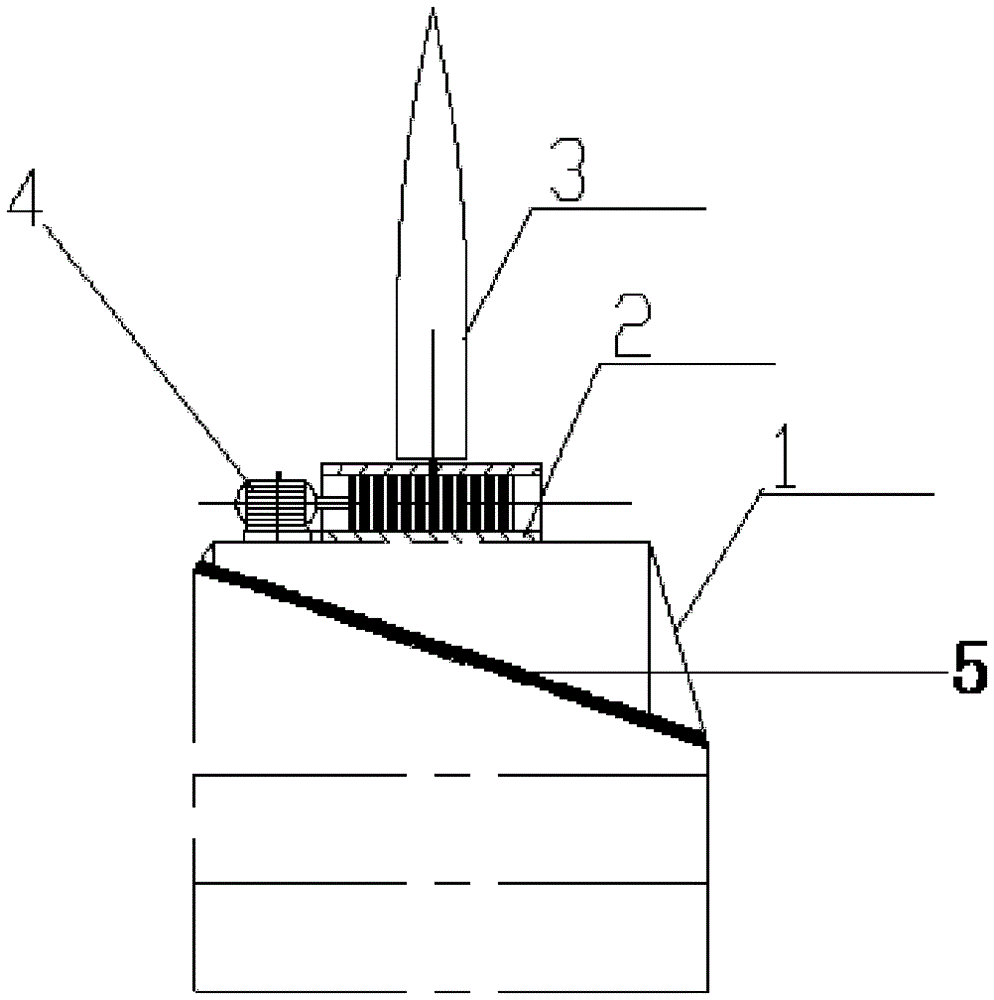

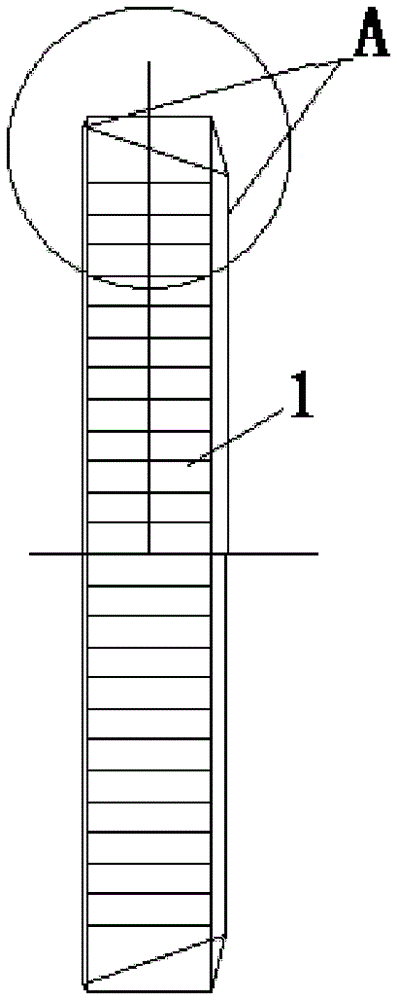

[0030] Such as figure 1 , figure 2 As shown, the high-efficiency multi-blade propulsion system for an airship according to the present invention includes an annular truss 1, a bearing 2, several blades 3 and a motor 4; On the airship outer skin 5 of the cross-section; as image 3 , Figure 4 and Figure 5 As shown, the ring truss 1 is a concentric ring frame with two inner and outer layers, its section is trapezoidal, and its inner side is an inclined side; as Figure 6 As shown, the bearing 2 includes an inner ring 201, several rolling rotors 202 and an outer ring 203, the surfaces of the inner ring 201 and the outer ring 203 are provided with smooth raceways, and the outer surface of the outer ring 203 is evenly opened with several round holes, The inner ring 201 is connected and fixed to the outer side of the ring truss 1, with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com