Peristaltic pump

A peristaltic pump and pump head technology, applied in the direction of pumps, pump components, pump control, etc., can solve the problems of complex leak detectors, expensive pump head replacement, excessive fluid accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

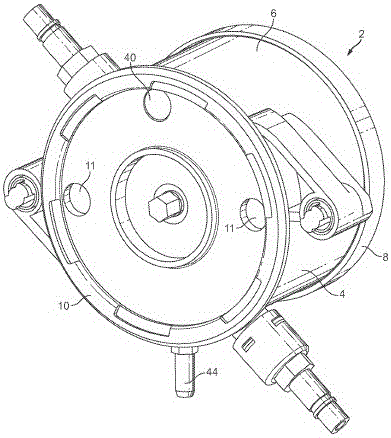

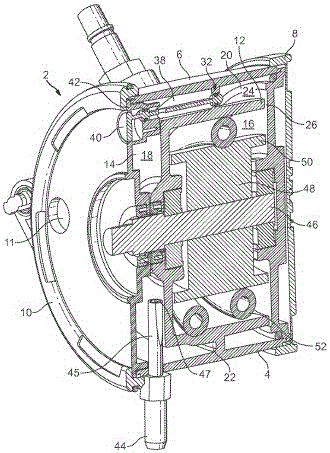

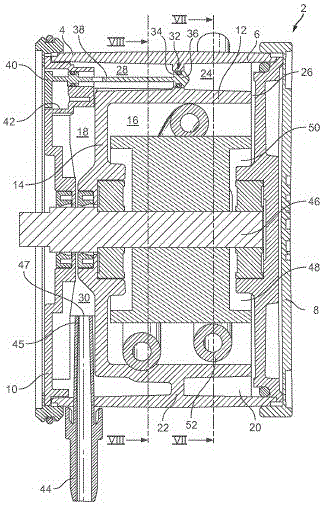

[0025] figure 1 with figure 2 A pump head 2 for use in a peristaltic pump is shown. The pump head 2 comprises a housing 4 having a substantially cylindrical outer wall 6 closed at opposite ends by end caps 8, 10, wherein any or all of the end caps 8, 10 may be provided by suitable Made of thermoplastic material. The outer wall 6 and / or one or both end caps can be made by moulding. The end caps 8 , 10 may be spin welded or ultrasonically riveted to the outer wall 6 to form the sealed housing 4 . The cylindrical outer wall 6 of the housing 4 defines the pump head axis. The end cover 10 includes a positioning recess 11, the drive unit 1 (in Image 6 (shown in the middle part) is positioned in the recess 11 to ensure that the pump head 2 is arranged relative to the drive unit 1 in one of a plurality of predetermined directions.

[0026] Such as figure 2 As shown, the housing 4 is divided into a pumping chamber 16 and an auxiliary chamber 18 by a substantially cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com