Integral type dedusting-deodorizing device in unloading hall of rubbish treatment station, and work flow of dedusting-deodorizing device

A garbage treatment station, integrated technology, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high equipment cost, large pipeline pressure loss, large floor area, etc., and achieve high dust removal efficiency , low pressure loss and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

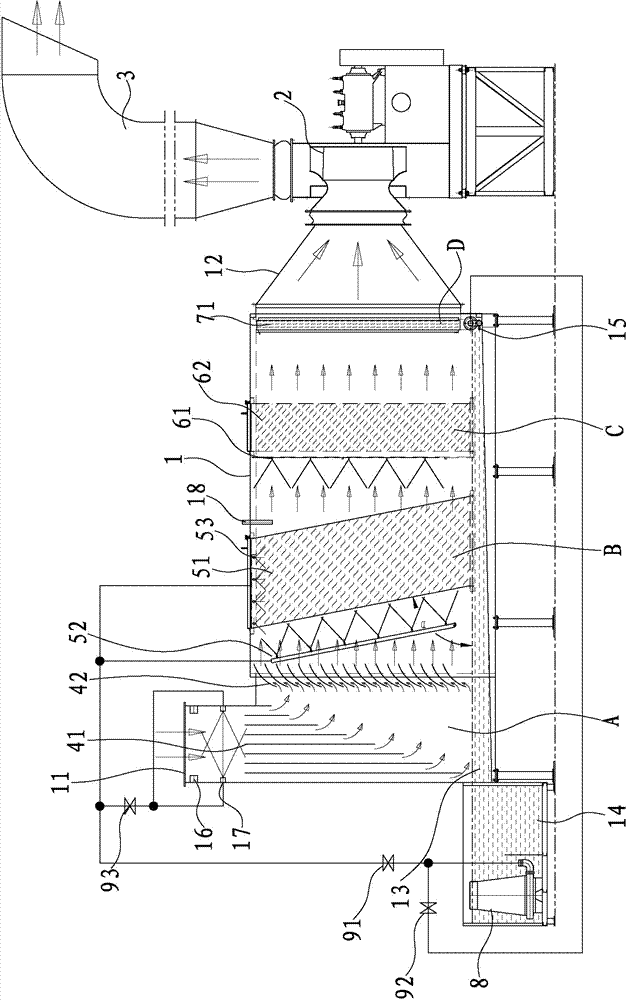

[0030] What the present invention discloses is an integrated dust removal and deodorization device used in the unloading hall of the garbage disposal station, such as figure 1 , 2 Shown is the preferred embodiment of the present invention. The dust removal and deodorization device includes a box body 1, one side of the box body 1 is provided with an air inlet 11 with an opening vertically upward, and the other side is provided with an air outlet 12 with an opening in a horizontal direction. There are dust separation area A, filler washing area B, deodorization area C, and water mist removal area D four-stage gas purification area in sequence from the air inlet 11 to the air outlet 12. The air outlet 12 is provided with a fan 2. The outlet end of the fan 2 is connected with an exhaust pipe 3 . in:

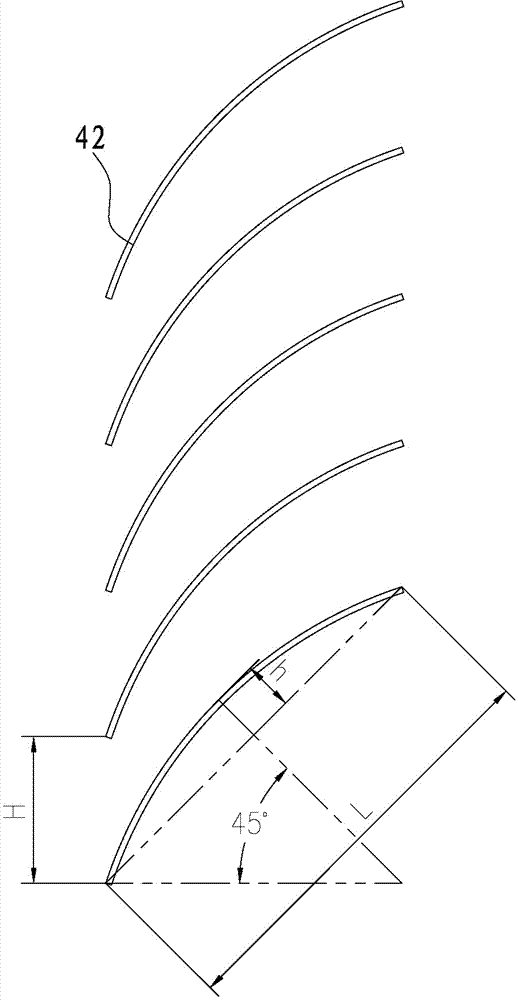

[0031] The dust separation area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap