Instant modified cellulose cross-linked clean fracturing fluid and preparation method thereof

A technology for cleaning fracturing fluid and cellulose, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of unconventional oil and gas reservoirs that are difficult to meet large-scale fracturing and instant dissolution, require large cycle power, and various types of additive materials and other problems, to achieve a good effect of inhibiting the hydration expansion ability of clay, avoiding poor viscosity, and good placement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

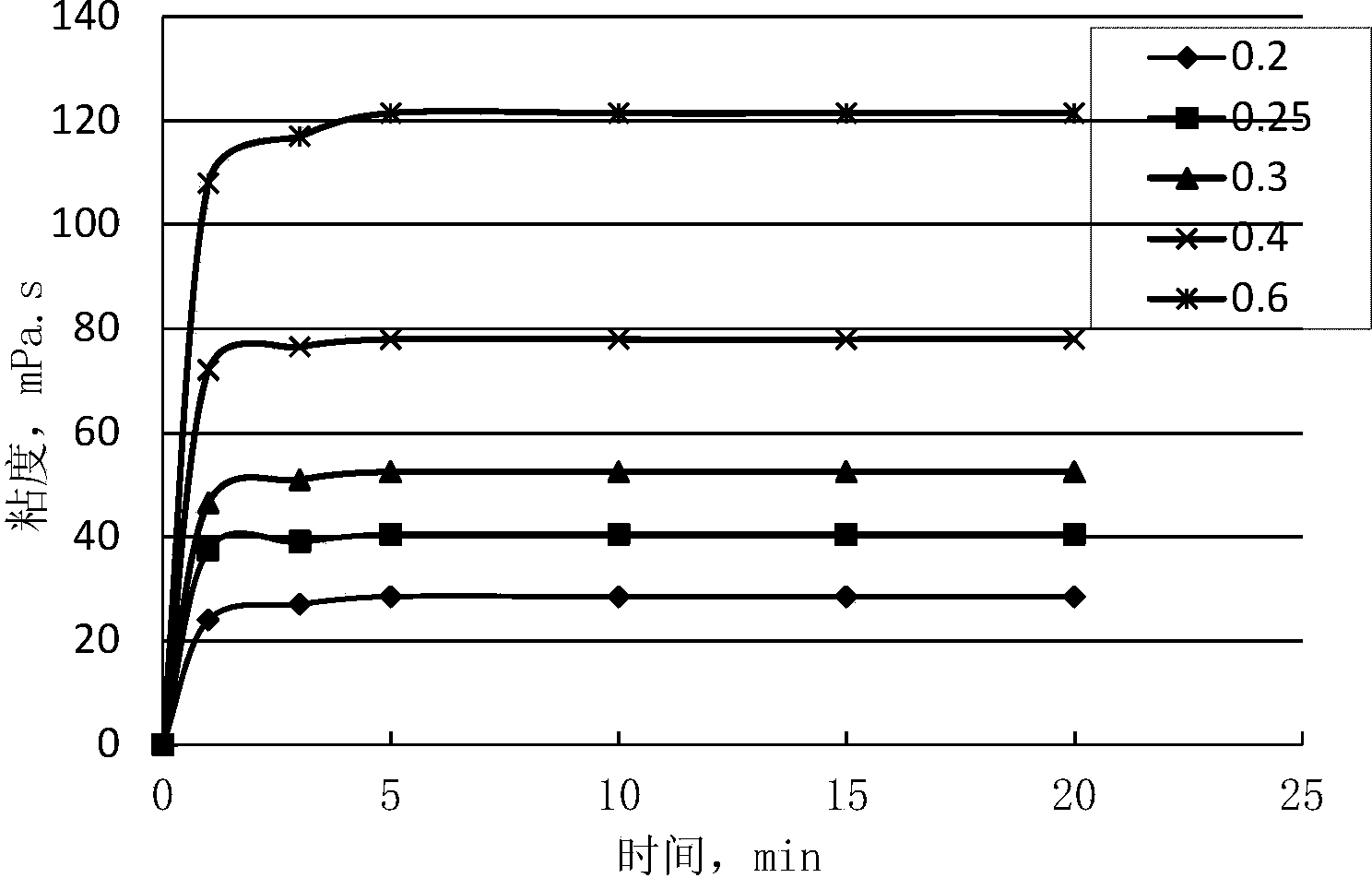

Embodiment 1

[0029] This embodiment provides an instant modified cellulose cross-linked cleaning fracturing fluid, which is composed of the following components:

[0030] FAG-500 type modified cellulose, 0.2 parts by weight; FAZ-1 type thickening initiator, 0.15 parts by weight; DL-16 type drainage aid, 0.3 parts by weight; FAJ-305 type crosslinking regulator, 1.0 parts by weight ; FAC-201 type polar chelating organic zirconium crosslinking agent, 0.35 parts by weight; NBA-102 type capsule gel breaker, 0.007 parts by weight; water, 100 parts by weight.

[0031] The instant modified cellulose cross-linked cleaning fracturing fluid is prepared according to the following steps:

[0032] Step 1: Add FAG-500 modified cellulose and FAZ-1 viscosity-increasing initiator to water in turn under stirring conditions, and then stir for 3 minutes to obtain an aqueous cellulose solution;

[0033] Step 2: Add DL-16 type drainage aid and FAJ-305 type cross-linking regulator to the above cellulose aqueous ...

Embodiment 2

[0037] This embodiment provides an instant modified cellulose cross-linked cleaning fracturing fluid, which is composed of the following components:

[0038] FAG-500 type modified cellulose, 0.25 parts by weight; FAZ-1 type thickening initiator, 0.15 parts by weight; DL-16 type drainage aid, 0.3 parts by weight; FAJ-305 type crosslinking regulator, 1.0 parts by weight ; FAC-201 type polar chelating organic zirconium crosslinking agent, 0.4 parts by weight; NBA-102 type capsule gel breaker, 0.006 parts by weight; water, 100 parts by weight.

[0039] The instant modified cellulose cross-linked cleaning fracturing fluid is prepared according to the following steps:

[0040] Step 1: Add FAG-500 modified cellulose and FAZ-1 viscosity-increasing initiator to water in turn under stirring conditions, and then stir for 3 minutes to obtain an aqueous cellulose solution;

[0041] Step 2: Add DL-16 type drainage aid and FAJ-305 type cross-linking regulator to the above cellulose aqueous ...

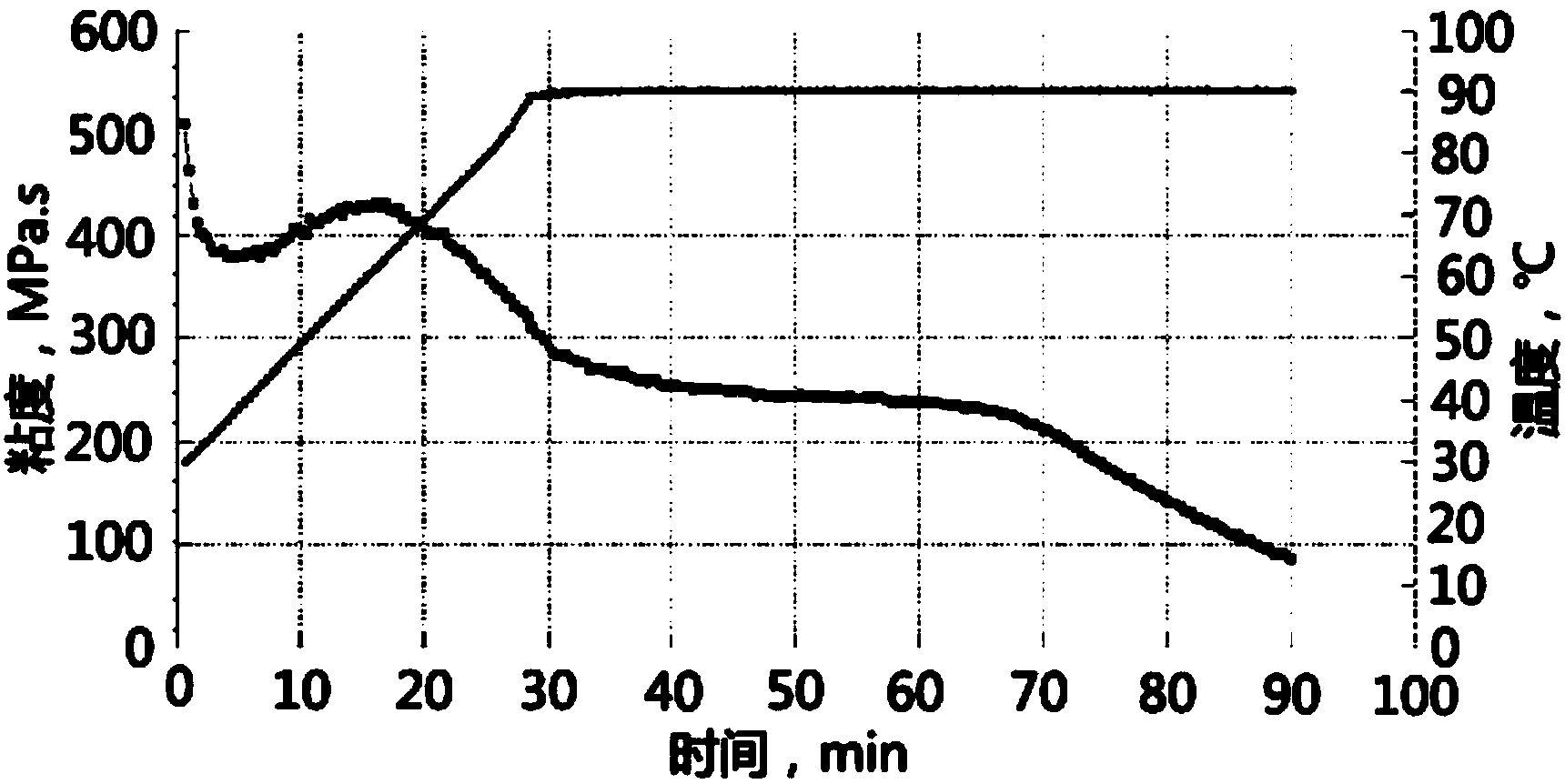

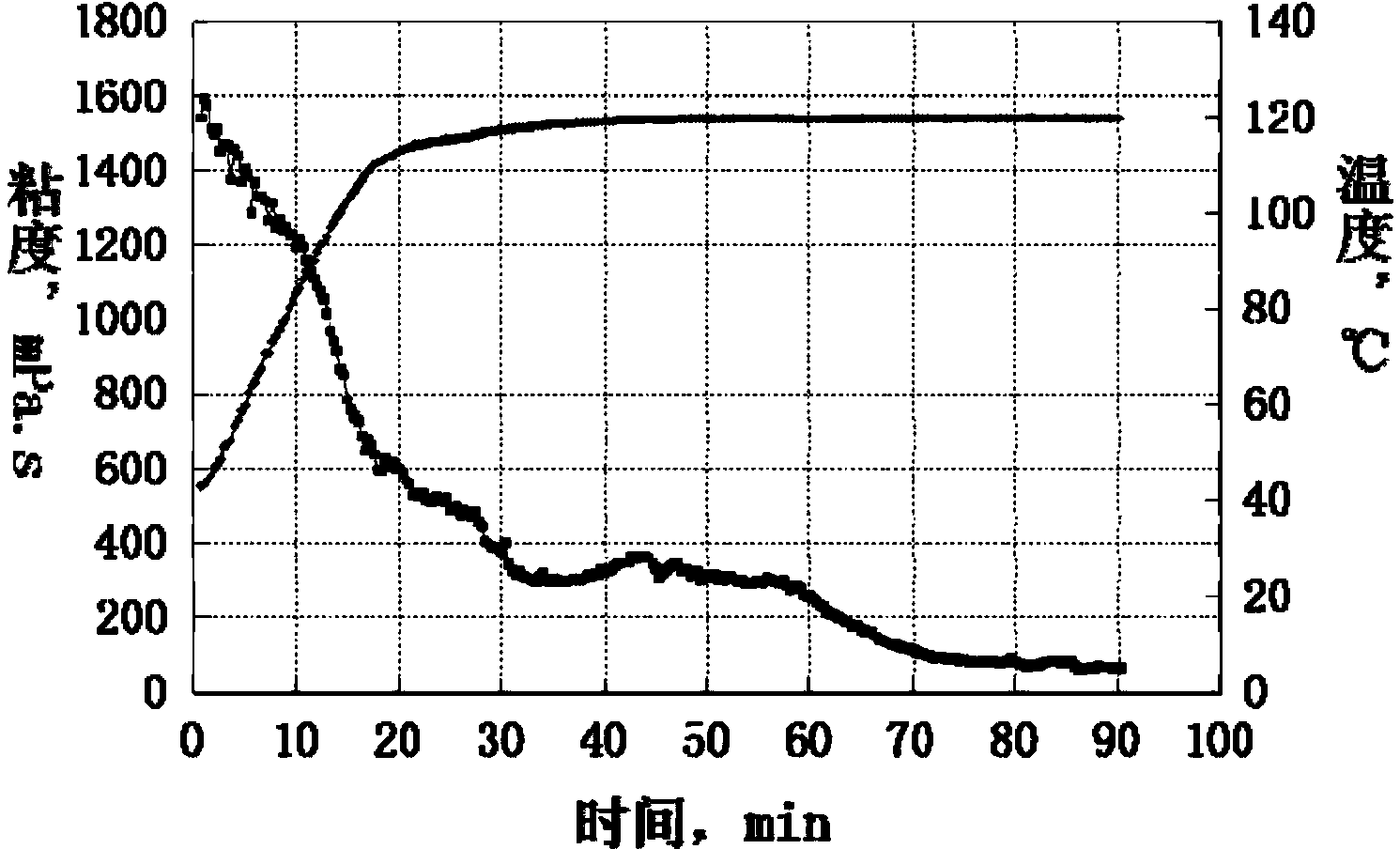

Embodiment 3

[0045] This embodiment provides an instant modified cellulose cross-linked cleaning fracturing fluid, which is composed of the following components:

[0046] FAG-500 type modified cellulose, 0.3 parts by weight; FAZ-1 type thickening initiator, 0.2 parts by weight; DL-16 type drainage aid, 0.3 parts by weight; FAJ-305 type crosslinking regulator, 1.0 parts by weight ; FAC-201 type polar chelating organic zirconium crosslinking agent, 0.5 parts by weight; NBA-102 type capsule gel breaker, 0.005 parts by weight; water, 100 parts by weight.

[0047] The instant modified cellulose cross-linked cleaning fracturing fluid is prepared according to the following steps:

[0048] Step 1: Add FAG-500 modified cellulose and FAZ-1 viscosity-increasing initiator to water in turn under stirring conditions, and then stir for 3 minutes to obtain an aqueous cellulose solution;

[0049] Step 2: Add DL-16 type drainage aid and FAJ-305 type cross-linking regulator to the above cellulose aqueous so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com