Ladle-to-ladle nodulizing method for large tonnage nodular cast iron

A nodular cast iron, large-tonnage technology, applied in the field of large-tonnage nodular cast iron upside-down spheroidization, can solve the problems of increasing spheroidizing time and increasing the risk of spheroidizing recession, achieving the effect of ensuring the quality of spheroidizing and shortening the spheroidizing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

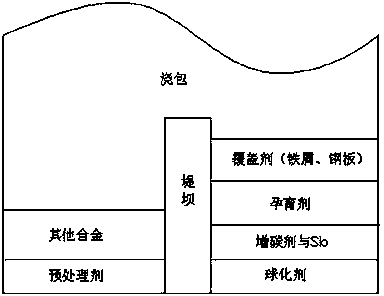

[0017] Such as figure 1 As shown, the large-tonnage nodular cast iron inversion spheroidization method, the specific steps are as follows:

[0018] ①. Melt the required iron moisture in multiple electric furnaces, raise the temperature to 1500°C, keep warm for 8 minutes, remove the slag on the surface, add 0.1% recarburizer on the surface of the molten iron, and wait for the water to come out;

[0019] ②. Add 1.4% nodulizer to one side of the dam of the nodulizer, then sprinkle 0.1% recarburizer and 0.003% Sb (antimony) on the nodulizer, and then cover the nodulizer with 0.55% BaSiFe inoculant and compact it with steel plates, and cover the corners with iron filings, then add 0.15% 390 pretreatment agent to the other side of the embankment, put it into the pit and wait for spheroidization;

[0020] ③. Now preheat the tundish A, and raise the temperature of the ladle to 400°C-500°C, then use the tundish B to discharge multiple electric furnace molten irons into the tundish A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com