Changeable air intake manifold of engine and control method thereof

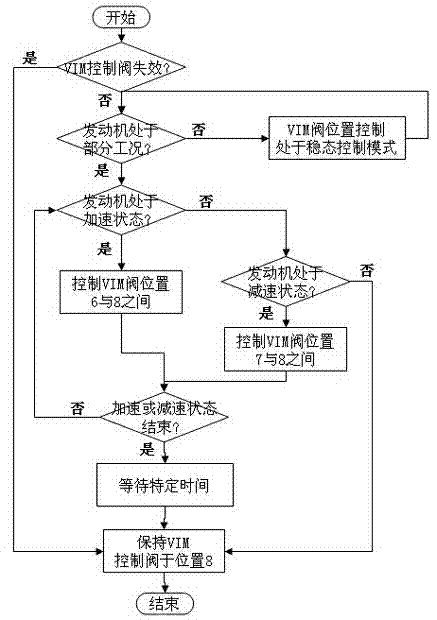

An intake manifold and control method technology, applied in engine control, engine components, combustion engine and other directions, can solve the problems of complex structure, uneven power output, complicated control program design of control mechanism, etc. Transient control, the effect of improving transient response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

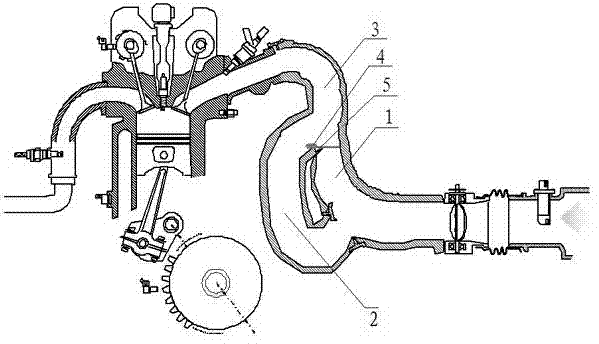

[0038] Example: see attached figure 1As shown, a variable intake manifold of an engine has a first intake passage 1 and a second intake passage 2, the length of the second intake passage 2 is greater than the length of the first intake passage 1, and the first intake passage The outlets of the first intake passage 1 and the second intake passage 2 are arranged adjacently and converge to the outlet 3 of the variable intake manifold. A valve plate 4 is hinged on the wall 5, and a valve plate driving mechanism is provided, and the valve plate driving mechanism drives the valve plate 4 to rotate according to the working conditions of the engine.

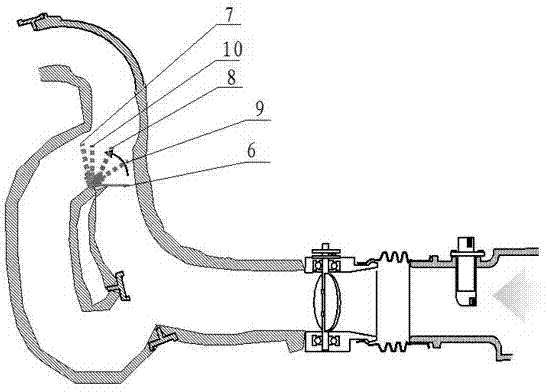

[0039] See attached figure 2 As shown, in this embodiment, the valve plate 4 has the following working positions, respectively, the first working position 6 for closing the outlet of the first air intake passage 1, and the second working position 7 for closing the outlet of the second air intake passage 2 , the third working position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com