Device for detection of perpendicularity between trailer axle and longitudinal beam and detection and locating method

A detection device and positioning method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not being able to fully guarantee the scale line, waste of manpower, error in the vertical relationship between the axle and the longitudinal beam, etc., and achieve the detection and adjustment process Clear, clear, improved precision and work efficiency, simple and convenient equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

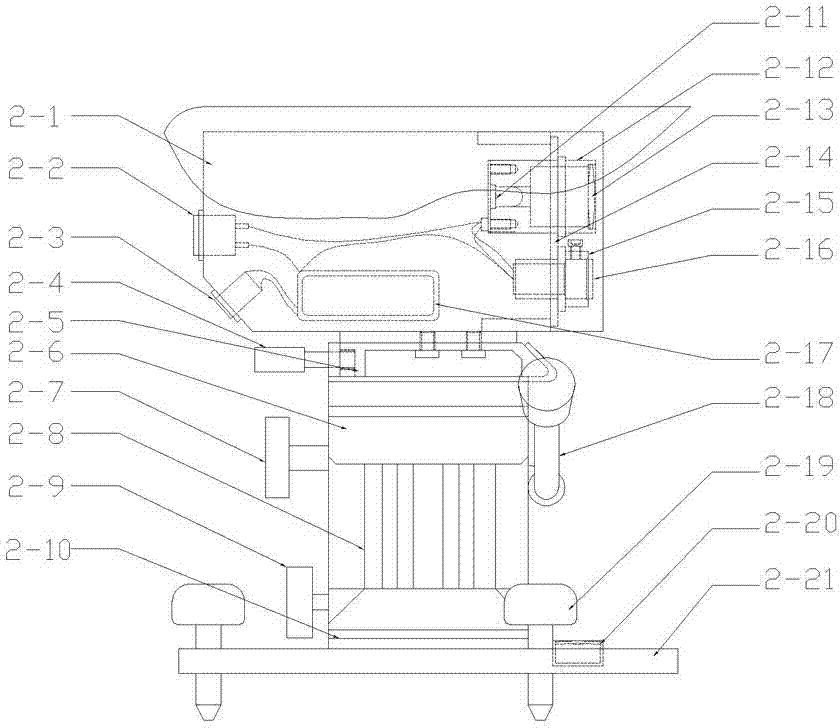

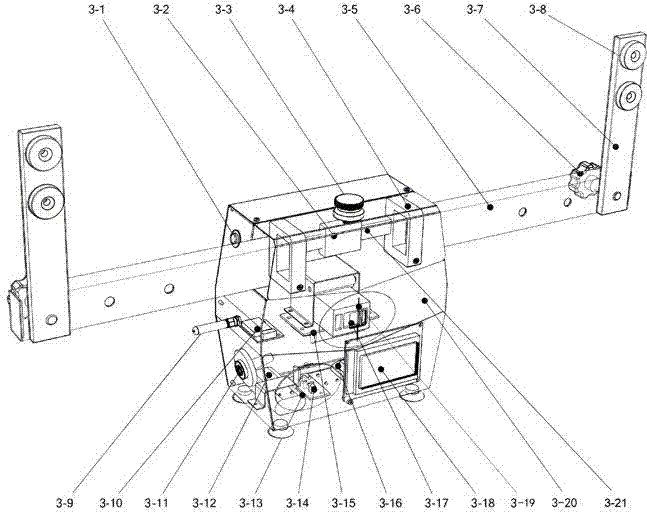

[0028] The verticality detection device between the trailer axle and the longitudinal beam of the present invention comprises a scissor centering ruler 1 for sucking and hanging onto the lower edge of the inner wall of the axle longitudinal beam 4, and a machine head for sucking and hanging on the trailer axle 5 Assembly 3, the emission assembly 2 used to emit light signals to the scissor centering ruler 1 and the nose assembly 3, such as Figure 4-6 shown. Also included are computers for receiving, storing, processing and displaying test data.

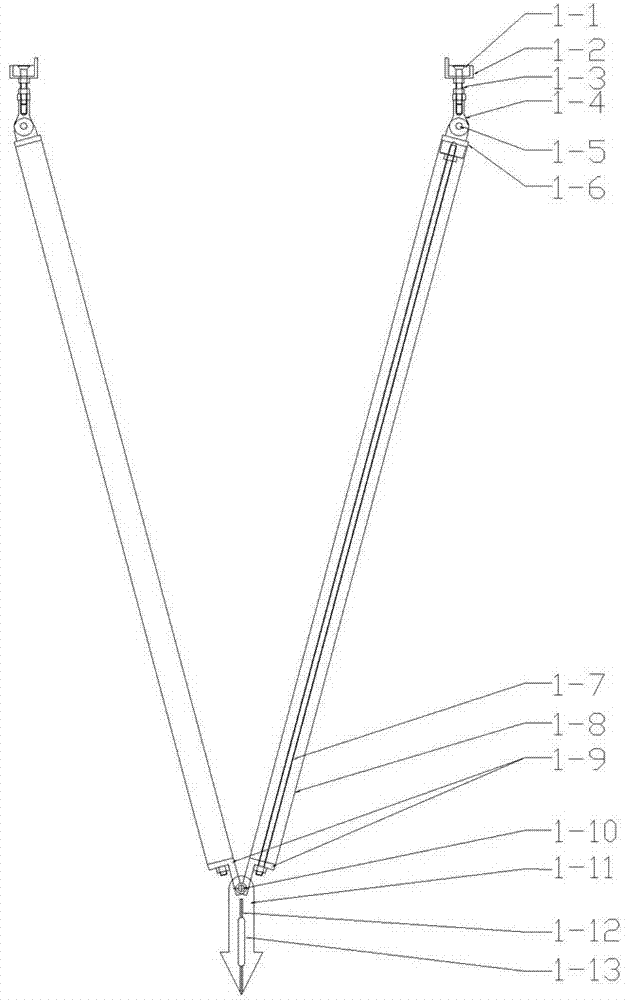

[0029] Such as figure 1 As shown, the scissor-type centering ruler 1 includes a pair of suspension rods whose lower ends are connected to the center pin shaft 1-10 and centering arrows 1-11 whose upper ends are connected to the center pin shaft 1-10. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com