Optical-coupling lens and an optical-fiber coupling connector

A fiber coupling and optical coupling technology, which is applied in the coupling of optical waveguides, etc., can solve problems such as waste and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

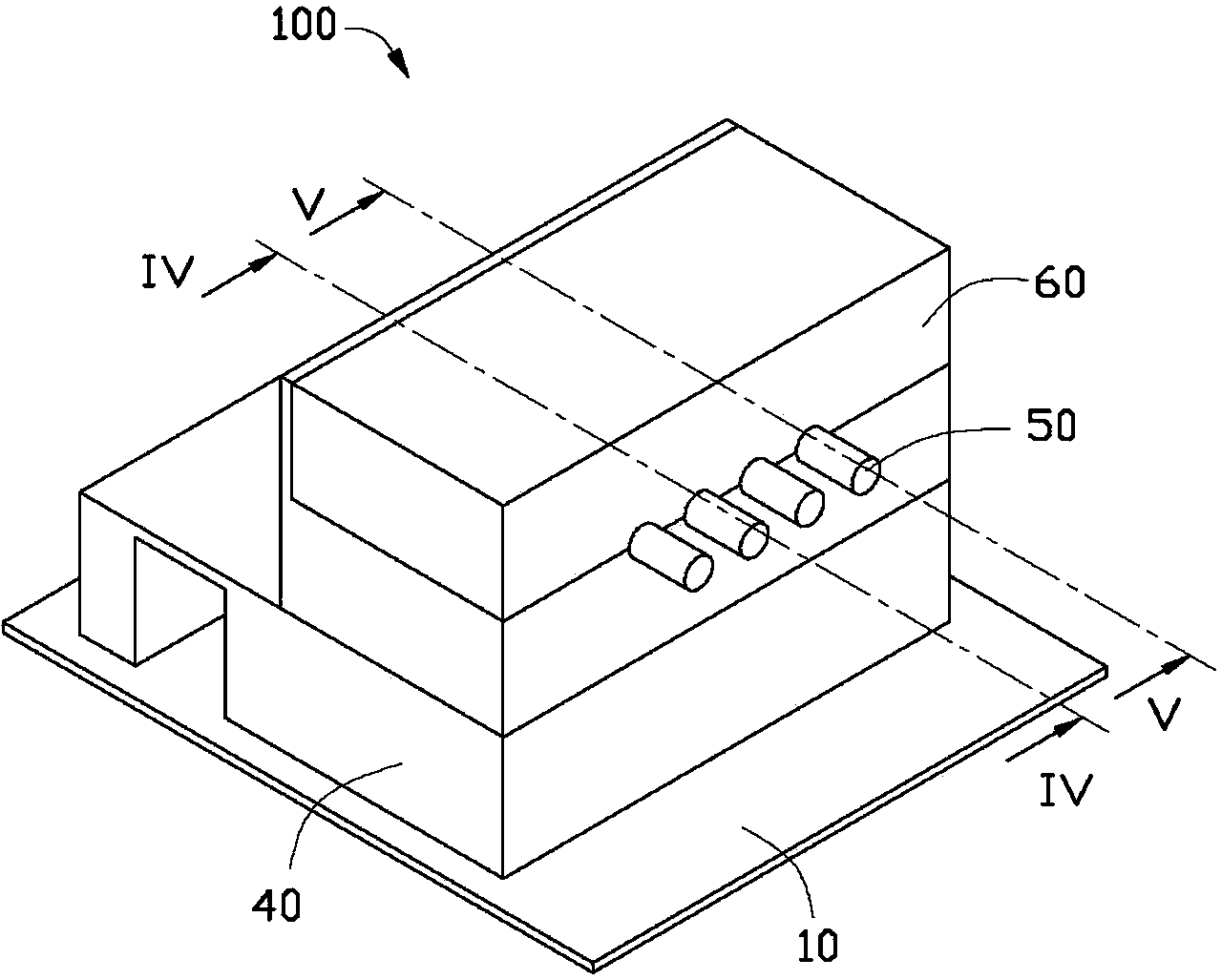

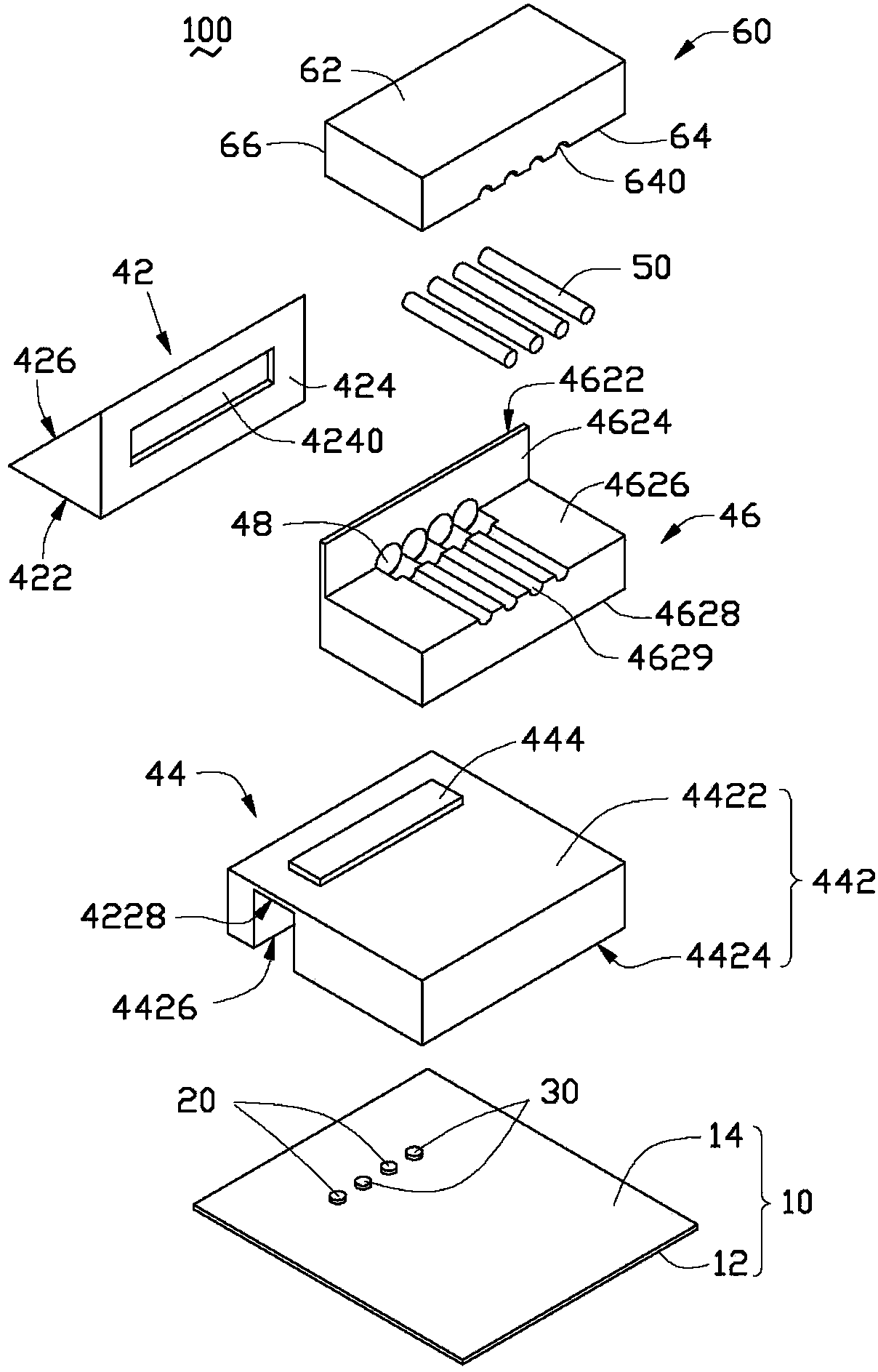

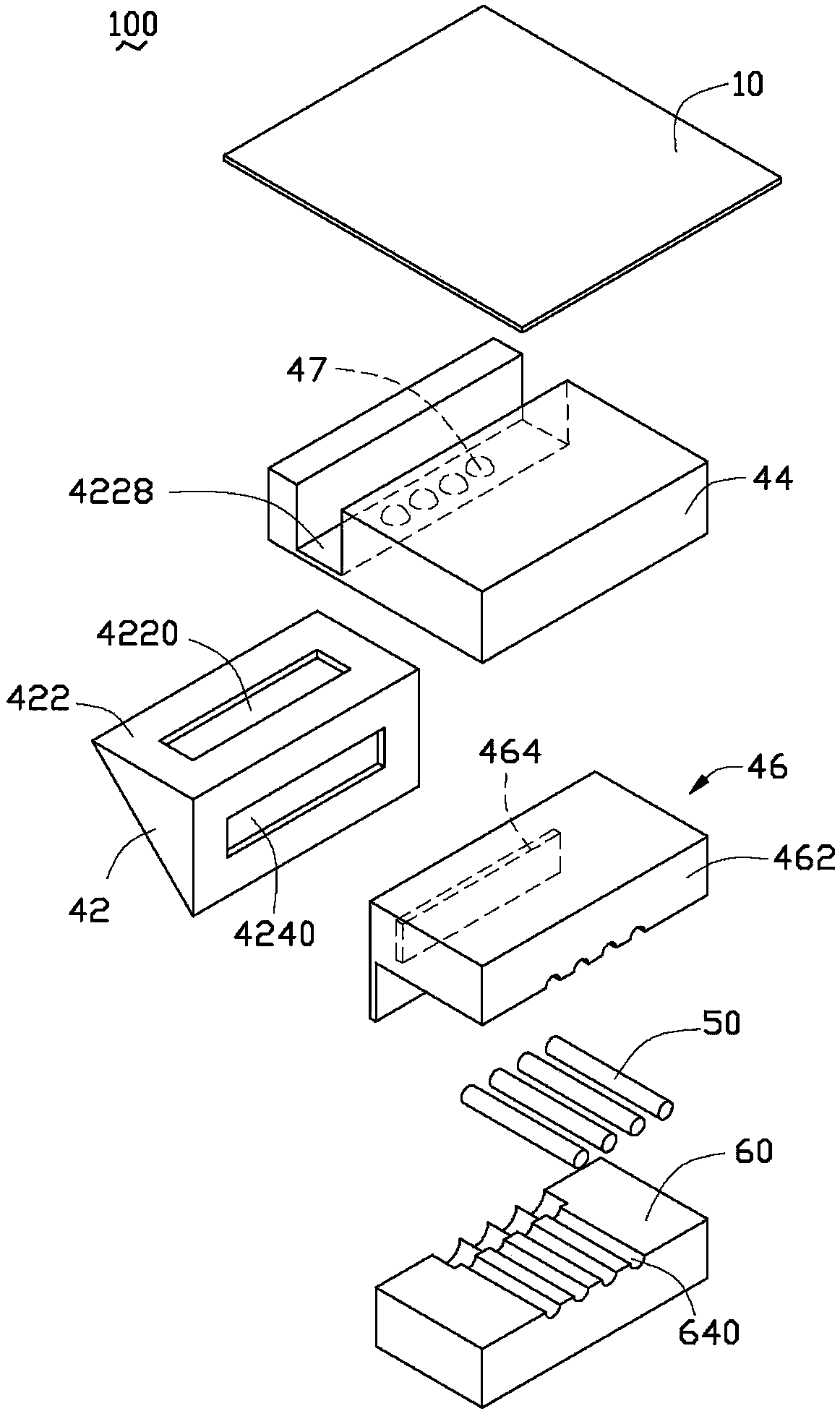

[0017] Please also refer to figure 1 and figure 2 , is the optical fiber coupling connector 100 provided by the embodiment of the present invention. The fiber coupling connector 100 includes a circuit board 10 , two light emitting modules 20 , two light receiving modules 30 , an optical coupling lens 40 , four optical fibers 50 and a cover 60 .

[0018] Please also refer to figure 2 and image 3 , the circuit board 10 includes a bottom surface 12 and a top surface 14 . The bottom surface 12 and the top surface 14 are located on opposite sides of the circuit board 10 , and the bottom surface 12 is parallel to the top surface 14 .

[0019] The two light-emitting modules 20 and the two light-receiving modules 30 are fixed on the top surface 14 and are electrically connected to the circuit board 10 . Specifically, the two light emitting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap