Magnetic field controlled silicon-based non-volatile resistance variable device and preparation method thereof

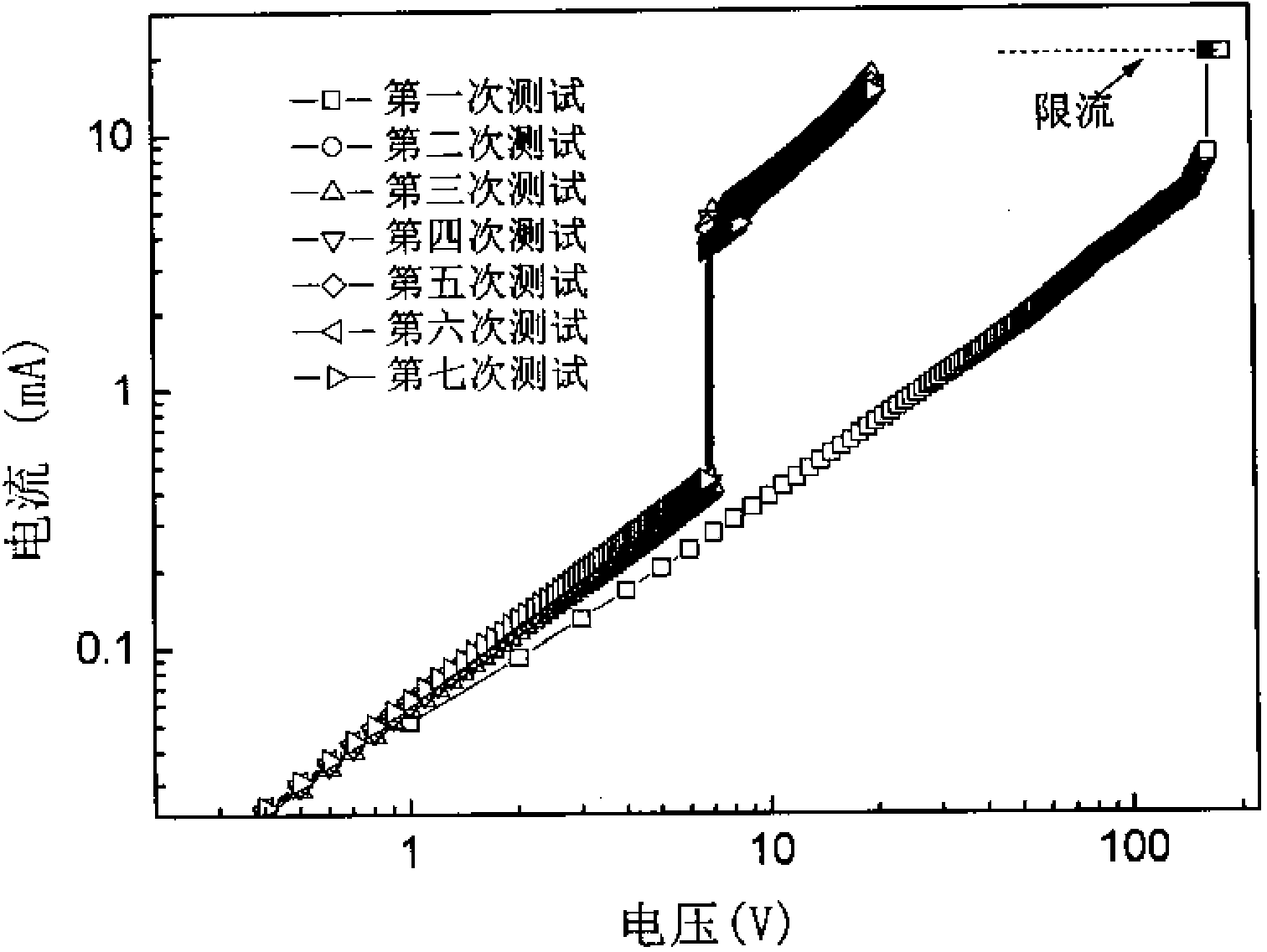

A non-volatile, resistive device technology, applied in electrical components and other directions, can solve the problems of no magnetoresistance effect and inability to magnetic sensing, and achieve the effect of significant magnetoresistance effect, simple preparation process and moderate price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

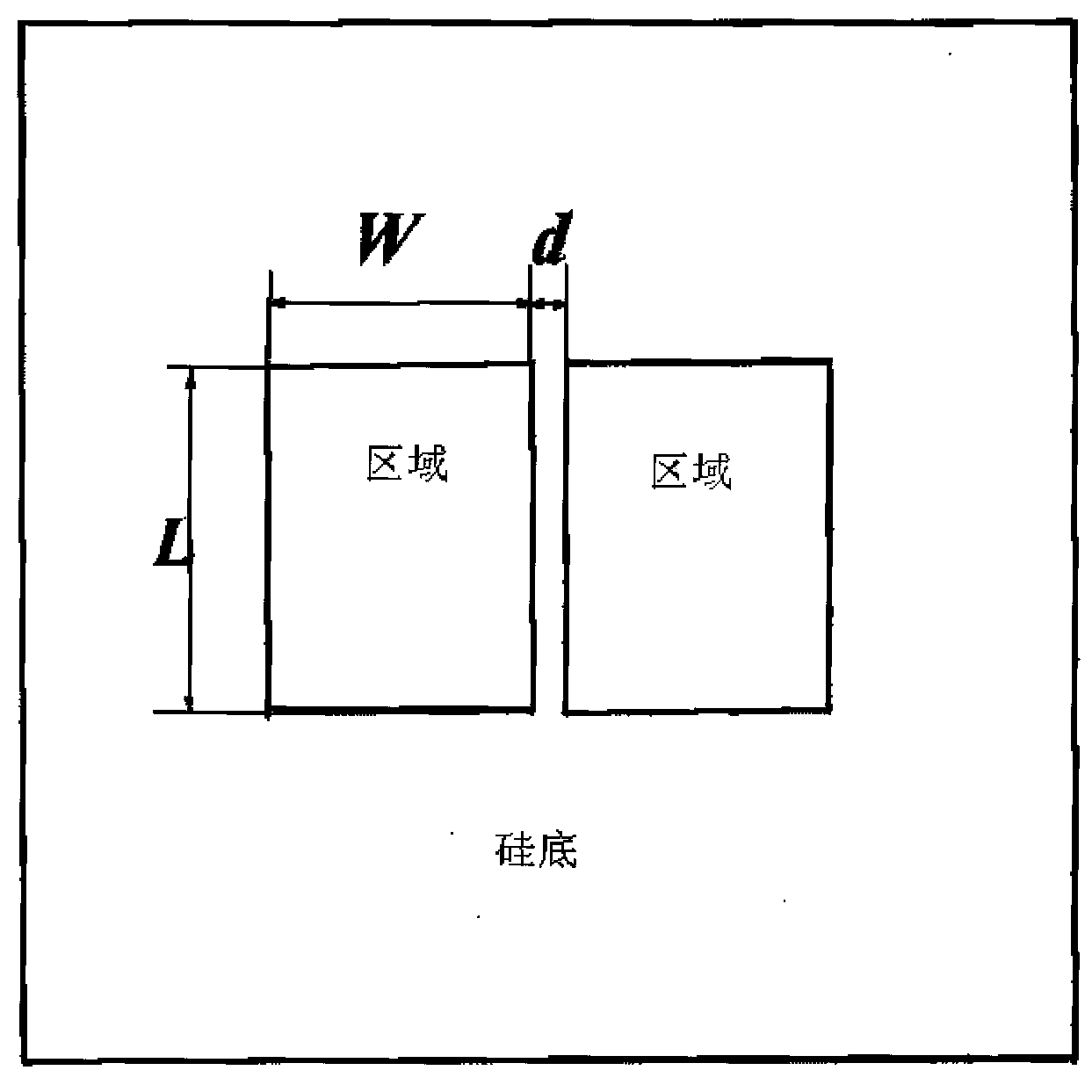

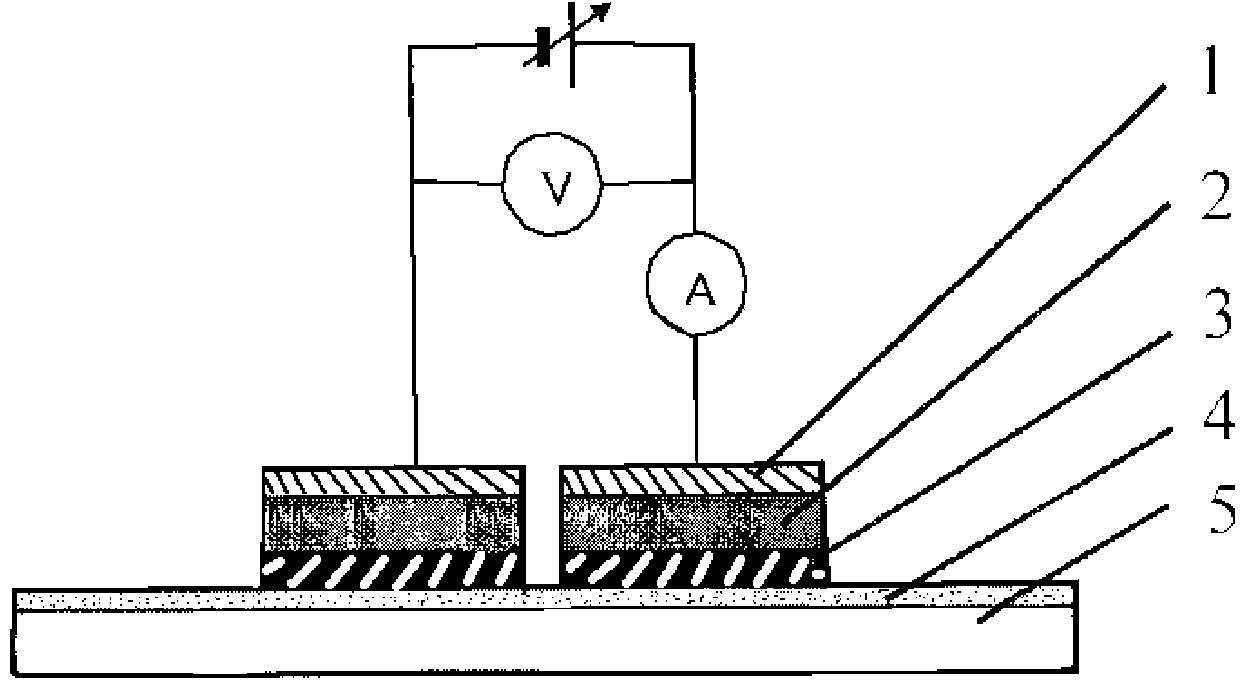

[0035] Rinse the n-type silicon (111) and the substrate with a resistivity of 3200Ω·cm with alcohol or acetone, and cut it into a length of 11.0×12.0mm 2 rectangle. At room temperature (300K) and cavity pressure of 1.8×10 by using a mask and laser pulse deposition method -4 Deposit 20nm thick high-purity MgO (purity>99.995%), 60nm thick high-purity Mg (purity>99.99%) and 20nm thick high-purity Ag (purity>99.99%) in the center of the rectangular silicon substrate in sequence under Pa. The dimensions of the two regions are the same, L=2mm in the length direction, W=1.5mm in the width direction, and d=0.1mm apart in the width direction. So far, a silicon-based nonvolatile resistive switching device with controllable magnetic field has been prepared.

Embodiment 2

[0037] Rinse the n-type silicon (100) substrate with a resistivity of 4000Ω·cm with alcohol or acetone, and cut it into a length of 11.0×12.0mm 2 rectangle. At room temperature (300K) and cavity pressure of 1.8×10 by using a mask and laser pulse deposition method -4 Deposit 40nm thick high-purity MgO (purity>99.995%), 80nm thick high-purity Mg (purity>99.99%) and 40nm thick high-purity Ag (purity>99.99%) in the center of the rectangular silicon substrate in sequence under Pa. The dimensions of the two regions are the same, L=1.8mm in the length direction, W=1.2mm in the width direction, and d=0.5mm apart in the width direction. So far, a silicon-based non-volatile resistive device with controllable magnetic field has been prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com