Tube head equipped with a lid, associated with an improved perforating cap which ensures protection of the lid prior to first use thereof

A tube head and punch technology, applied in the field of flexible tubes, can solve problems such as infeasible solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

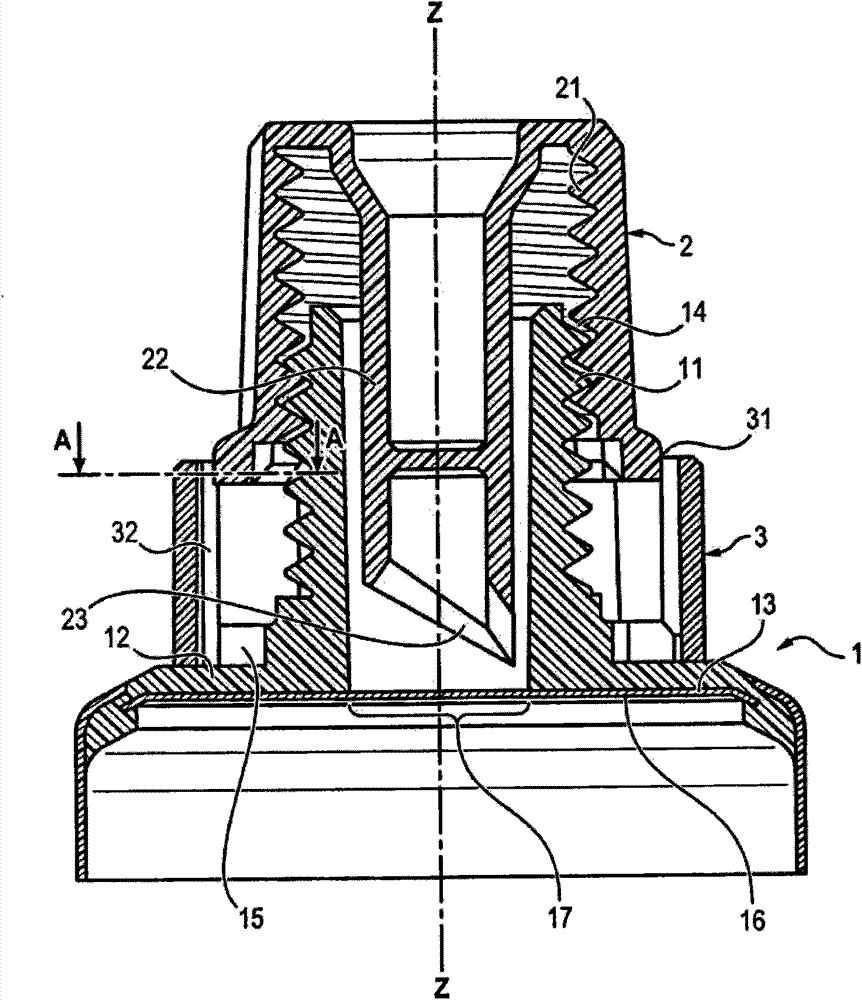

[0028] figure 1 An embodiment of an assembly according to an aspect of the invention is shown, comprising

[0029] - pipe head 1,

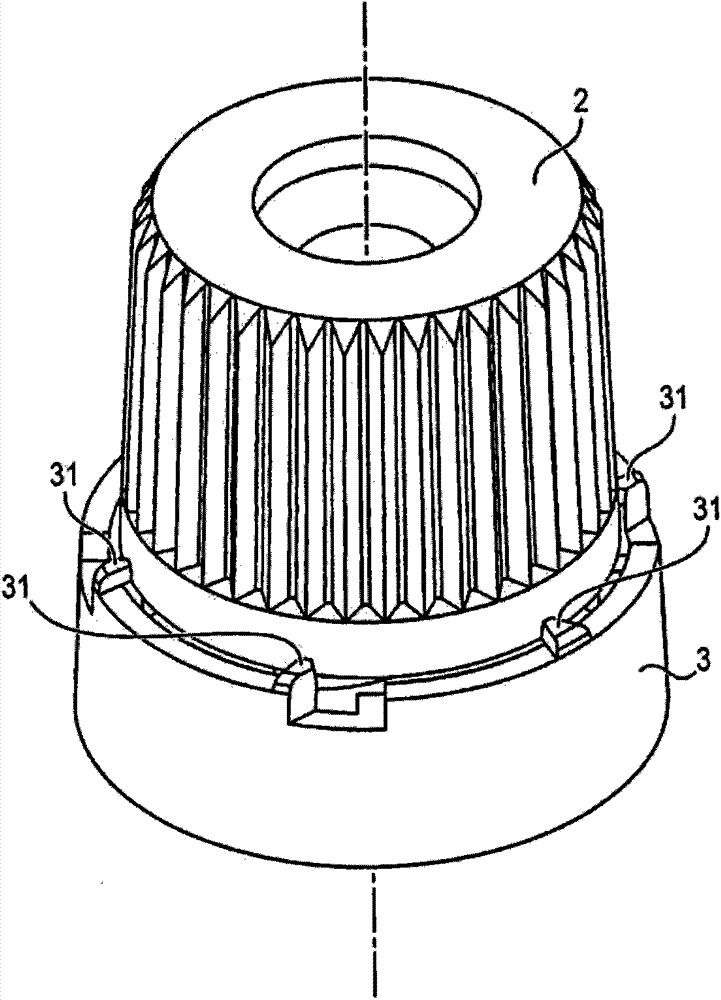

[0030] - Cap 2, and

[0031] - Removable spacer ring 3.

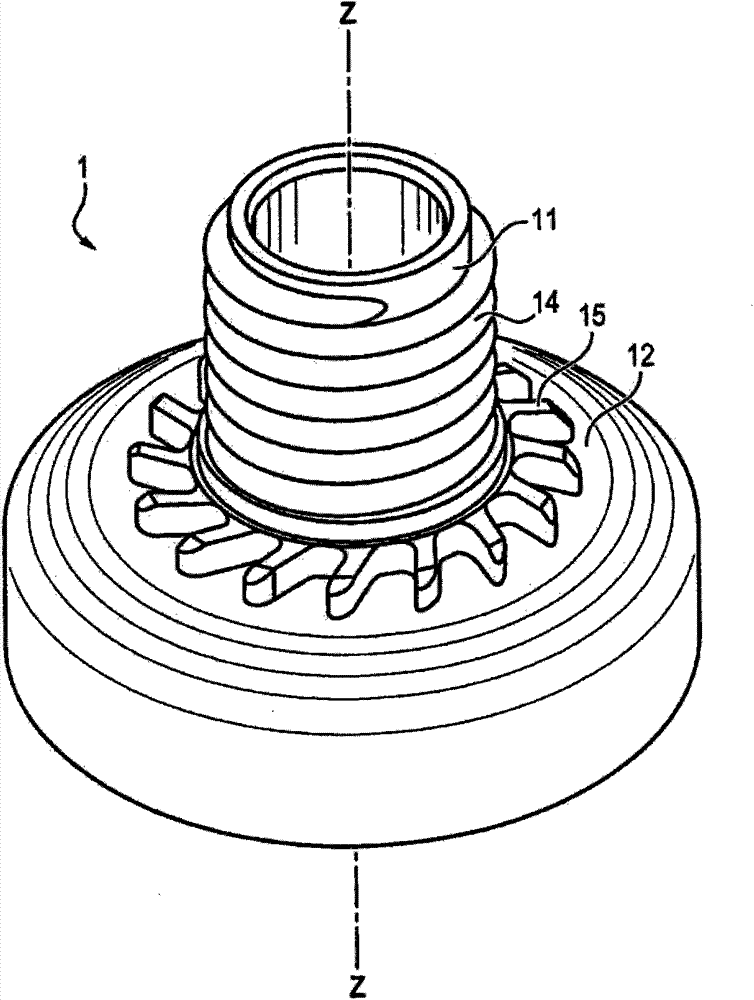

[0032] Tube head 1 comprises a neck 11 defining a longitudinal axis Z-Z, a shoulder 12 and a solid insert 13 formed as a cap closing said neck 11 .

[0033] More precisely, insert 13 comprises a peripheral portion 16 , typically frusto-conical or disc-shaped, and a central portion 17 , the diameter of which typically corresponds to the internal diameter of neck 11 , forming said cap.

[0034] The neck 11 comprises on its outer circumference a thread 14 adapted to enable the cap 2 to be screwed onto the neck 11 .

[0035] The cap 2 comprises an internally tapped thread 21 adapted to cooperate with the thread 14 of the neck 11 , and a punch 22 configured to be inserted into the neck 11 of the tube head 1 when the cap 2 is screwed onto said neck 11 . The longitudinal direction of the cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com