Pump assembly

A technology for pump devices and pump housings, applied to pumps, parts of pumping devices for elastic fluids, piston pumps, etc., can solve problems such as cost improvement, improve life, reduce installation errors, and ensure relative positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

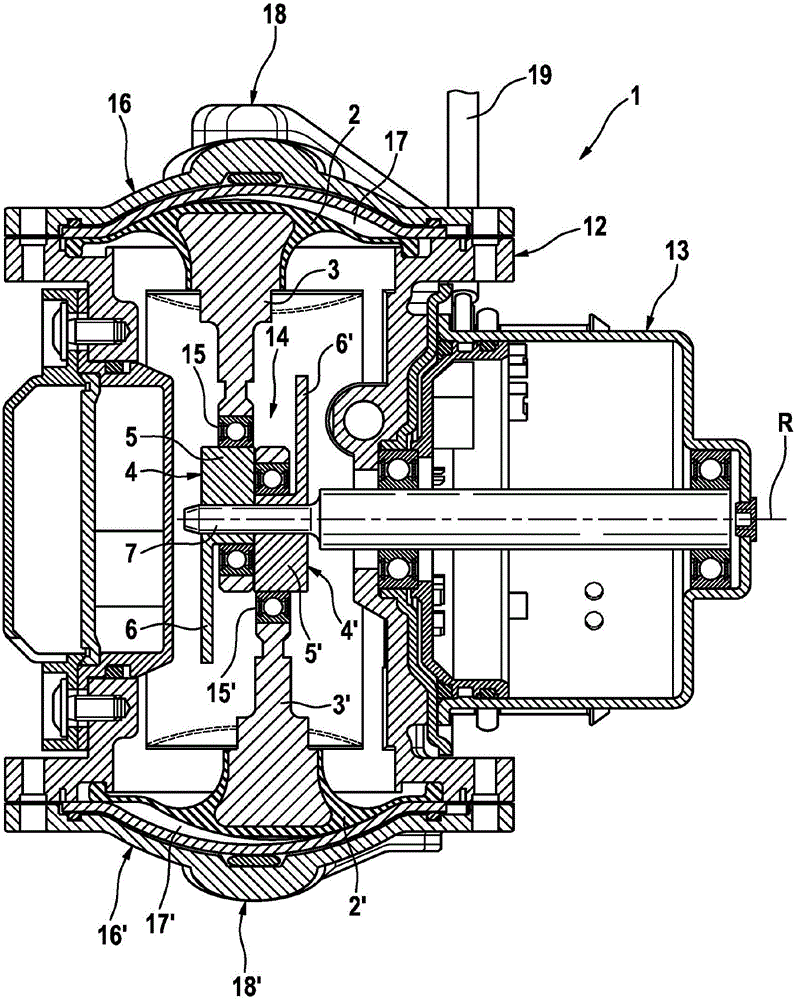

[0026] figure 1

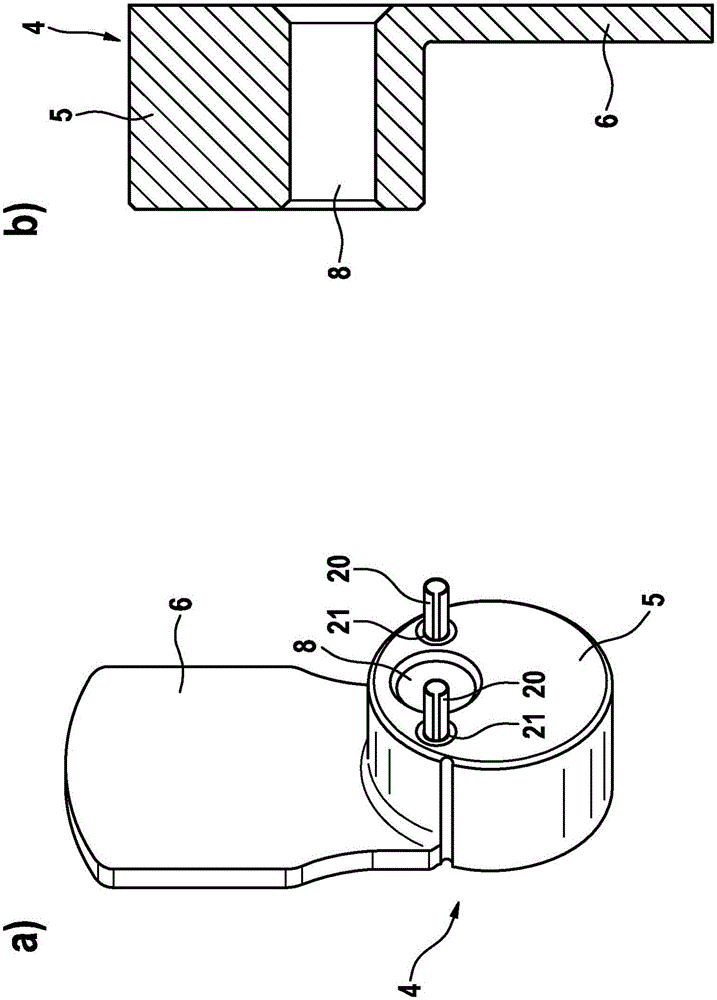

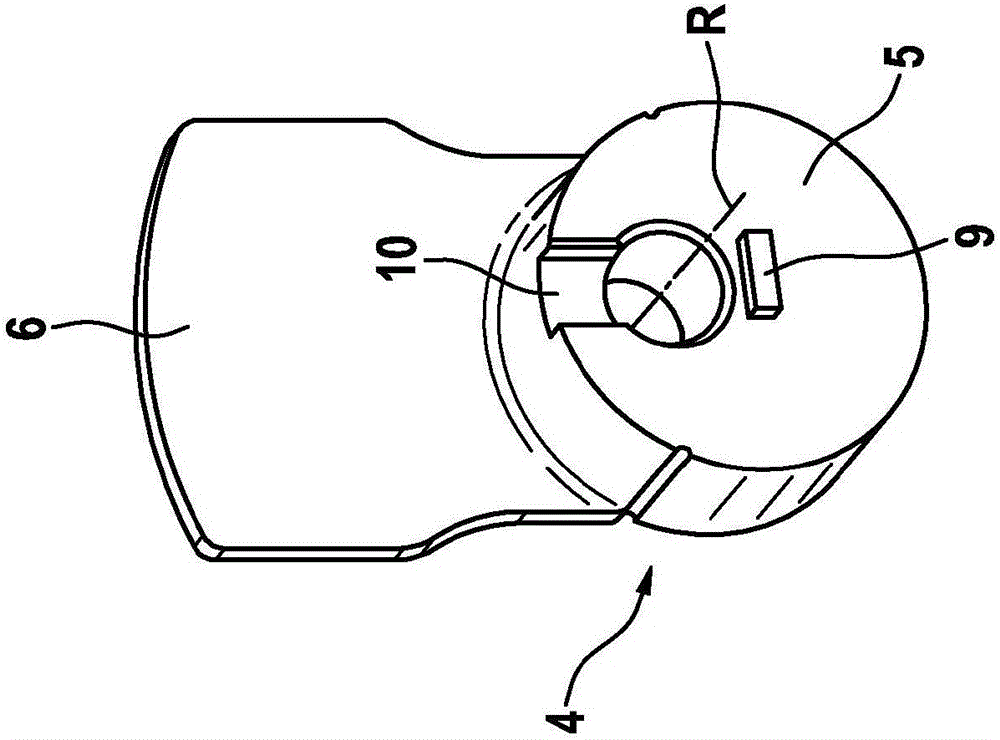

[0027] The known pump device 1 has a pump housing 12 and an electric drive 13 which moves a crankshaft linkage 14 via a drive shaft 7 . The two eccentric elements 4 , 4 ′ are arranged adjacent to one another on the drive shaft 7 and essentially each have an approximately cylindrical bearing element 4 and a counterbalance connected to the bearing element 4 or 4 ′ on one side. Element 5 or 5'. The center points of the two support elements 4, 4' are arranged offset relative to each other at a rotation angle of 180° around the axis of rotation R. In order to keep these prescribed rotational angular positions of the two eccentric elements constant relative to each other, the eccentric elements have as in figure 2 The anti-torsion structure described in. The crankshaft linkage 14 has two connecting rods 3, 3', which are rotatably fixed on bearing elements 5, 5' via ball bearings 15, 15', respectively. The connecting rods 3, 3' end in elastic pressing elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com