A device for measuring the tiny thrust of an engine with an adjustable range

A technology for engine and type adjustment, applied in the field of force measurement, can solve the problems of the influence of the measurement system, inconvenient use, excessive changes in the zero point of the equipment, etc., and achieve the effect of avoiding random changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

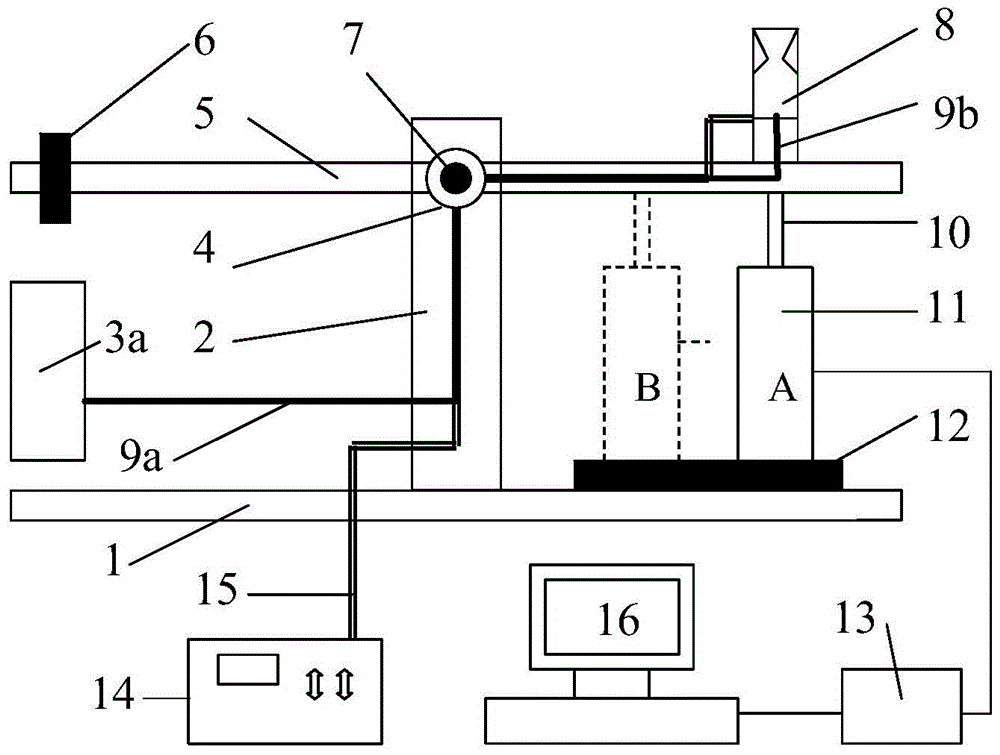

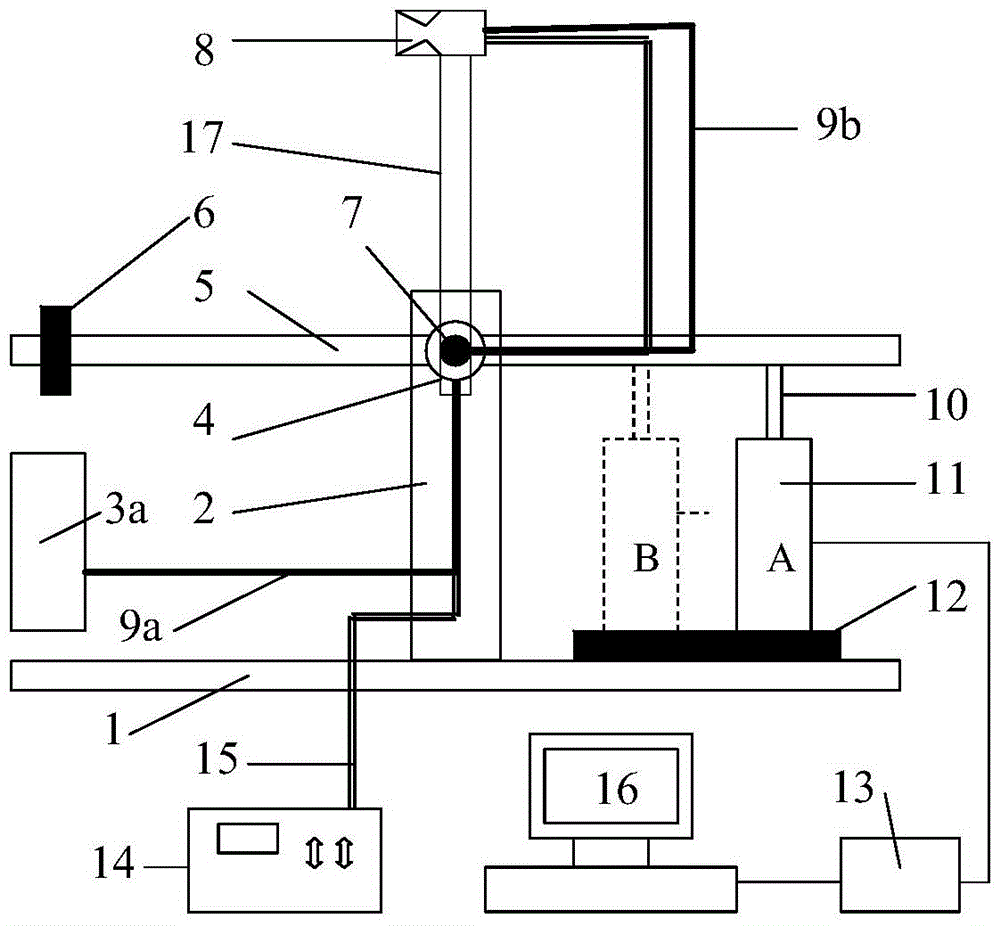

[0017] Below in conjunction with the accompanying drawings, the specific structure, working principle and working process of the present invention will be further described.

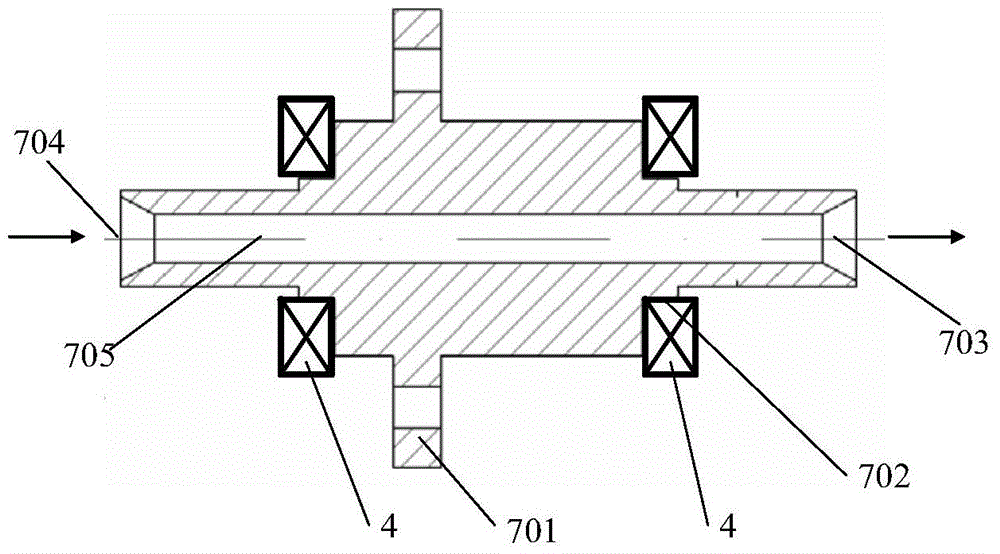

[0018] figure 1 It is a schematic structural diagram of an embodiment of the first technical solution provided by the present invention. The device includes a base 1, a propellant storage tank 3a, a beam 5, a counterweight 6, an engine 8, a propellant pipeline, and an electric control box 14 , force sensor 11, signal processing unit 13 and computer 16, ladder support shaft 7, vertical beam 2, two bearings 4 and force sensor fixed support 12; Vertical beam 2 is installed on the base 1, and the outer ring of each bearing is installed with The bearing seat on the vertical beam is fixedly connected, and the inner rings of the two bearings are respectively in interference fit with the two bearing step mating surfaces 702 of the stepped support shaft 7; The inlet of the flow channel is connected with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com