Sheet metal stamping device

A technology of stamping device and sheet metal parts, applied in the field of sheet metal parts stamping device, can solve the problems such as the inability of the buffer structure to achieve the buffer effect, increase the consumption of raw materials of the sheet metal material plate, and the stamping process cannot be carried out normally, so as to shorten the abnormal processing. The effect of reducing time, reducing losses and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

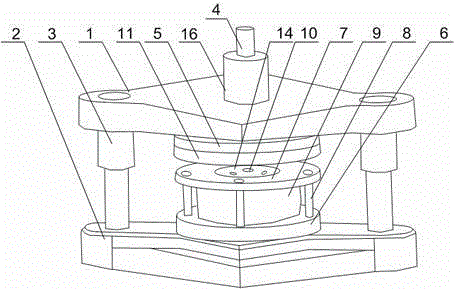

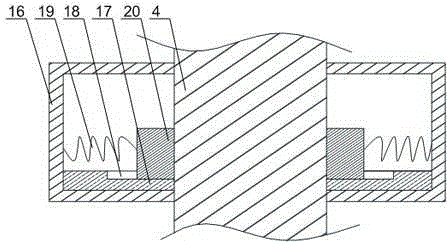

[0022] like Figure 1 to Figure 3As shown, the stamping device for sheet metal parts of the present invention includes an upper mold base 1 and a lower mold base 2, the upper mold base 1 and the lower mold base 2 are connected by a support rod 3, and the lower mold base 2 is installed on the working platform of the stamping machine. Punch head 4 is installed in described upper mold base 1, upper mold fixed plate 5 is installed on described upper mold base 1, lower mold fixed plate 6 is installed on described lower mold base 2, upper mold fixed plate 5 There is a through hole on the top, and an annular plate 7 is arranged on the lower mold fixing plate 6, and the annular plate 7 is connected with the lower mold fixing plate 6 through a plurality of screw rods 8; it also includes a rubber block 9, and the rubber block 9 It is arranged between the annular plate 7 and the lower mold fixing plate 6, and is located inside the annular ring formed by a plurality of screw rods 8. The r...

Embodiment 2

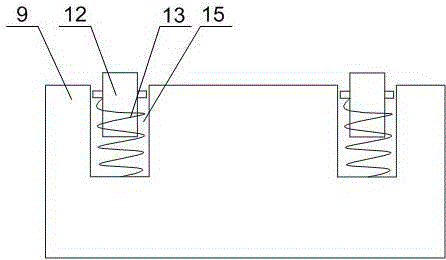

[0024] Such as figure 2 As shown, in this embodiment, on the basis of Embodiment 1, an ejector mechanism is also installed on the rubber block 9, and the ejector mechanism includes a push rod 12, a blind hole is provided on the rubber block 9, and the push rod 12 is connected to the bottom of the blind hole by a spring 13, and the diameter of the push rod 12 decreases gradually along the direction of the lower mold base 2. After the stamping head 4 punches, the rubber block 9 is compressed and deformed, the ejector rod 12 moves down, and the spring 13 is also compressed at the same time. Under the action, the formed sheet metal parts located in the middle gap of the annular plate 7 are ejected, so as to facilitate the next blanking quickly.

Embodiment 3

[0026] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a leveling plate 11 , the leveling plate 11 is slidably arranged on the outer wall of the stamping head 4 , and the leveling plate 11 is an annular member. When the sheet metal material plate is punched by the stamping head 4, curling or protrusions will appear on the edge of the remaining part of the material plate, and the flattening plate 11 will move downward together with the stamping head 4. When shifting, the remaining part of the material plate will not produce any curling or protrusion under the clamping action of the flat plate 11 and the annular plate 7. After the first punching is completed, adjust the material plate to continue the second punching. Cutting, thereby reducing the loss of material plates to the greatest extent, and reducing the production cost of sheet metal parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com