A desktop screw tightening machine

A technology for tightening machines and screws, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve problems that affect assembly quality, limit blowing technology, and affect service life, and achieve the effect of convenient picking up screws and fast and efficient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

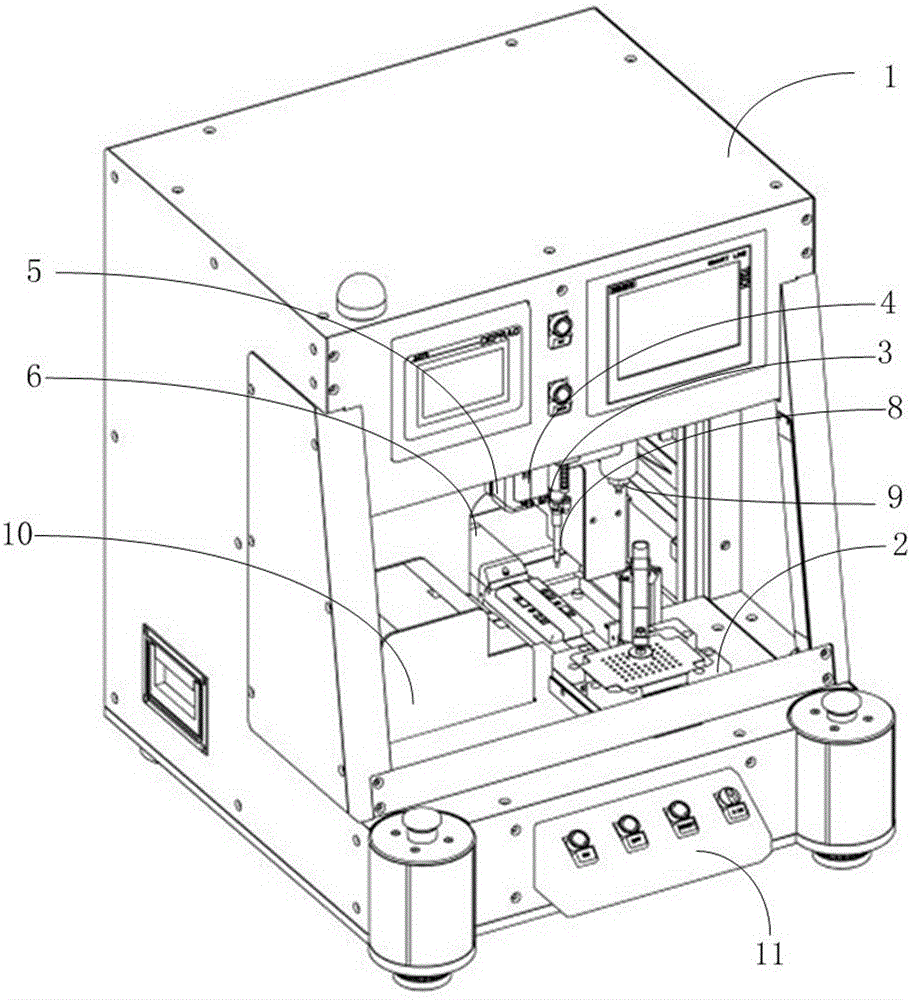

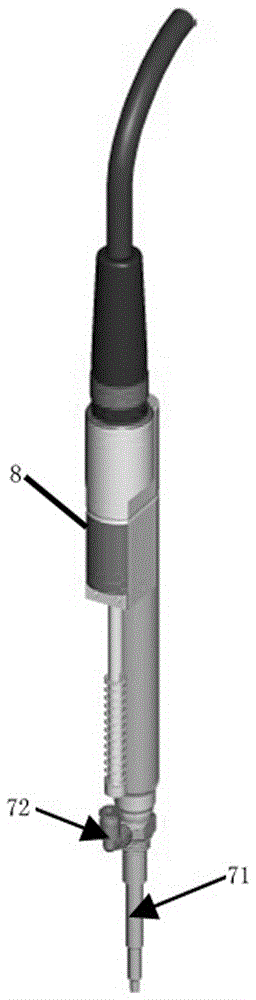

[0019] Such as figure 1 and figure 2 As shown, a desktop screw tightening machine includes a case shell 1, a workpiece loading platform 2, a tightening unit 3, a bracket 4, a positioning unit 5 and a screw storage unit 6, and the workpiece loading platform 2 and the screw storage unit 6 are arranged on the box casing 1 At the inner bottom, the tightening unit 3 is installed on the support 4, and the support 4 is movably connected to the inner top of the box shell 1 and driven by the positioning unit 5. The tightening unit 3 travels back and forth to the workpiece loading platform 2 under the condition that the positioning unit 5 drives the support 4 And storage screw unit 6, particularly, tighten...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap