A book block centering device for a book case loading machine

A technology of book block and case machine, which is applied in the direction of book cover, book binding, printing, etc., which can solve the problems of affecting the glue effect and low efficiency, and achieve the effects of simple structure, reduced working pressure and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

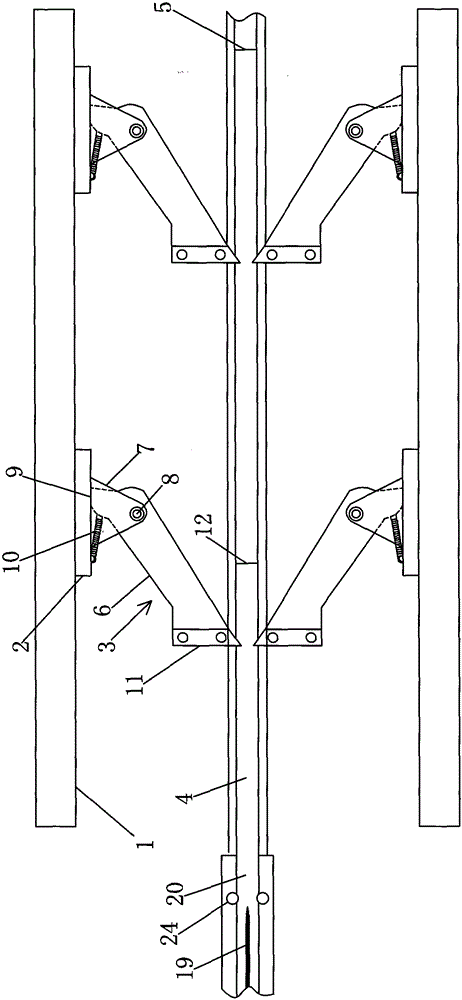

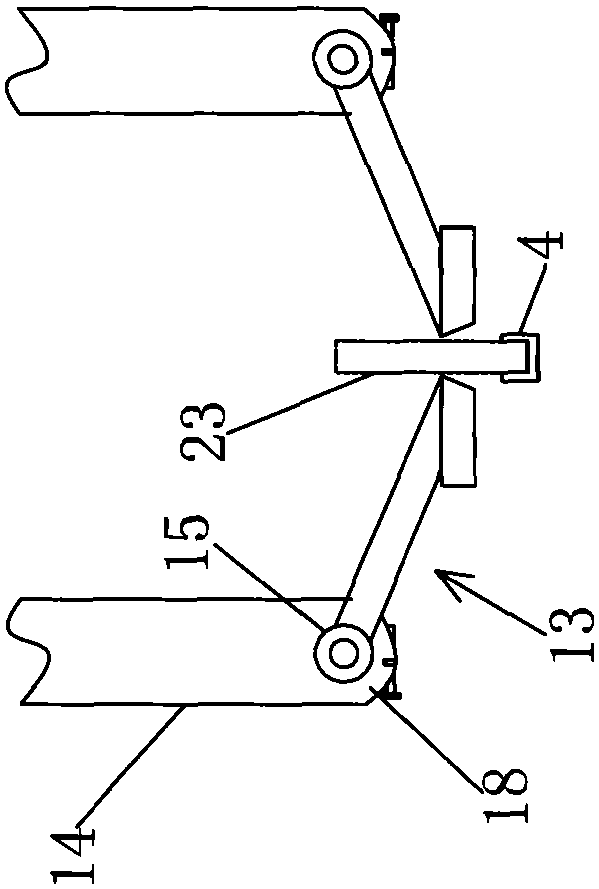

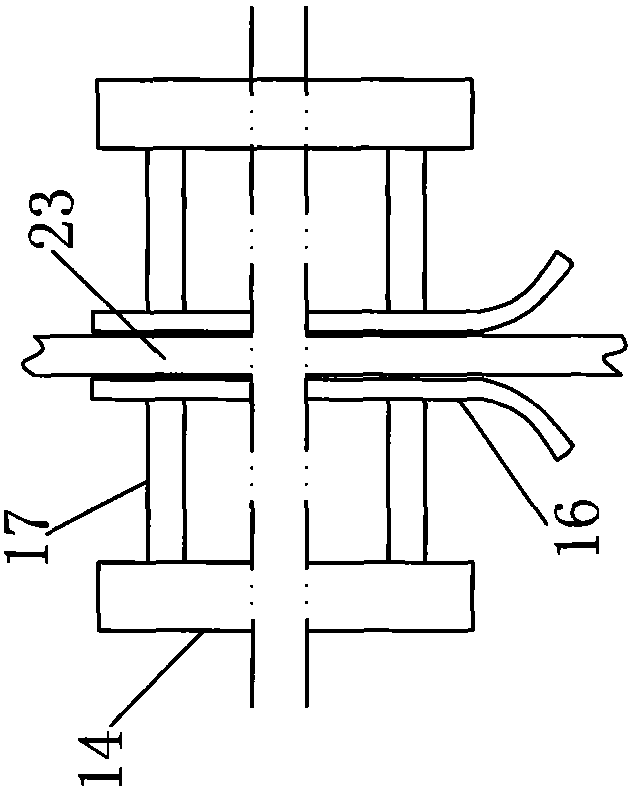

[0033] Embodiment: a kind of book block centering device for the book case machine, such as Figure 1-6 As shown, it includes a pair of slide rails 1, a pair of slide plates 2, and at least a pair of push gauges 3 for pushing the book block forward. The push gauge 3 is symmetrically installed on the slide plate 2, and the slide plate 2 Moving back and forth along the slide rails 1, a slideway 4 for transferring book blocks is provided between a pair of slide rails 1, and a start step 5 is provided at the beginning of the slideway 4.

[0034] Such as figure 1 , 4, 5, the push gauge 3 includes a push arm 6, the tail of the push arm 6 is hinged with the support plate 7, and the tail end of the push arm 6 is against the slide plate 2 and the rotation is limited and can only rotate in a small range, specifically In other words, the vertical distance from the hinge point 8 of the push arm 6 to the slide plate 2 is smaller than the distance from the hinge point 8 of the push arm to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com