All-in-one machine for testing soil engineering tension-compression strength

A technology of strength test and integrated machine, which is applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, and measuring devices, which can solve the problems of low test repetition rate, no standard mold, and inability to measure the tensile strength of soil Influence and other issues to achieve the effect of improving accuracy and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

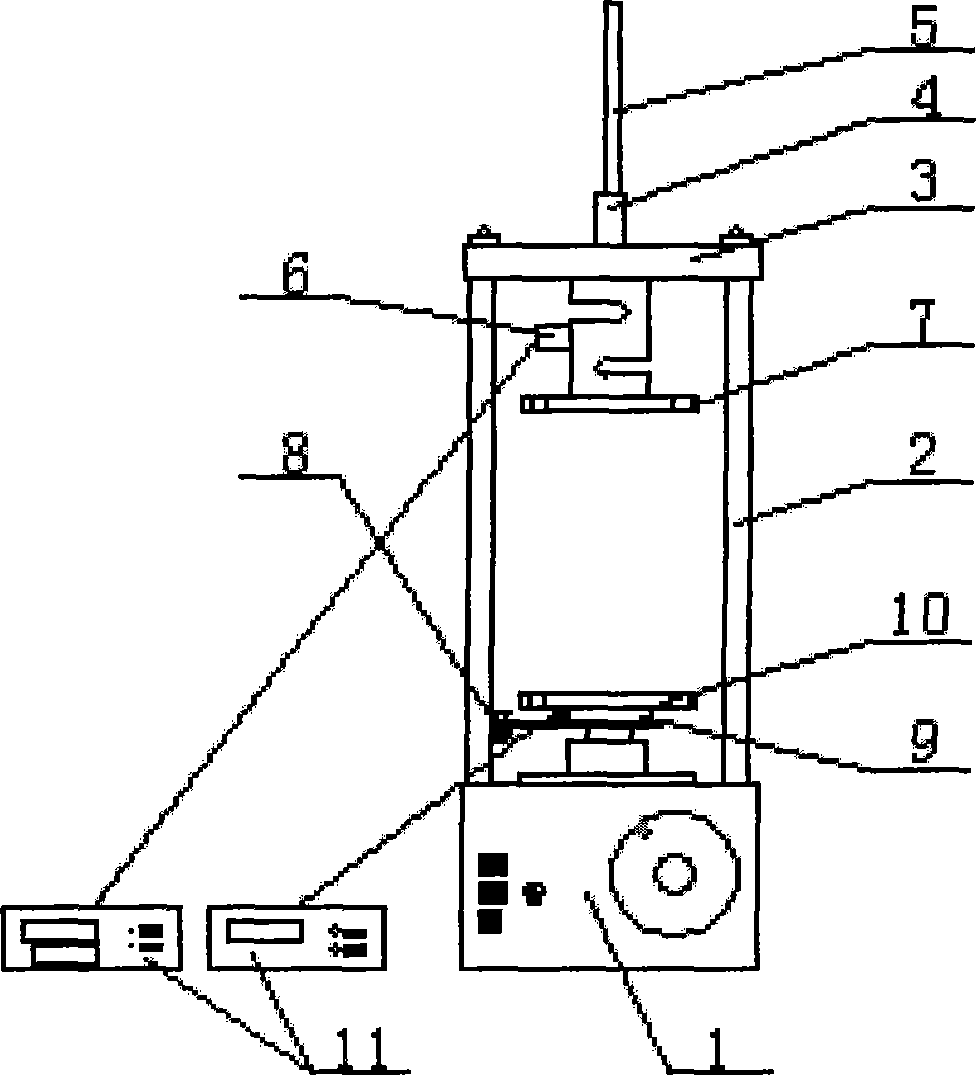

[0043] see figure 1 , the specific embodiment is realized by adopting the following technical scheme, which includes a console 1, one side of the console 1 is provided with corresponding driving wheels and control devices, and fixed Rod 2, a positioning rod 3 is arranged between the upper ends of the fixed rods 2, and the positioning rod 3 and the fixed rod 2 are screwed and fixed by bolts, and the middle part of the positioning rod 3 is provided with a locking nut 4. The threaded hole of the locking nut 4 is provided with a threaded screw 5 that is screwed together, and the lower end of the screw 5 passes through the positioning rod 3 and is connected with the S-type tension and compression stress sensor 6, and the S-type tension and compression stress sensor 6 is The bottom of the upper universal top seat 7 is installed, the upper end surface of the console 1 is provided with a displacement measuring platform 8, the upper end surface of the displacement measuring platform 8 ...

Embodiment 2

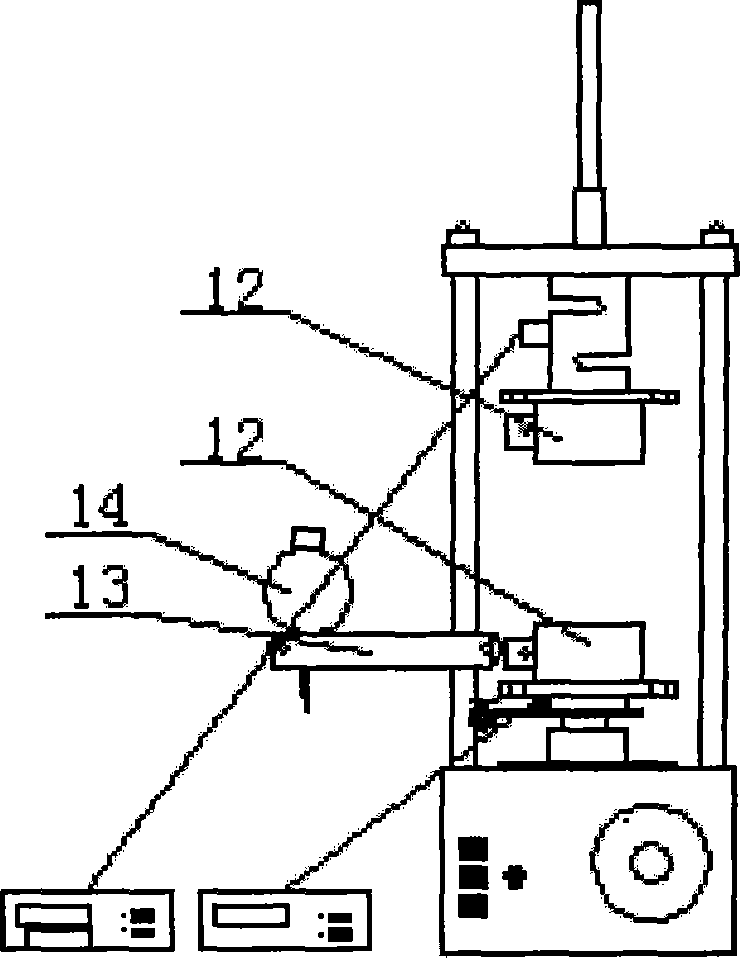

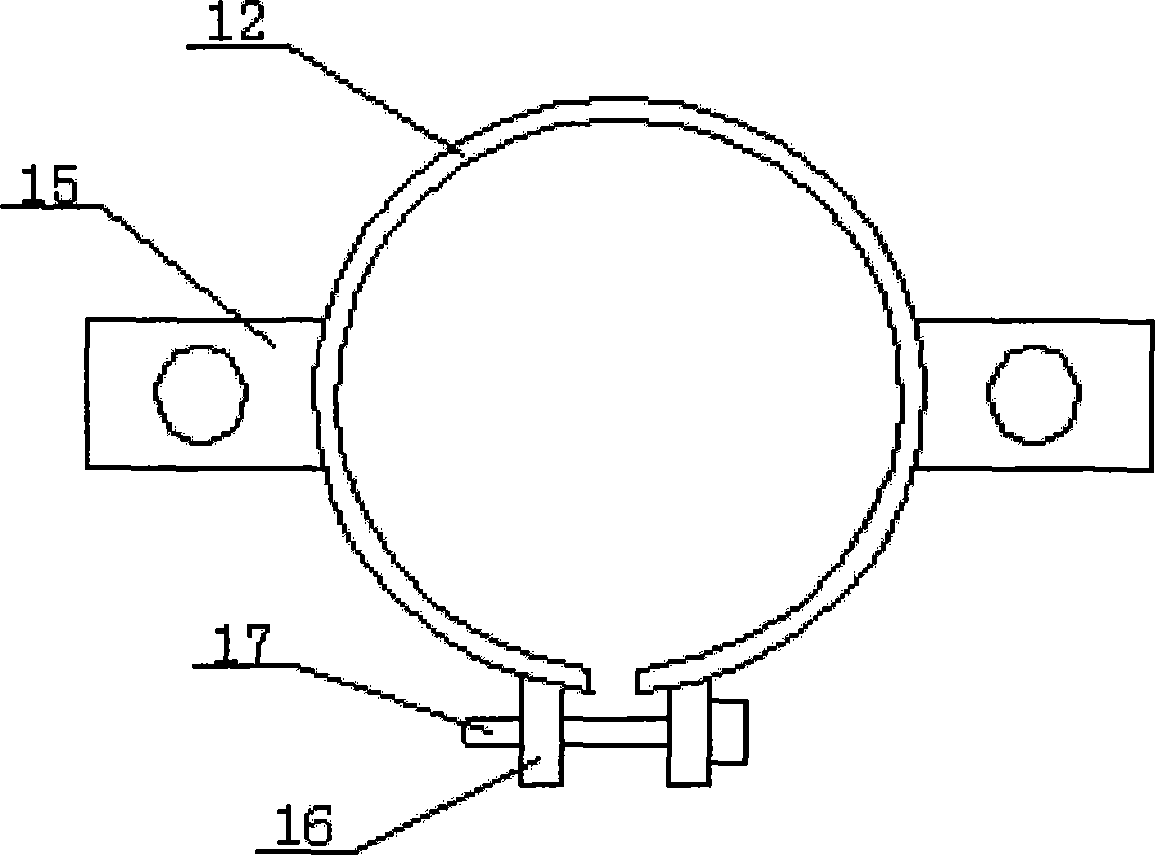

[0045] When performing tensile tests, see Figure 2-3 , the upper universal top seat 7 and the lower universal base 10 in embodiment 1 are mirrored with a clamp 12, and the fixed rod 2 on one side of the console 1 is clamped with a clamping frame 13, and the other end of the clamping frame 13 is A dial indicator 14 is fixed, and the clamp 12 is a hollow tubular structure as a whole, and an anti-slip thread is rolled on its inner wall. The bottom of the clamp 12 is mirror-welded with a mounting base 15, and one side of the clamp 12 is An opening is provided, and fixing nuts 16 are respectively welded on both sides of the opening, and the two fixing nuts 16 are screwed and connected by bolts 17 .

[0046] (1), sample preparation.

[0047] The soil sample is made into a cylinder with a diameter of 61.8mm and a height of 125mm;

[0048] (2) Soil sample installation.

[0049] a), adjust the screw rod 5 through the lock nut 4, so that the vertical distance between the upper unive...

Embodiment 3

[0055] When conducting radial fracturing tests, see Figure 4-5 , the upper universal top seat 7 and the lower universal base 10 are equipped with a fracturing mold 18 as a mirror image, and the described fracturing mold 18 has a disc-shaped structure as a whole, and grooves are opened radially on the side in contact with the test piece 19. A radial fracturing test splitting bar 23 is placed in the groove 19, and the outer surface of the radial fracturing test cleaving bar 23 extends out of the end surface of the mold 18.

[0056] (1), sample preparation.

[0057] The soil sample is made into a cylinder with a diameter of 61.8mm and a height of 125mm or a diameter of 39.1mm and a height of 80mm. The soil sample can also be made into a cube according to the test requirements;

[0058] (2) Soil sample installation.

[0059] a), adjust the stroke track through the lock nut 4, so that the vertical distance between the upper universal top seat 7 and the lower universal base 10 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com