Optical Plate With Microstructures

一种微结构、光学板的技术,应用在光学板领域,达到降低热点问题、提升混光程度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

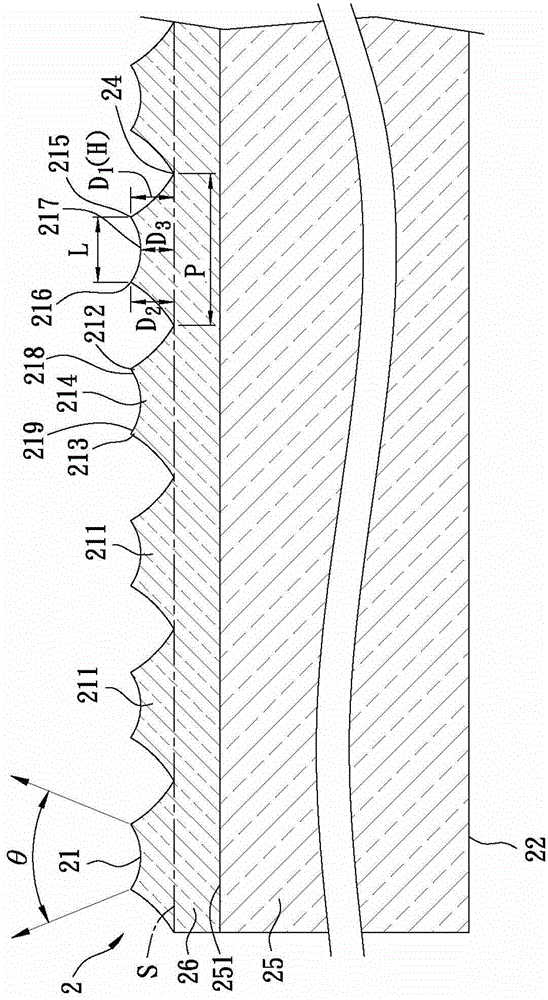

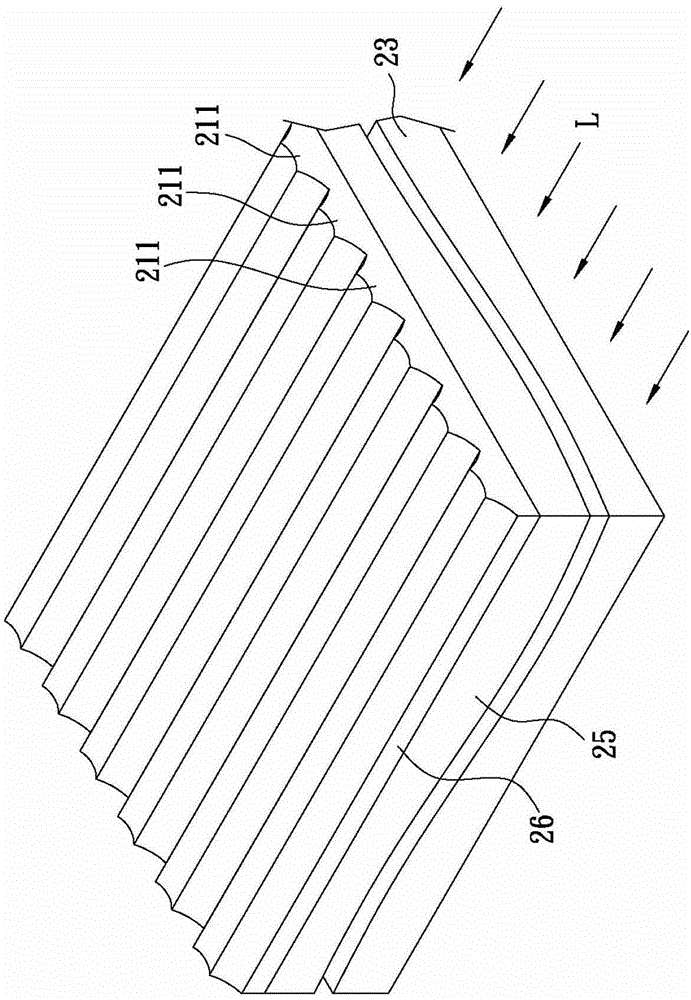

[0029] refer to figure 2 , image 3 , the first preferred embodiment of the optical plate with microstructures of the present invention comprises a substrate 2 .

[0030] The substrate 2 includes a light-emitting surface 21, a back surface 22 opposite to the light-emitting surface 21, and a side surface 23 connecting the light-emitting surface 21 and one side of the back surface 22. The light-emitting surface 21 is formed with a plurality of parallel microstructures 211, And the microstructures 211 extend in the same direction.

[0031] Wherein, the vertical section of each microstructure 211 extending in parallel has a first convex portion 212 and a second convex portion 213 spaced apart from each other, and a concave portion 214 connecting the first convex portion 212 and the second convex portion 213, wherein, The vertical section of each microstructure 211 refers to the direction perpendicular to the extending direction of the microstructure.

[0032] The microstructur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com