Method for determining weak rods in truss structures of hoisting and conveying machinery

A technology for lifting and transporting machinery and truss structures, which is applied in special data processing applications, instruments, electrical digital data processing, etc. The effect of increasing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

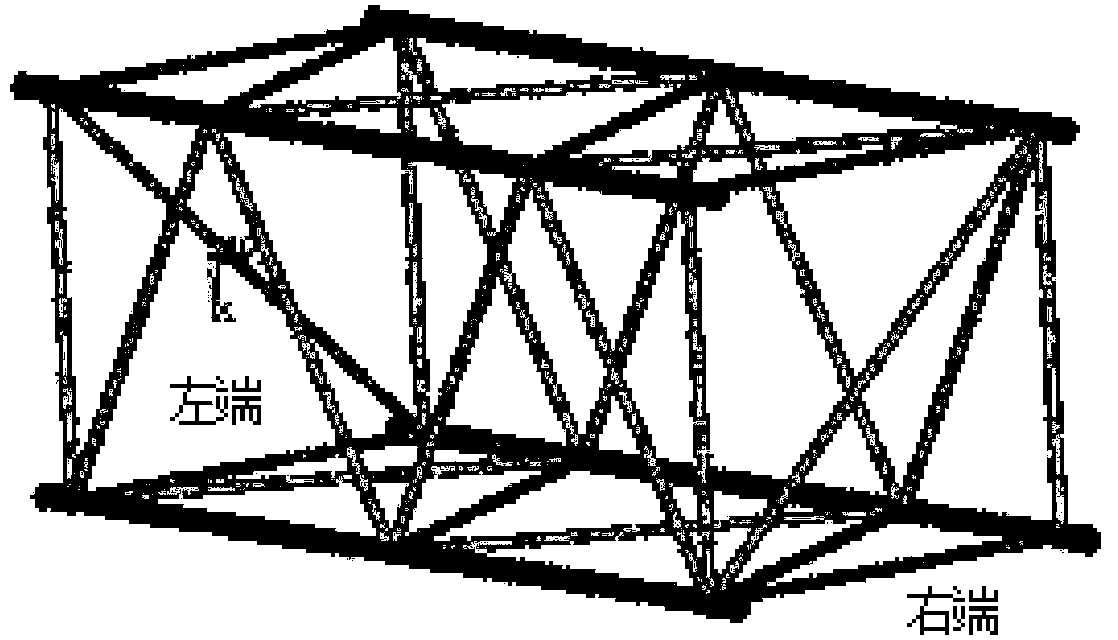

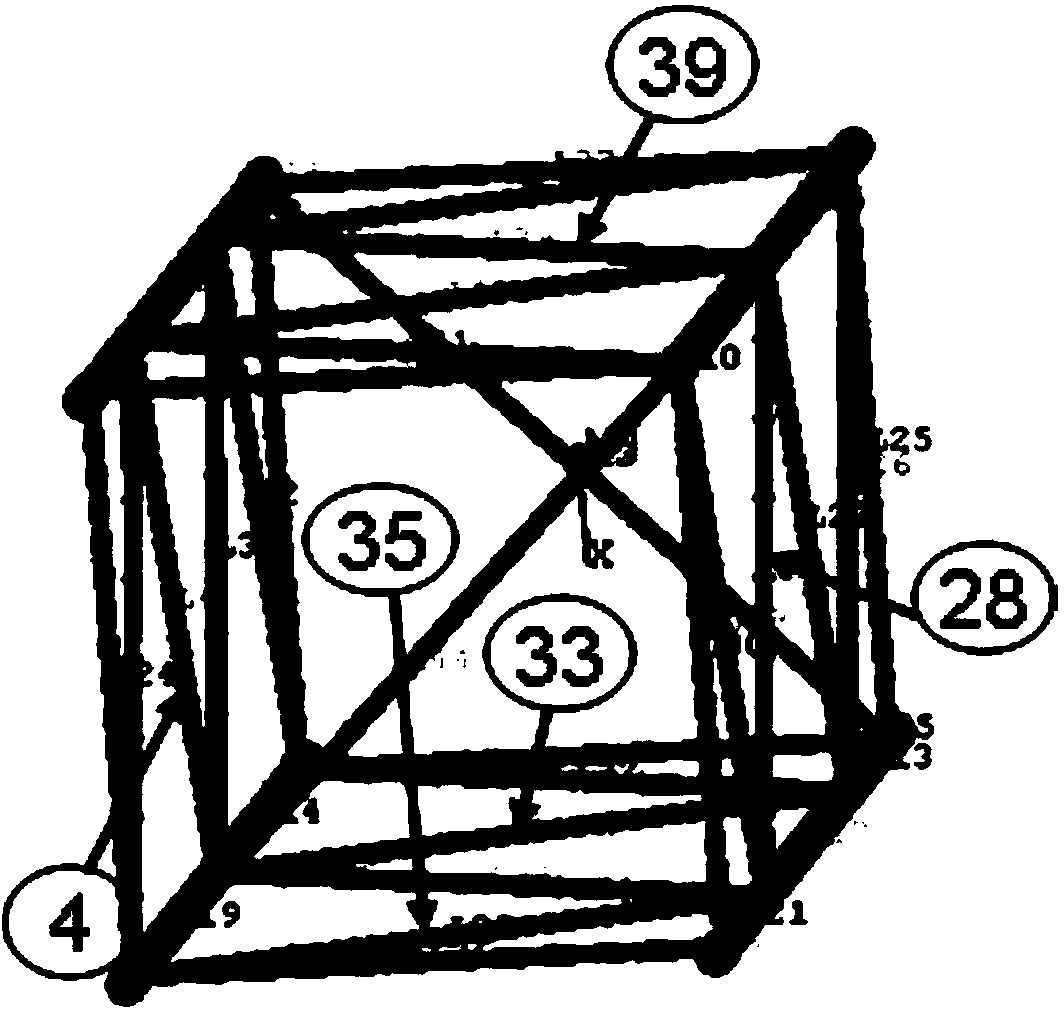

[0073] The truss arm in this embodiment is as Figure 11 As shown, it is a truss arm section welded by circular steel pipes. The ends of the four main chords at the right end are fixed, and the left end bears the torque, and the torque is applied through the thrust generated by two symmetrical oil cylinders, and the weak links of the structure are analyzed and determined. The material yield limit of the main chord of the jib section is 770MPa, the yield limit of the web tube material is 245MPa, the density is 7850kg / m3, and the elastic modulus is 2.1×10 11 , Poisson's ratio 0.3.

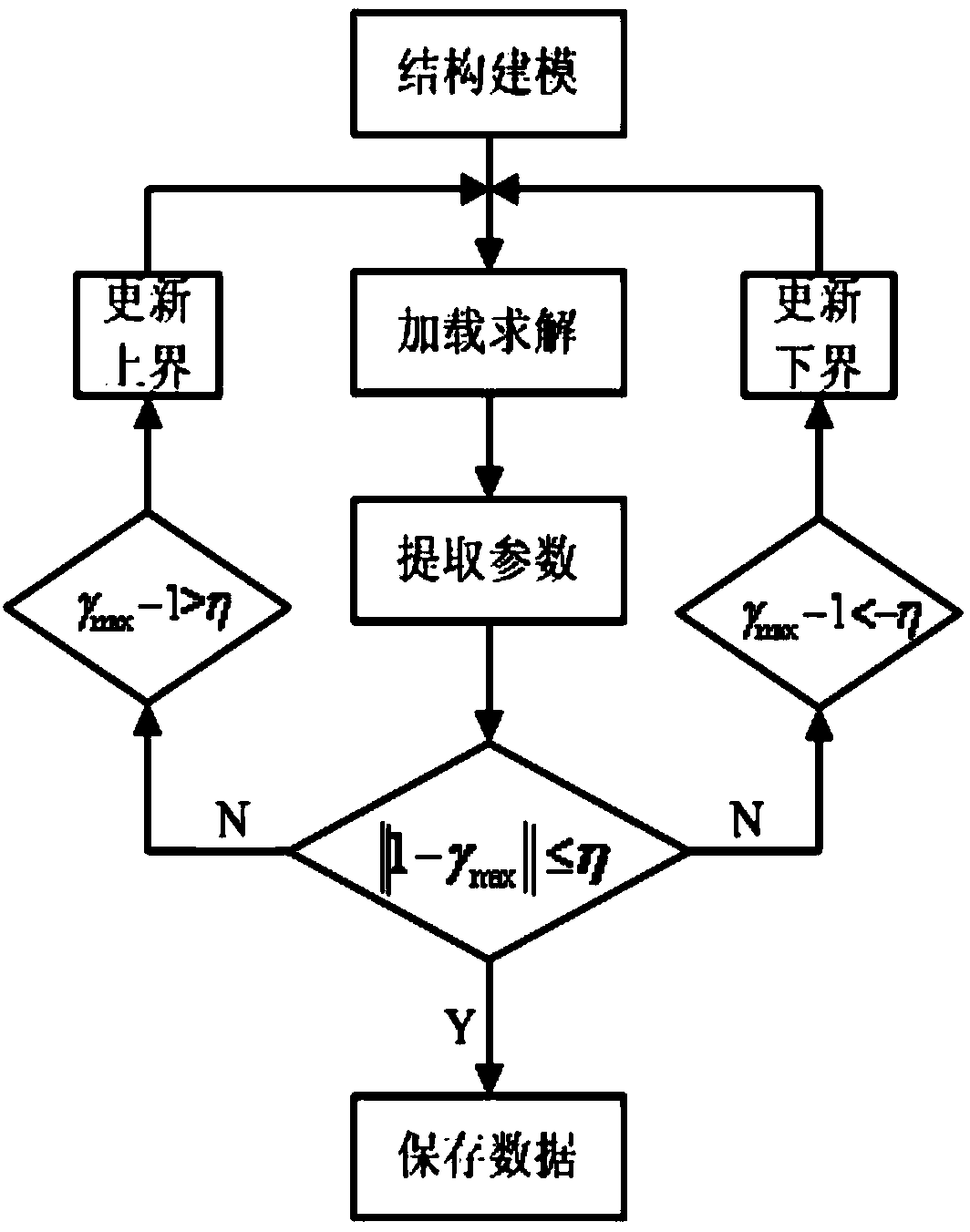

[0074] The method for determining the weak members of the truss structure in the above-mentioned hoisting and transporting machinery is carried out according to the following steps:

[0075] Step 1: Use the finite element software ANSYS to carry out parametric modeling, constrain all degrees of freedom at the right end of the arm section, and use the mass point Mass21 at the left end to couple the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com