PP/PA (polypropylene/polyamide) composite material and preparation method thereof

A technology of composite materials and mixed materials, which is applied in the field of polymer materials, can solve the problems of low notched impact strength, high price, and low impact strength, and achieve the effects of reducing production costs, improving notched impact strength, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

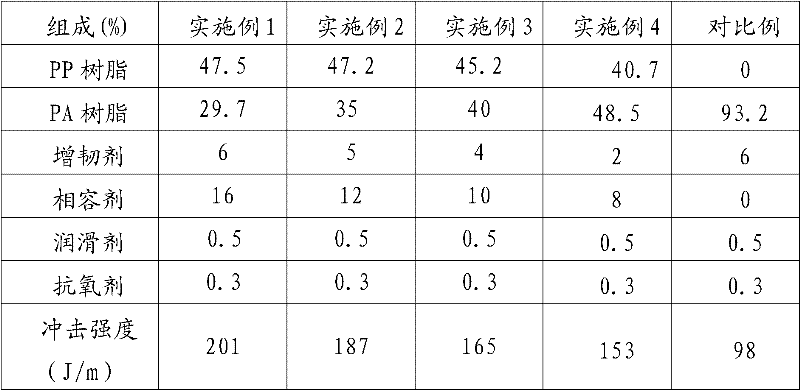

Embodiment 1

[0037] The raw materials were weighed according to the following proportions: PP resin 47.5%, PA resin 29.7%, toughening agent 6%, compatibilizer 16%, composite lubricant 0.5%, antioxidant 0.3%;

[0038] Pre-mixed raw materials, the mixing process is: first mix PP, PA resin, toughening agent at 100r / min for 1min; then add lubricant and other modification additives and mix at 500r / min for 3min to form a mixed material;

[0039] Put the mixed raw materials in a twin-screw extruder for melt extrusion and granulation. The temperature and process optimization of each section of the mixed material in the twin-screw extruder are: 180°C in the first zone, 240°C in the second zone ℃, 240℃ in the third zone, 240℃ in the fourth zone, 210℃ in the fifth zone, 210℃ in the sixth zone, 200℃ in the seventh zone, 210℃ in the eighth zone, and 230℃ in the head, the melt pressure is controlled at 2-4MPa, among which, the seventh zone Open the vacuum port for vacuuming; the screw speed of the twin-...

Embodiment 2

[0041] Raw materials were weighed according to the following proportions: PP resin 47.2%, PA resin 35%, toughening agent 5%, compatibilizer 12%, composite lubricant 0.5%, antioxidant 0.3%;

[0042] The preparation process is the same as in Example 1.

Embodiment 3

[0044] Weigh the raw materials according to the following ratio: PP resin 45.2%, PA resin 40%, toughening agent 4%, compatibilizer 10%, composite lubricant 0.5%, antioxidant 0.3%;

[0045] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com