Electrically-induced light-emitting line with arrow direction indication function

An electroluminescent wire, arrow direction technology, applied in electroluminescent light source, electric light source, light source and other directions, can solve the problem of unable to produce direction indication effect, unable to realize light with direction indication arrow pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

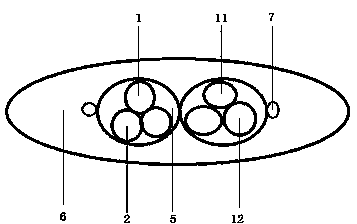

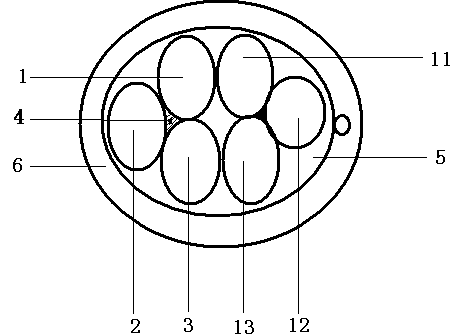

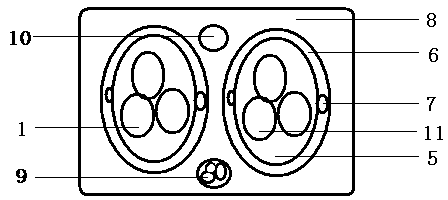

[0027] An electroluminescent wire with an arrow direction indication, which includes: two parallel multi-core luminescent wires, an external electrode 7, and a colored transparent plastic layer 6. The multi-core luminous wire is composed of more than one insulated metal wire. figure 1 The multi-core light-emitting structure diagram is composed of 1, 2, and 3, which are spirally wound or twisted according to the inclination angle, and the surface is coated with a light-emitting layer. The insulated metal wires in the two parallel multi-core luminescent wires are respectively combined according to the inclination angle to form a direction arrow, forming a "person" or "eight" shape, and the inclination angle is preferably equal to 45 degrees. And place the external electrode 7, the external electrode is closely connected with the light-emitting layer, and sealed with a colored transparent plastic layer. When a plurality of insulated metal wires and external electrodes are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com