Operation control panel

A console and controller technology, applied in electrical equipment shells/cabinets/drawers, electrical components, etc., can solve problems such as hidden safety hazards, damage to operating console instruments, etc., to eliminate hidden dangers of electrical safety and reduce maintenance. Number of times, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

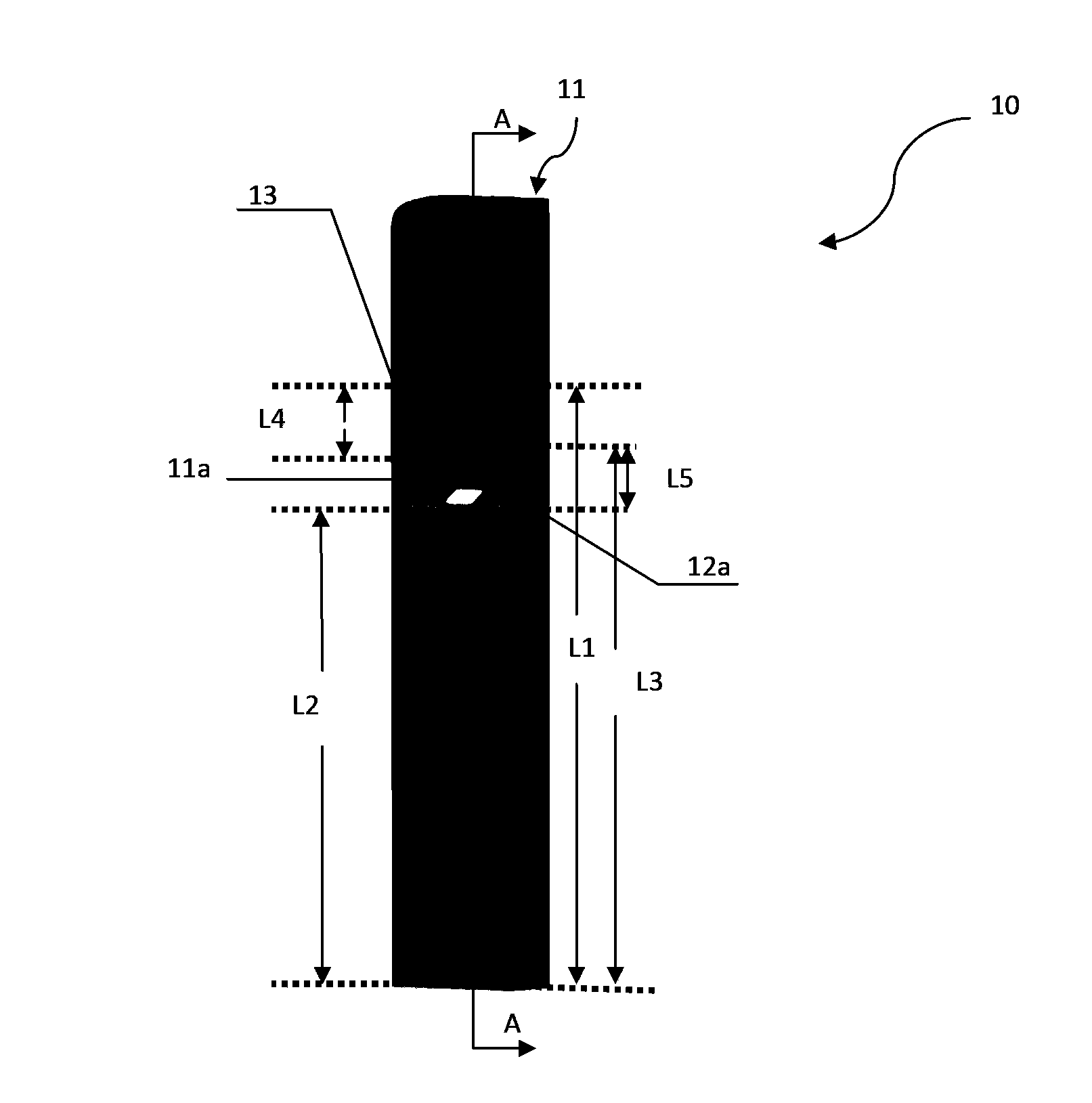

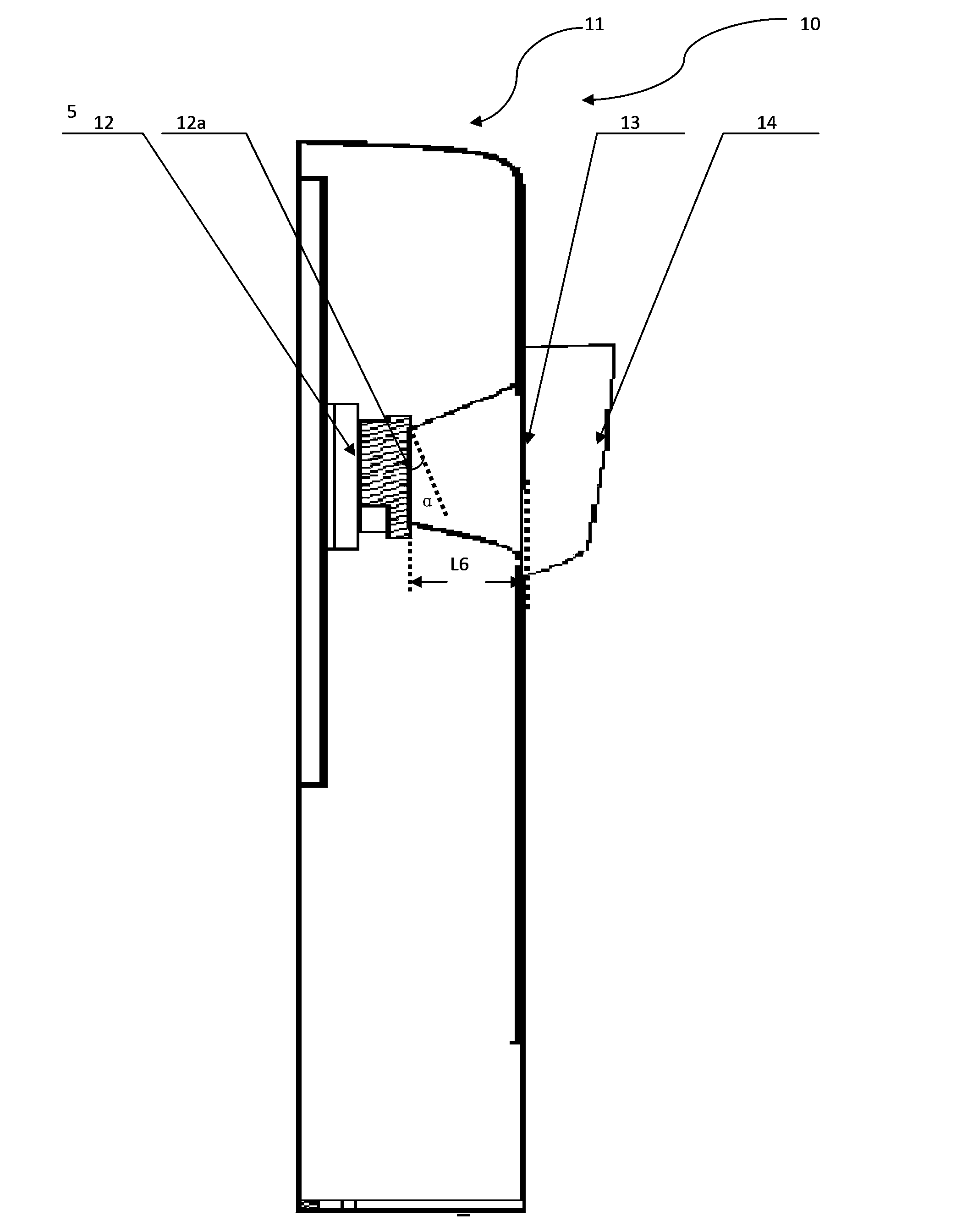

[0021] figure 1 It is the front view of the operation console involved in the present invention in the embodiment.

[0022] Such as figure 1 As shown, the operation console 10 contains a body 11, a controller 12 ( figure 1 Not shown in ) and transparent baffle 13.

[0023] The main body 11 has the appearance of a rectangular box and is made of plastic material. The distance L1 from the bottom end of the main body 11 to the upper end of the opening 11a is 1630 mm. The distance L2 between the bottom end of the main body 11 and the lower end of the opening 11a is 1266 mm, and the operation display screen 12a is placed in the opening of the opening 11a. The upper end of the opening 11a is sealingly combined with the upper end of the transparent baffle 13, and the left and right ends of the transparent baffle 13 are respectively sealingly combined with the left end and the right end of the opening 11a. The transparent baffle 13 is arranged opposite to the operation display scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com