Chair

A technology for chairs and components, applied in chairs, reclining chairs, rocking chairs, etc., can solve the problems of increasing the travel of moving parts, unable to make detailed adjustments, etc., and achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

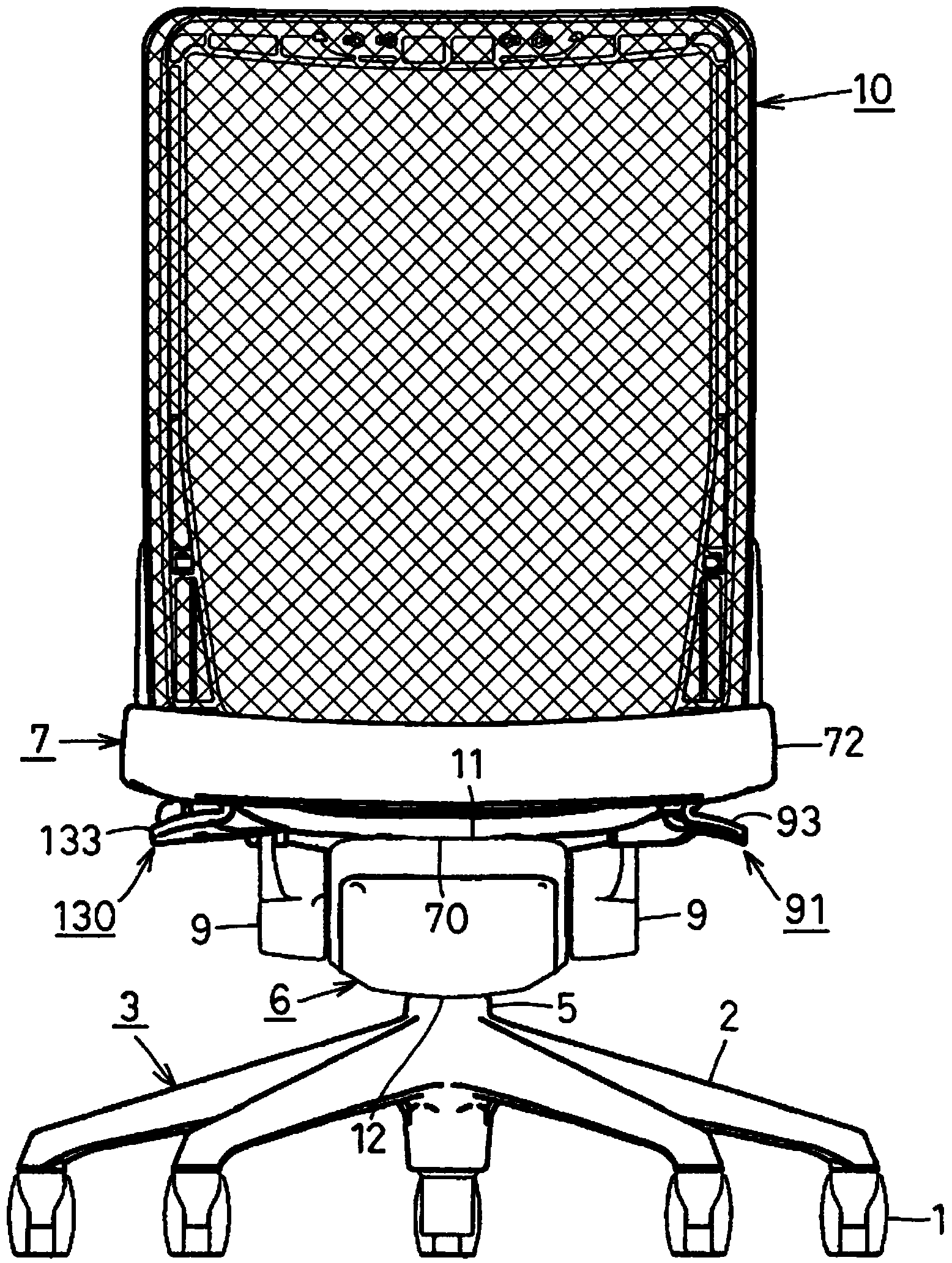

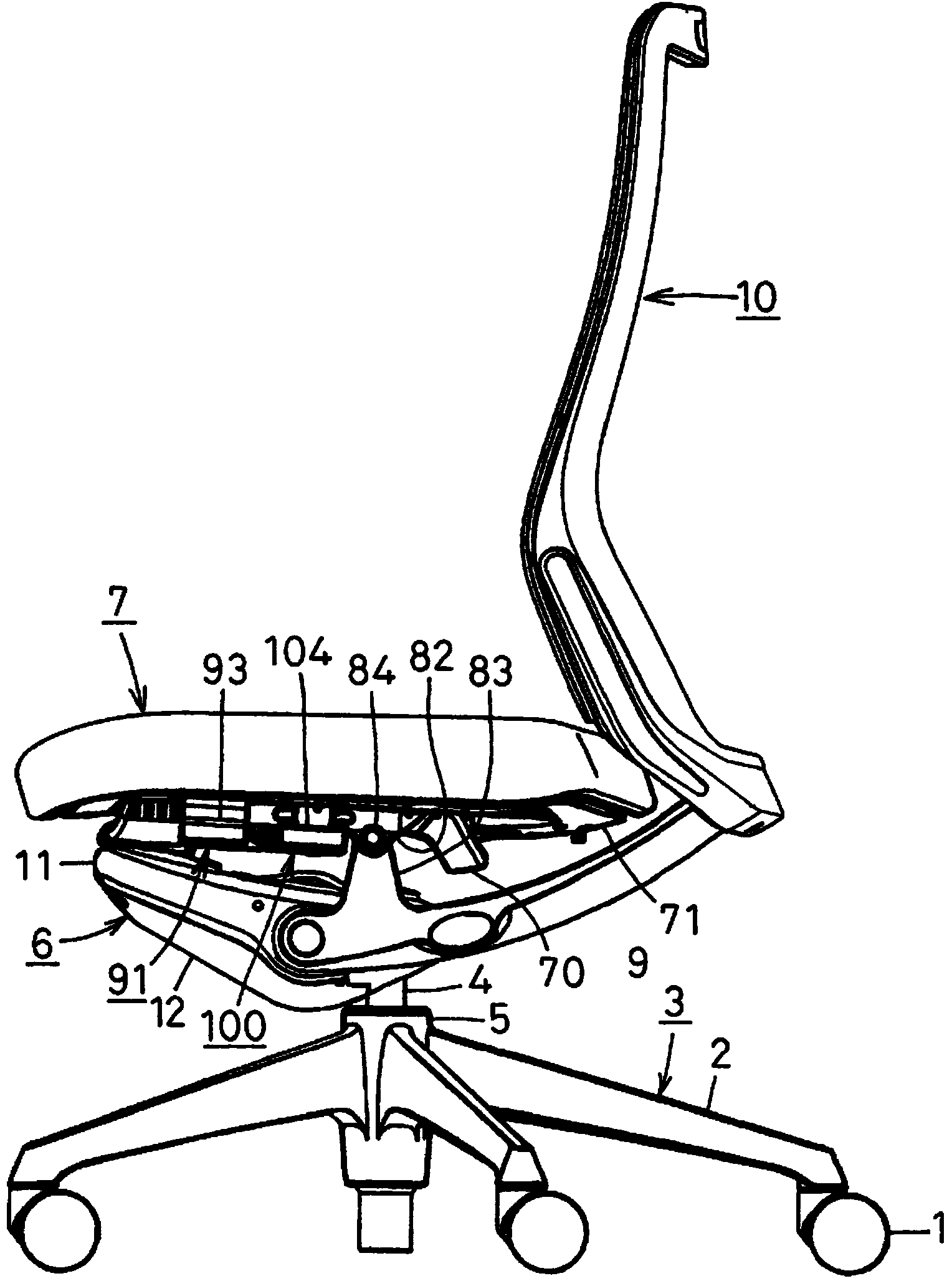

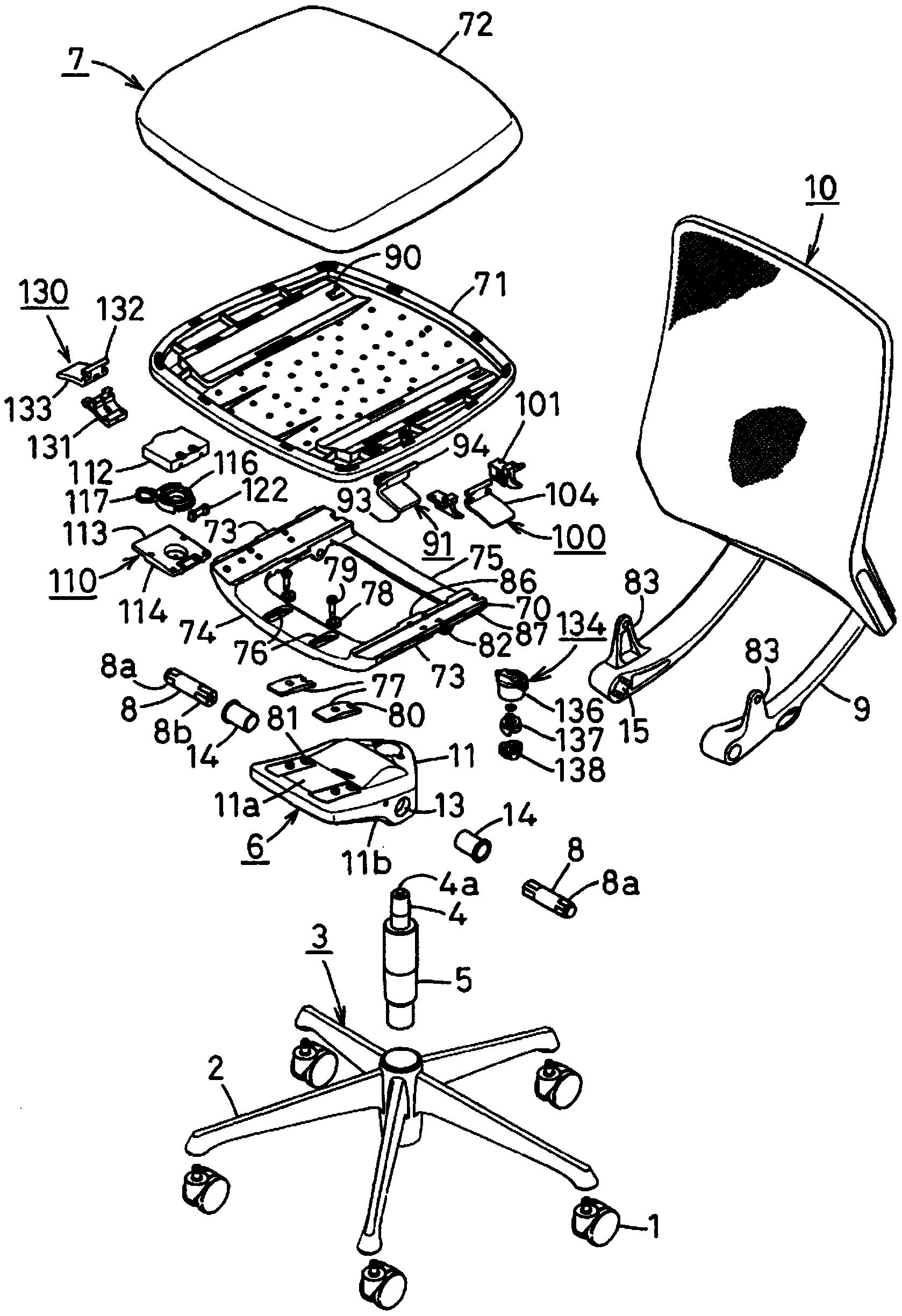

[0091] Hereinafter, one embodiment of the present invention will be described based on the drawings. In addition, in each figure, it refers to left and right when viewed from the front.

[0092] figure 1 is the front view of the chair of the present invention, figure 2 It is a side view of the chair of the present invention.

[0093] The chair is equipped with: a leg body 3 having five radial leg bars 2 equipped with casters 1 at the front end; (Gas Spring, see image 3 , Figure 14 etc.); the support 6 towards the upper front, its rear end is supported on the upper end of the foot column 4; the seat 7, which is supported above the support 6 as described later; the left and right pair of backrests towards the rear support Rods 9,9, their front ends are directed towards a left and right pair of pivots 8,8 (refer to image 3 , Figure 7 etc.) and are pivotally connected to the support 6; and the backrest 10, which is supported by the rear ends of the two backrest support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com