Metallic materials with excellent brazing properties

A metal material and brazing technology, which is applied in the direction of metal material coating technology, metal layered products, metal processing equipment, etc., can solve the problem of not fully showing the excellent corrosion resistance of galvanized steel and the corrosion resistance of galvanized steel Function and other issues, to achieve the effect of simplifying the brazing process, good lubricity and corrosion resistance, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment provides a metal material with excellent brazing properties. As an example, in this embodiment, No. 45 steel is used as the core material metal; a Sn-Pb-based solder foil layer is formed on one of its main surfaces , as an example, the solder selected here is HL600, and the thickness of the solder foil layer is 0.05 mm. And also form zinc phosphate film layer by conventional phosphate treatment method, and the adhesion amount of described zinc phosphate film layer is 20g / m 2 Then, the core material metal formed with a phosphate film layer is immersed in a passivation solution, wherein the temperature of the passivation solution is 80° C., and the treatment time is 4 to 6 minutes; the adhesion amount of the formed passivation film layer is about 5g / m 2 . The only difference between the samples and the comparative samples is the composition and / or content of the passivation solution.

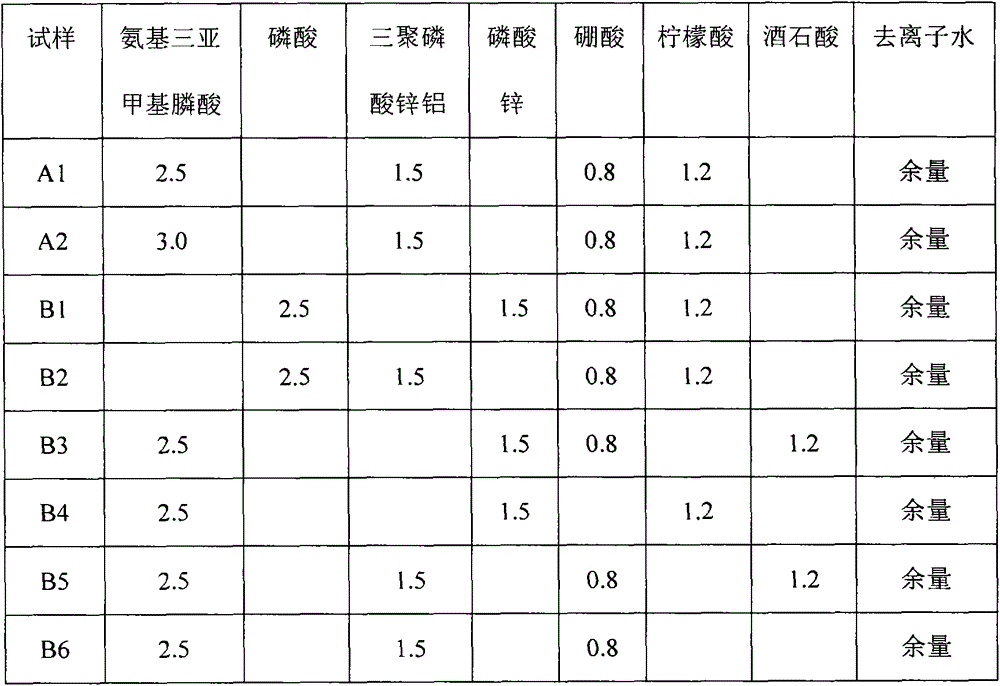

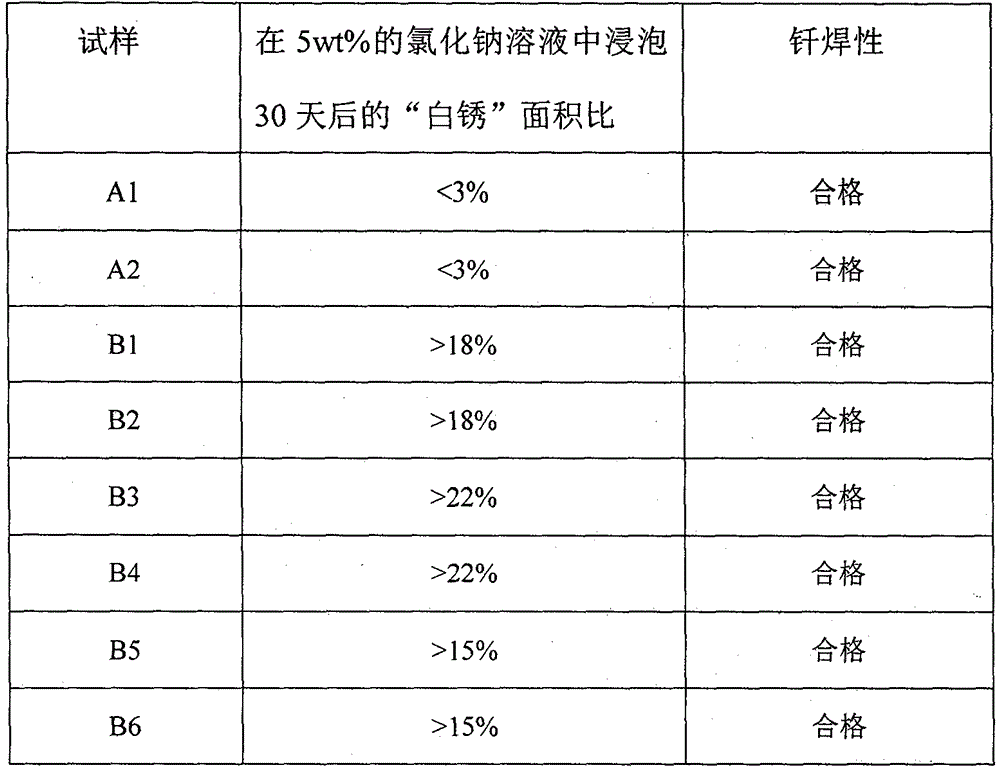

[0019] Table 1 shows the composition of the passivation solution use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com