Code printing machine

A technology of coding machine and inkjet head, applied in the field of coding machine, can solve the problems of inconvenient adjustment of conveyor belt height and inclination angle, disadvantageous working efficiency and coding quality of coding machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

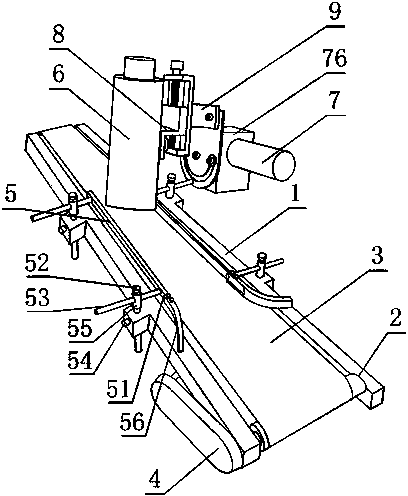

[0028] like Figure 1 to Figure 3 , a coding machine provided by the present invention includes a platform for material transfer, an inkjet head 6 arranged above the platform, and a mounting frame 7 for fixing the inkjet head 6. The platform includes a platform frame 1, a set At least two pulleys 2 parallel to each other on the platform frame 1 and the conveyor belt 3 wound on the pulley 2 also include an inkjet head connection block for adjusting the height and inclination of the inkjet head 6 relative to the mounting frame 7 8 and the adjustment part 9, the two sides of the inkjet head connection block 8 are respectively connected with the inkjet head 6 and the adjustment part 9, the adjustment part 9 is fixedly connected on the mounting frame 7, and the platform frame 1 on both sides of the pulley 2 Each is provided with a limiting device 5 for limiting the moving path of the material on the conveyor belt 3 .

[0029] Specifically, the set limit device 5 is used to limit t...

Embodiment 2

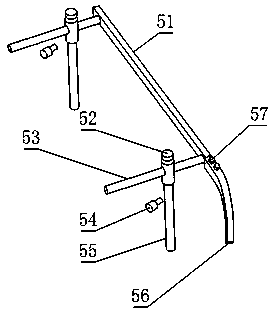

[0031] This embodiment is further limited on the basis of embodiment 1: as Figure 1 to Figure 3 , the limiting device 5 includes a bar-shaped or plate-shaped block 51 perpendicular to the axis of the pulley 2, the block 51 is fixedly connected with a horizontal slide bar 53 whose axis is parallel to the axis of the pulley 2, and the platform frame 1 is also A through hole with the axis in the vertical direction is provided, and a column 55 which is fitted with a gap is arranged in the through hole, and a height adjustment bolt 54 which is threadedly connected with it is also provided on the platform frame 1, and the thread of the height adjustment bolt 54 The end portion is in contact with the column 55, and a slide bar hole is arranged above the column 55. The horizontal slide bar 53 and the slide bar hole form a clearance fit, and the column 55 is also provided with a width adjusting bolt 52 threaded therewith. The threaded end of the width adjusting bolt 52 is in contact w...

Embodiment 3

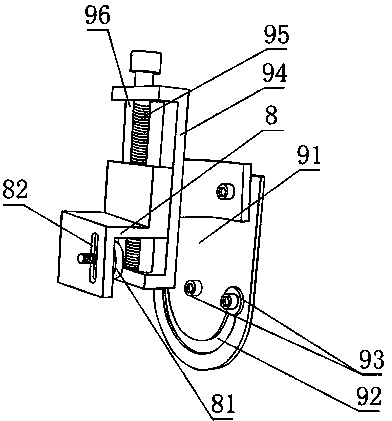

[0036] This embodiment is further limited on the basis of embodiment 1: as Figure 1 to Figure 3 , the adjustment part 9 includes a height adjustment part 94 and an angle adjustment part 91 fixedly connected with the height adjustment part 94, the height adjustment part 94 is provided with a height fine adjustment bolt 95 and a guide rod 96, and the two ends of the guide rod 96 Fixedly connected on the height adjustment part 94, the height adjustment part 94 is also provided with a bolt hole, the height fine adjustment bolt 95 is partially located in the bolt hole, and the height fine adjustment bolt 95 can rotate around the bolt hole and the height fine adjustment bolt 95 The positional relationship relative to the height adjustment part 94 does not change, the height fine adjustment bolt 95 and the guide rod 96 are parallel to each other, the inkjet head connection block 8 is threadedly connected with the height fine adjustment bolt 95, and the inkjet head connection block 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com