Preparation method of unbonded-phase ultrafine WC hard alloy

A technology of cemented carbide and no binder phase, which is applied in the field of preparation of ultra-fine WC cemented carbide without binder phase, and achieves the effects of excellent comprehensive performance, good comprehensive performance, and avoiding uneven growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

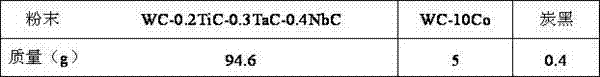

Embodiment 1

[0021] (2) The mixed powder is subjected to high-energy ball milling in a high-energy ball mill using cemented carbide balls. The speed of ball milling is 360 r min -1 , the ball milling time was 48 h, after the ball milling, the powder was vacuum-dried, ground and sieved.

[0022] (3) Hot pressing sintering of powder. Hot pressing temperature: 1750 ℃, holding time: 60 min, hot pressing pressure: 20 MPa.

[0023] (4) Measure the grain size and detect the mechanical properties of the sintered samples. The fracture toughness of the as-prepared superfine WC cemented carbide without binder phase is 7.15 MPa·m 1 / 2 , the Vickers hardness is 3150 HV 0.05 , the transverse fracture strength is 910 MPa, and the grain size is 390 nm.

[0024] Example 2:

[0025] (1) Weigh the mass of each powder component according to the mass percentage distribution (take the total powder mass of 100g as an example):

Embodiment 2

[0027] (2) The mixed powder is milled in a high-energy ball mill with cemented carbide balls at a speed of 300 r min -1 , the ball milling time was 36 h, after the ball milling, the powder was vacuum-dried, ground and sieved.

[0028] (3) Hot pressing sintering of powder. Hot pressing temperature: 1750 ℃, holding time: 60 min, hot pressing pressure: 20 MPa.

[0029] (4) Measure the grain size and detect the mechanical properties of the sintered samples. The fracture toughness of the as-prepared superfine WC cemented carbide without binder phase is 7.15 MPa·m 1 / 2 , the transverse fracture strength is 964 MPa, and the Vickers hardness is 3450 HV 0.05 , with an average grain size of 420 nm.

[0030] Example 3:

[0031] (1) Weigh the mass of each powder component according to the mass percentage distribution (take the total powder mass of 100g as an example):

Embodiment 3

[0033] (2) The mixed powder is milled in a high-energy ball mill with cemented carbide balls at a speed of 250 r min -1 , the ball milling time was 72 h, after the ball milling, the powder was vacuum-dried, ground and sieved.

[0034] (3) Preparation of powder compact. Compression pressure: 100 MPa.

[0035] (4) Vacuum pre-sintering of powder compacts. Sintering temperature: 1700 ℃, sintering time: 1 h.

[0036] (5) Hot isostatic pressing of vacuum pre-sintered body. Hot isostatic pressing temperature: 1550 ℃, hot isostatic pressure 1000 MPa, time: 1 h.

[0037] (6) Measure the grain size and detect the mechanical properties of the sintered samples. The fracture toughness of the as-prepared superfine WC cemented carbide without binder phase is 7.85 MPa·m 1 / 2 , the transverse fracture strength is 1178 MPa, and the Vickers hardness is 3050 HV 0.05 , with a grain size of 480 nm.

[0038] Example 4:

[0039] (1) Weigh the mass of each powder component according to the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com