Manufacturing method of silicon germanium heterojunction bipolar transistor device

A technology of heterojunction bipolar and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as low etching rate, affecting process stability, and large total width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments of the present invention are disclosed below; however, it is to be understood that the disclosed embodiments are merely exemplary of the invention, which may be embodied in various forms. Therefore, specific structural and functional details disclosed herein are not to be interpreted as limiting. Further, the terms and terms used herein are not limiting; rather, they provide an understandable description of the invention. The present invention will be better understood by considering the following description in conjunction with the accompanying drawings, wherein like reference numerals represent the same meaning. The drawings are not to scale.

[0046] A manufacturing method of a silicon germanium heterojunction bipolar transistor device according to a preferred embodiment of the present invention includes the following steps:

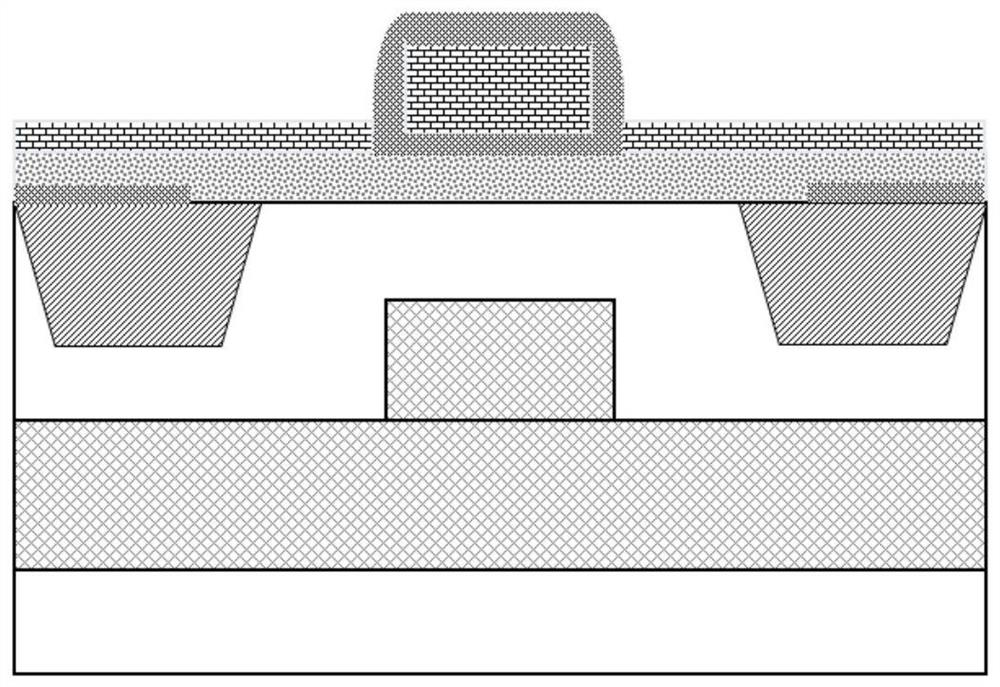

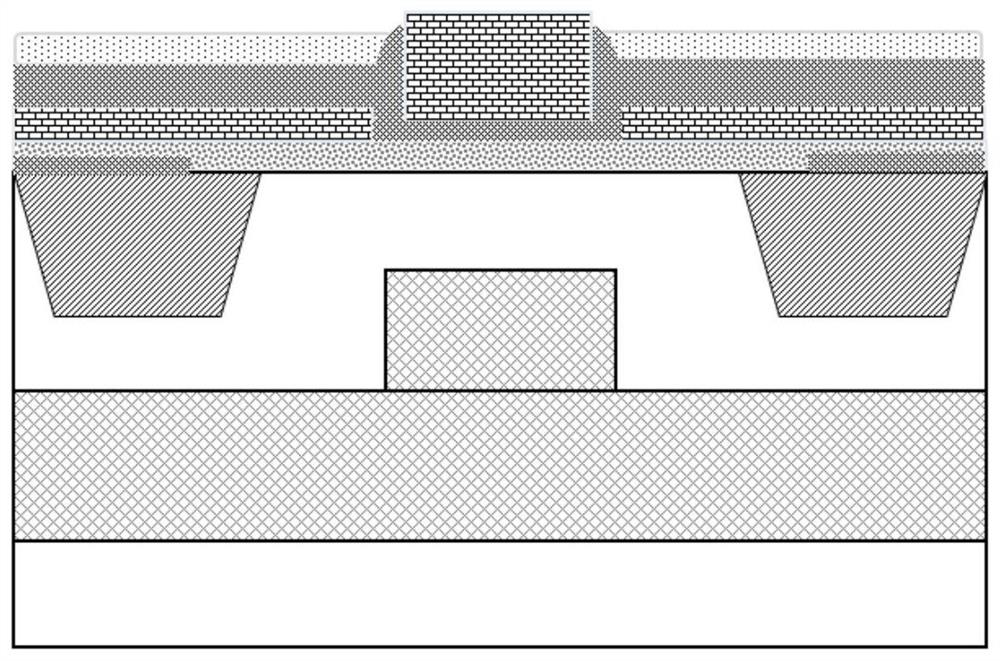

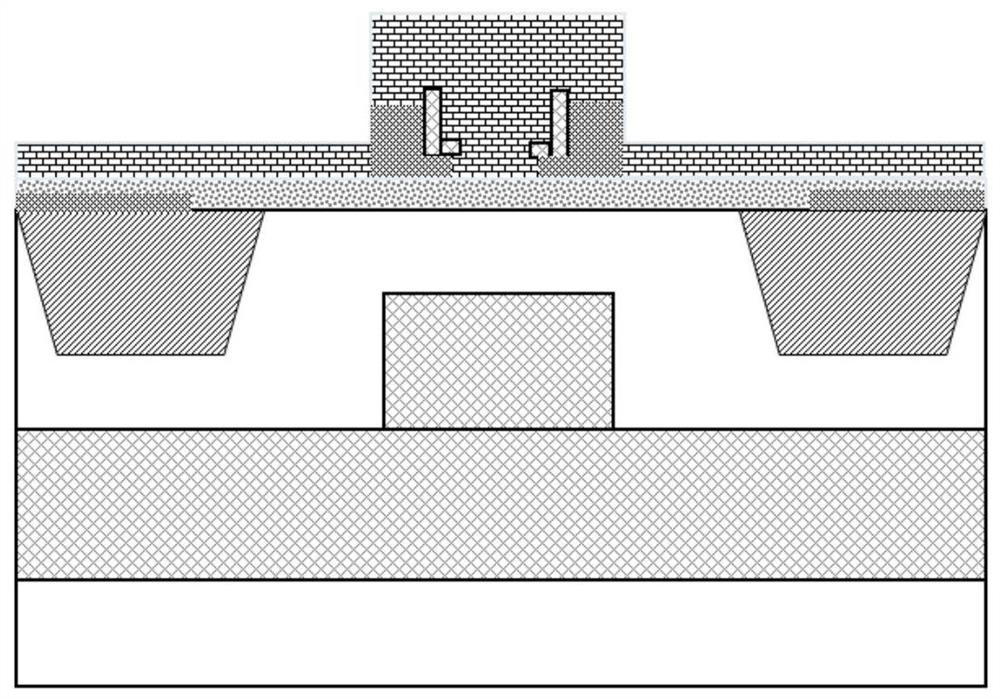

[0047] step one, as Figure 4-5 As shown, after the collector electrode is formed and the non-selective SiGe base regi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com