High-speed train brake disc and brake disc material thereof

A technology for high-speed trains and brake discs, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of not meeting the braking requirements of high-speed trains, accelerating the occurrence probability and expansion speed of thermal cracks, and unfavorable braking conditions. To improve the mechanical properties and corrosion resistance, high strength, high hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

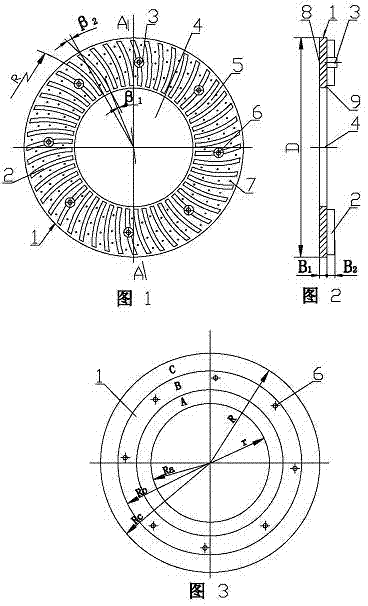

[0029] Such as figure 1 , figure 2 The high-speed train brake disc shown has forced heat dissipation ribs, and the high-speed train brake disc includes a disc-shaped disc body 1. The disc body 1 has a disc body friction surface 8 and a disc body located on the opposite side of the disc body friction 8. On the back side 9, eight installation hole bosses 3 are evenly distributed on the back side 9 of the disk body, on which installation hole bosses 3 are provided with installation holes 6, and at the center of the disk body 1 is also provided with a disk body center hole 4, The outer diameter D of the disc body 1 is 695 mm, the inner diameter of the central hole 4 of the disc body is 378 mm, and the diameter of the mounting hole 6 is 15 mm.

[0030] There are 48 heat dissipation ribs 2 evenly distributed on the back surface 9 of the disk body, and the distance between two adjacent heat dissipation ribs 2 is 7.5° along the circumferential direction of the disk body. The cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com